Cost-effective consistency measurement for pulp and paper

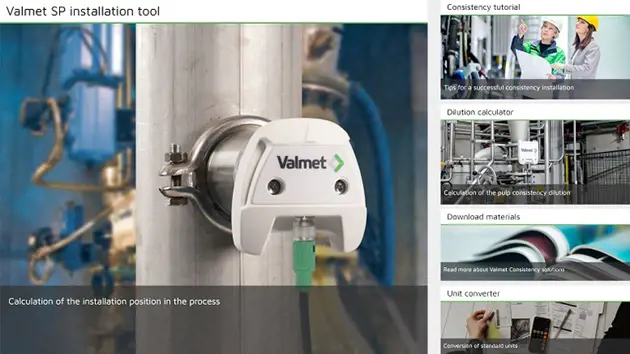

Valmet Blade Consistency Measurement - Valmet SP

Valmet Blade Consistency Measurement (Valmet SP) is the most used consistency measurement worldwide. With decades of experience and proven performance built-in, the Valmet SP offers accuracy, reliability and the longest lifetime.

Wide applicability - Suitable for all process flows in pulp and paper operations

Quick startup - Simple installation and startup with preset calibration curves

Low maintenance - No moving parts and no preventative maintenance required

Minimal investment for excellent accuracy

The 4th generation Valmet Blade Consistency Measurement is the most cost-efficient consistency measurement on the market for pulp and paper. With the latest technology, our patented internal detection principle and a modern user interface, it is highly accurate yet easy to commission and maintain thanks to preset calibration curves.

The Valmet SP measures fiber consistency using shear force. In addition to improved accuracy, the latest iteration of the Valmet SP features even better reliability with improved sealing, higher temperature compatibility, and noise immunity. With no need for water or air supply, installation is hassle-free and power consumption low.

Measure consistency in any pulp and paper process

The Valmet SP is truly a universal consistency measurement solution. Our portfolio of options, including a variety of sensing elements, allows you to configure the sensor for practically any pipe size and layout.

With a consistency measurement range from 0.7 to 16%, the Valmet SP is the most important part of an automatic consistency control loop. The Valmet SP is suitable for chemical kraft pulp, mechanical pulp, recycled pulp, DIP, OCC and so forth. It can be used in the blow line, screening, washing, bleaching, refining, stock preparation, mixing and machine chest. You get a stable and accurate measurement even when process conditions have variations.

For optimal performance, the Valmet SP should be installed where the process has a laminar flow. Turbulence reducers are available to further stabilize measurement in challenging locations.

The freely available Valmet Measurement Advisor can be used to determine the best installation position and Valmet SP model. The tool also provides tailored installation instructions for specific process conditions.

Simple operation

Valmet Link is the new operator terminal for Valmet SP. A user-friendly graphical display and keyboard provide easy, intuitive operation. In addition to simple single-point calibration, operators get a clear overview of measurement trends and results.

Pre-programmed calibration curves make it easy to get the best performance from Valmet SP. When running different pulp grades in the same process, up to eight calibrations can be stored in different recipes and selected remotely or directly at the Valmet Link display. Results from detailed self-diagnostics are easily accessible from Valmet Link as well.

The Industrial Internet ready Valmet Link can be adapted to different communication standards with plug-in components, including remote communication connections.

Valmet Measurement Advisor

Valmet Measurement Advisor is a tool developed to help you select the most applicable installation position for Valmet Blade Consistency Measurement in the process.

Read more

User Manuals

In our Customer Portal you will be able to find the user manuals you are looking for. The manuals are available in several languages and can be easily downloaded.

Customer Portal