Press roll covers for board and paper making

For optimal dewatering and improved machine runnability

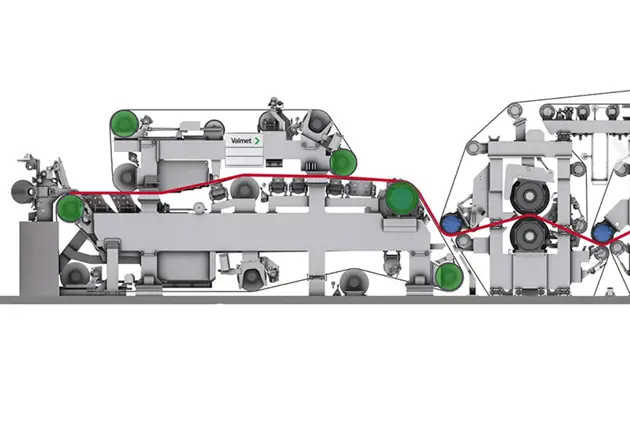

Roll covers in the press section have a significant impact on production line efficiency, capacity, and product quality. Together with press section clothing, they are key components for dewatering during the wet pressing process. In center roll-based presses with an open draw, roll covers also play a critical role in machine runnability. With our innovative Bioneer roll covers, you can additionally reduce your climate impact.

Reduced downtime

Increased production

Savings in energy consumption

Roll covers tailored for your needs

Roll covers tailored for your unique needs

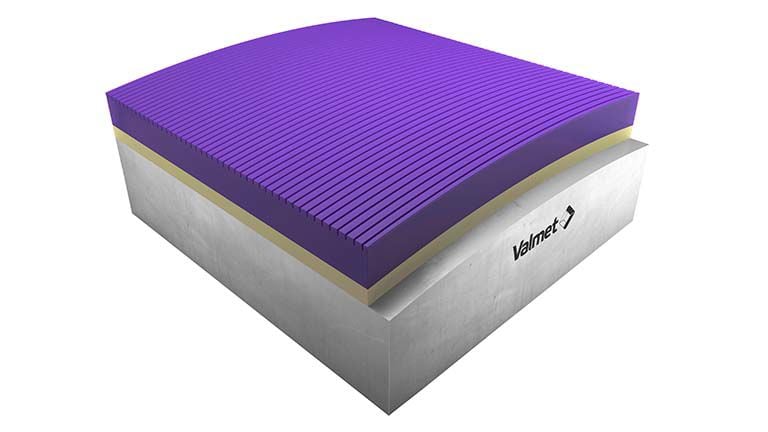

Valmet press roll covers range from economical rubber covers for less demanding applications, to the toughest roll covers providing the most efficient dewatering technology. Covers can be designed for the unique needs of any application. Cover topography can be tailored for maximal dewatering, and non-felted rolls can have surfaces with release characteristics adjusted for the specific grade being produced.

Valmet offers soft press roll polyurethane covers for demanding process conditions such as LNP rolls and suction press rolls. They can operate under the highest loads and at the highest speeds, and still save energy and require less maintenance.

For grades requiring more gentle nip pressures (e.g. to achieve bulk savings), soft but still extremely durable roll covers can be applied without sacrificing roll reliability and run period lengths.

Bioneer roll cover family - Sustainable innovation for press sections

Valmet’s Bioneer roll covers provide a more sustainable alternative to conventional press roll covers by incorporating recycled, renewable or bio-based materials - enabling Valmet and its customers to reduce reliance on fossil resources. Bioneer roll covers are accompanied with life cycle assessments, providing product-specific data on their climate impact.

Request the LCA here

Environmental benefits of Valmet Press Roll Cover PF Bioneer

- Achieve up to 12,2% lower CO2 emissions (cradle-to-gate) compared to

a standard product - REDcert2 –certified renewable (bio-based) and/or recycled material through a mass balance approach*

- First press roll covers with verified climate impact through third-party assured life cycle assessment (LCA)

Download Press Roll Cover PF Bioneer brochure from Solution Finder.

*Mass balancing is a method for mixing fossil and renewable/recycled/bio-based raw materials in production, offering a means to reduce the overall share of fossil materials in products.

Environmental benefits of Valmet Press Roll Cover VT-W Bioneer

- Recycled and bio-based materials 56%

- Transparently communicated climate impacts through self-declared life cycle assessment (LCA)

Download Press Roll Cover VT-W Bioneer brochure from Solution Finder.

Example: Total cradle-to-gate emissions for Press Roll Cover PF Bioneer, kgCO2e/1 m2 of product, calculated with 5 P&J hardness

Optimize wet pressing for energy savings and capacity increase

A key to higher energy efficiency, and often a significant enabler of a capacity increase, is optimal wet pressing performance. Increased nip dewatering improves drying capacity and increases sheet dryness, with a remarkable effect on energy costs. For example, increasing post-press dryness by 1.5 percent unit means savings of approximately €1.3 million in drying energy costs (case linerboard 400,000t/a).

Reduce CO2 emissions and drive energy with advanced polyurethane covers

The latest polyurethane press roll cover products like the Valmet Press Roll Cover PP and PK have a lower friction coefficient, thanks to intensive R&D work that has resulted in lower rotation resistance under high nip loads and thus a reduction in the press drive’s power consumption. Allowing for a 15% reduction of drive energy compared to typical rubber, CO2 reduction -0.2 kg/t per roll.

Find optimal roll covers for every board and paper process

Explore our press roll cover products from interactive demo. By exploring this roll cover application tool you can easily see different cover options for every board and paper making process.

Start exploringQuestions about roll covers?

Answer a few questions and our roll experts will contact you shortly.

Contact usReferences and articles

keyboard_arrow_leftBack

{{currentHeading}}

{{productForm.Name}} {{"("+productForm.Size+")"}}