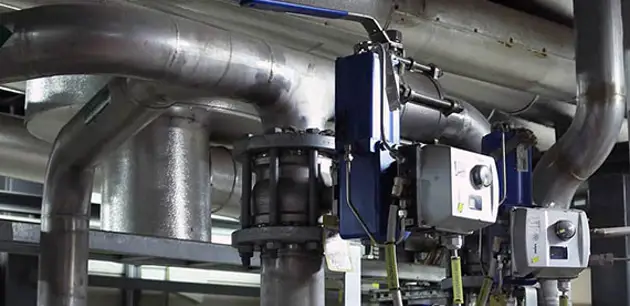

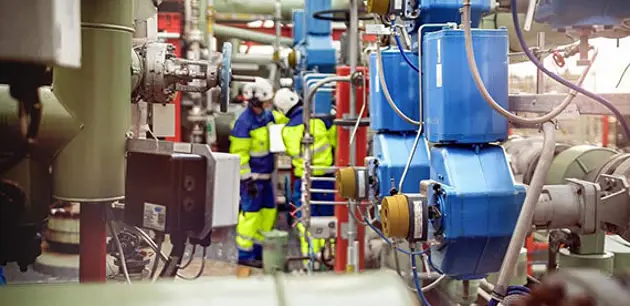

You can avoid downtime due to valve failure by having easy access to information about critical parameters. Using Wireless Link you can remotely monitor valve function and access difficult to reach communication and control modules safely and conveniently even up to 50 meters away.

Easy, safe and secure access with Wireless Link

You can set the sensors from a remote location using the Wireless Link app on an iPhone or iPad without ever opening the cover. This option is available in our Stonel™ Axiom™, Eclipse™ and Prism™ platforms for AS-interface and DeviceNet bus networks and in the Axiom and Eclipse platforms for conventional applications. Sustainable, yet profitable performance is a result of design and engineering aimed at minimized emissions and reduced size, weight and complexity.