Uncompromised roll cover performance for sizing and coating

Valmet is the market leader in film coaters and sizers, and has developed a great deal of related process know-how. We have put this expertise to good use in developing new roll cover materials that deliver uncompromised sizing and coating performance with both grooved and smooth rods, as well as with coating blades.

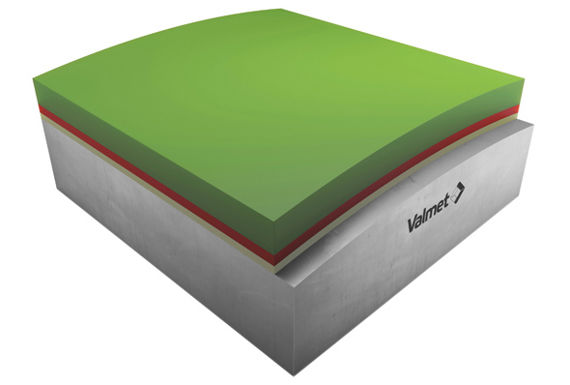

Valmet Sizer Roll Cover CF, our polyurethane cover with excellent wear resistance, features high-quality coating film formation for worry-free operation. Continuous development of this cover has improved its durability, and now with an extended hardness range. Valmet Sizer Roll Cover CF is also the best-performing cover for film sizing.

The same expertise allows us to offer an unmatched backing roll cover for blade coaters: Valmet Coater Roll Cover CC.

Film coating: a patented anti-scratch solution

Film coating with smooth rods raises the challenge of scratch resistance, as pigment coating particles tend to scratch the smooth cover and spoil the coating surface. Many papermakers have experienced this problem with competing covers. Valmet’s patented solution prevents scratching and provides the highest coating grammage possible, without any orange peel or other surface defects.

Film sizing: unprecedented features

To work in film sizing, the cover must be able to withstand the contact of the grooved rod without the rod or cover wearing out, and without changing the CD profile of the sheet. The cover also needs to be compatible with the sizing chemicals and process temperatures being used. The reliable Valmet Sizer Roll Cover CF incorporates all of these features.

Swing machines: double your advantage with Valmet’s PU sizer cover

No universal covers have previously been available for swing machines, alternating between film coating and film sizing. Covers have been suitable only for sizing or coating, but not for both. As a result, lots of applicator rolls and frequent roll changes were needed. Valmet Sizer Roll Cover CF has demonstrated that swing machines can successfully use the same rolls for both sizing and coating.

A roll cover for both film coating and surface sizing, the extremely wear-resistant Valmet Sizer Roll Cover CF gives high-quality coating film formation for easy operation with both smooth and grooved rods.

Blade coating: PU over rubber

Traditionally rubber covers have been applied for blade coater backing rolls. Typically, the process requirements for blade coating are less demanding than for film sizing, with the paper in between cover and coater blade. However, the sensitivity of the coating profile under a very thin blade does require a very good CD profile for the cover, which translates into wear and marking resistance for the cover. Moreover, outside the web at the cover ends, with direct contact between a hard blade and soft cover, the situation is as bad as it can be. Rubber covers become severely scratched and grooved at the cover end, resulting in premature roll changes.

Valmet Coater Roll Cover CC, featuring Valmet PU technology, has once more proven the superiority of Valmet’s material development, giving papermakers significant increases in running time.

The uniform surface and superior wear resistance, especially in the edge areas, allows Valmet Coater Roll Cover CC to significantly extend the operating period and reduce the need for roll changes and regrinding.