Easier and safer than ever to run and maintain, for unparalleled user-friendliness

Sep 23, 2021

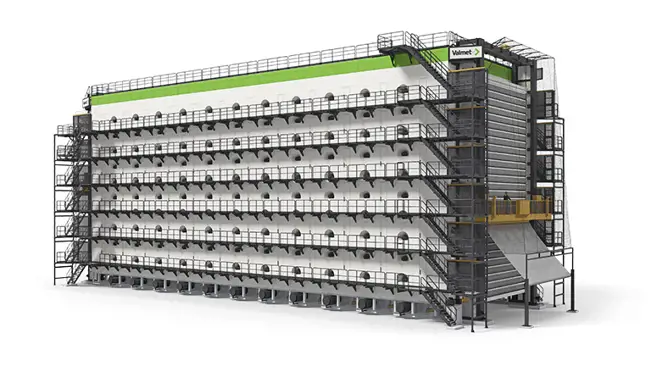

The Valmet Airborne Dryer is designed for maximum user-friendliness, with smart innovations based on proven technology making operation easier and safer than ever before.

|

“We listened to our customers and developed the latest Airborne Dryer according to their views and wishes. This means that it is now even easier to run and maintain. The number of operators needed to run the dryer is kept to a minimum, and it is designed to provide comfortable working conditions with minimal dust, low temperature and low noise levels. At the same time, safety has become even better. So it’s with great pleasure that we introduce this dryer that sets the new standard on today’s market,” comments Tommi Kyläniemi, El&A Technology Manager at Valmet. |

Automatic tail threading and quick access hatches raise efficiency

Problems with tail threading are often the main reason it takes an unnecessarily long time to get production rates back up after a stop. To solve this, automatic tail threading from press section to the dryer has been added. This means the time to get back up to full production speed is no longer limited by the manual tail threading to the dryer, so high production can be reached almost immediately. A rotating aluminum roller support at the dryer inlet also increase operational reliability and safety by minimizing dust formation.

To simplify access for operators, new fold-up hatches made of flexible material that are simple and safe to open have been added. These provide both good visibility into the dryer and ideal conditions to perform fast and safe maintenance work. “Thanks to the flexible material, they are very quick to open, averaging only 20 seconds to open them all at the same time,” says Kyläniemi.

Simplifying the operator’s work

Tommi Kyläniemi also highlights the upgraded movable platform in the wet and dry ends that is more flexible than previous versions. The movable platform, which is highly appreciated by operators, allows them to get much closer to the dryer than before. And while they are working, the photocells make sure the platform cannot be moved, to simplify the work process and increase safety.

Another new feature that increases both user friendliness and safety is automatic locking of the upper blow boxes in the open position. Since this was something operators had to do manually before, it is now easier and more secure.

|

Smart performance monitoring The dryer is equipped with cutting-edge technology that is of great benefit to both performance and user-friendliness. New camera surveillance makes performance monitoring better than ever, with the operator able to get key information directly in his smartphone via Valmet's Industrial Internet platform, which can be tailored to each customer. |

|

“Performance monitoring is a great asset for operators. They can now get real-time information on parameters such as evaporation capacity, electricity consumption and filter cleaning. This means they stay a step ahead when problems need to be fixed or when it is time for planned maintenance work. The data collected is also used for analysis and development of the drying process so that even better drying capacity and user-friendliness can be achieved,” explains Kyläniemi.

New light-weight aluminum hatch for Airborne pulp dryers

In addition to the fold-up hatches, Valmet offers a new light-weight aluminum hatch type. These are easy to handle compared to, for example, steel hatches because of their size and weight. They are easy to install also in existing dryers and no separate locking device is needed, thanks to spring-loaded hinges.

Separate hatches for each drying deck facilitate safe broke handling and makes checking and cleaning easy. In addition, the tail threading can easily be followed.