Augmented reality – the new era in mill maintenance

VR, AR, MR, XR… Does it feel like the virtual world is difficult or even pointless to enter? If the answer’s yes, now’s the time to do something about it. Virtual tools are making a breakthrough in the industrial environment, bringing possibilities never seen before. At the same time, the development of new technologies and software is evolving rapidly. Virtual reality can help to visualize complex industrial environments, streamline maintenance, enable remote support, and decrease costs at mills and plants, to name just some examples.

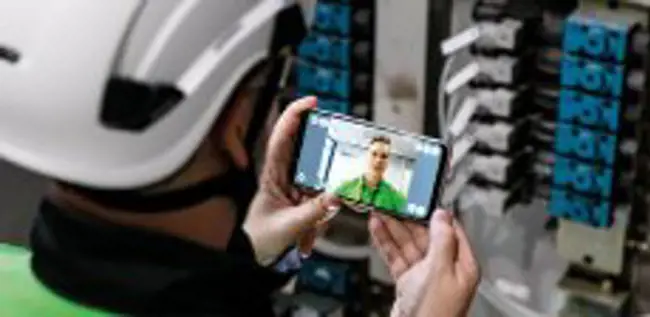

Augmented reality (AR) can be a valuable maintenance tool. Unlike virtual reality (VR), which creates a totally artificial environment, augmented reality uses the existing environment and overlays new information on top of it in real time. It enables a new kind of access to information when performing maintenance tasks. With the help of AR, process information can be detached from control rooms, and mechanics can take the information they need with them when they’re working on a machine. The benefit is that the information is connected with the actual reality – when looking at the machine, the mechanic can see the selected information for the process stage in question, as well as required additional information like installation instructions.

With AR, most preventive measures can be checked fluently with “hands-off” instead of “hands-on” repairing procedures. All the repairs due can be predicted and scheduled well before possible failures happen, and this approach will obviously have a huge impact on plant reliability and production uptime.

Technicians can also shoot 360-degree video when tackling a task for the first time with a more experienced worker. When executing the task alone, they can verify the different stages of the work using AR devices. This is one way to ensure consistently good results in maintenance work, while taking safety issues into account. In addition, an interactive Digital Twin can be used with 3D model to explore and learn device functionality.

For the first-timer, navigating in virtual surroundings may feel a little awkward, but when they’ve gotten used to the headset and control stick, the journey begins to feel fun and fascinating!

Related articles