Advancing recovery island efficiency and sustainability at the International Chemical Recovery Conference

In late September 2025, over 100 pulp industry professionals gathered in Toronto, Canada to the International Chemical Recovery Conference (ICRC). The event serves as a global platform for industry experts, researchers, and technology providers to advance chemical recovery processes in pulp mills. This event highlights cutting-edge developments aimed at improving efficiency, sustainability, and safety within the chemical recovery cycle.

The program for the three-day event included over fifty presentations running in parallel sessions. Valmet’s was represented in the event with six presentations covering evaporation energy efficiency, recovery boiler reduction optimization, recovery boiler cameras, CDF modelling in recovery boiler combustion diagnostics and carryover prediction and lime kiln fossil fuel replacement. Additionally, Valmet’s evaporation rebuild of CMPC Guaiba mill was highlighted in CMPC’s presentation about the benefits and challenges of 8-effect evaporation plant.

Jarmo Mansikkasalo, Senior Manager for Recovery Boilers at Valmet, worked on several papers for the event. “Together with Matti Selkälä, Business Manager for Pulp Analyzers, we were able to showcase how with different automation solutions and modelling we can improve the recovery boiler performance. With new furnace camera we have excellent image quality and can get a 3D profile which can be used for char bed and carry over management. We have also developed a combustion diagnostics tool utilizing CFD modelling, which provides a visual tool to understand what is happening inside the boiler and with that find optimal combustions parameters or use the tool for troubleshooting. Already earlier we had presented our reduction rate optimization solutions and this time we presented references and showcased the long term results of high reduction rale and stabile operation.”

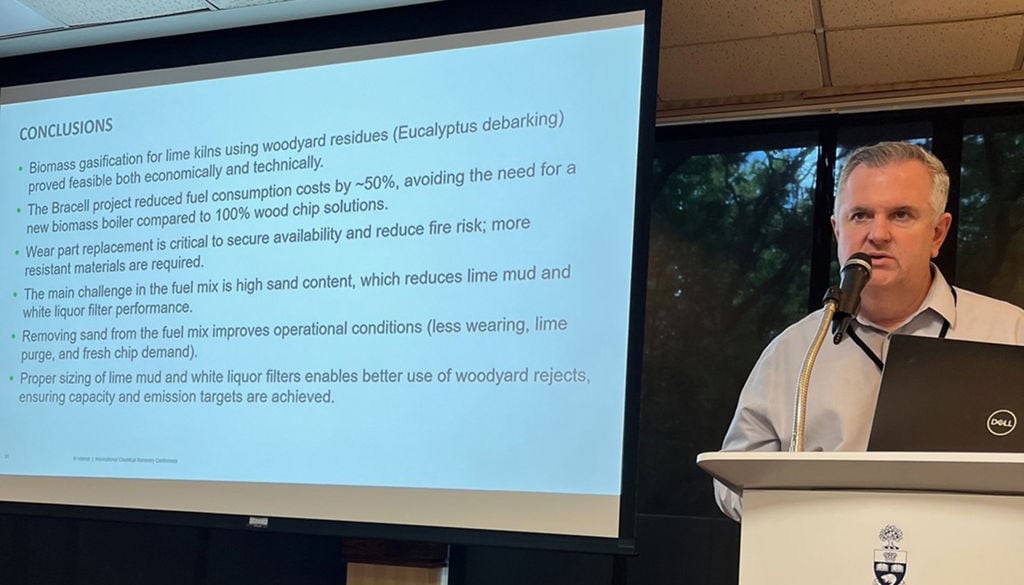

Dimas Rodrigues, Director, Business Development and Engineering, for Valmet Latin America, presented the Bracell mill’s lime kiln biomass gasification case. “Bracell was the first mill in Americas to have lime kiln running with gasified biomass and the first biomass gasification using eucalyptus bark. The presentation candidly covered the challenges of e.g. managing non-process elements, metal and sand impurities in the bark, and mechanical demands, but also how we have been able to manage these challenges. As a conclusion we are able to show that Biomass gasification for lime kilns using woodyard residues proved feasible both economically and technically.”

The event is normally arranged every three years in different locations, and the next event is scheduled to be held in 2028 in Finland.

Related articles