BCTMP line 2 in Phase 2 of Liansheng Zhangzhou Project Successfully Starts Up

Liansheng Pulp & Paper (Zhangzhou) Co., Ltd. announced that bleached chemi-thermomechanical pulp, BCTMP, line 2 in phase 2 of the Liansheng Zhangzhou project was successfully started up on July 11, 2025. The start-up marks another milestone of the integrated forestry-pulp-paper project, which has an annual output of 3.9 million tons and reinforces Liansheng’s flexible raw-material self-sufficiency.

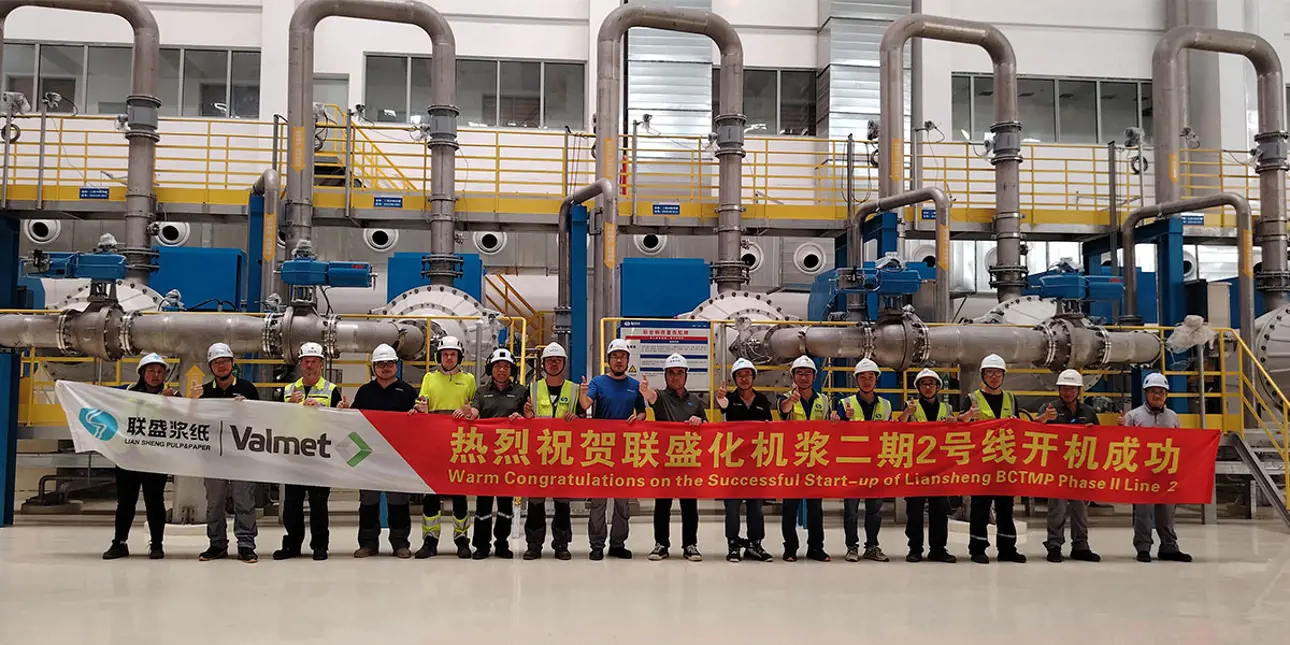

Start-up team photo – Liansheng & Valmet crews

From chip feed to full-line pulp flow, the system was fully commissioned in a little over four hours, with pulp discharge being fed directly to the high-density storage tower. After 20 hours of post-start-up optimization, the primary pulp stream met the furnish specifications of the paper machine, with a brightness of 69–70% and shives below 0.1%. BCTMP from line 2 is now feeding the PM1 coated ivory board machine at the Zhangpu mill.

“I’m delighted that BCTMP line 2 started on schedule. Thanks to both teams for achieving our shared project targets. The new line not only guarantees furnish for the upcoming PM2 start-up but also gives us flexible pulp blending across the site. We look forward to repeating this success on BCTMP line 1,” says Huang Ju, General Manager, Industrial Paper Division, Liansheng Pulp & Paper.

“My sincere thanks to both teams. Valmet’s technical expertise and collaborative spirit were exemplary whenever challenges arose. Rapid coordination and joint troubleshooting during commissioning ensured a smooth start-up and helped to achieve the project’s overall objectives,” says Zhang Bin, BCTMP Senior Manager, Liansheng Pulp & Paper.

“Valmet is honored to partner with Liansheng on another successful delivery at Zhangpu. Together we have installed and commissioned BCTMP line 2. I thank Liansheng for its trust and both teams for their dedication. This marks the first deployment of a Valmet Xi’an Workshop-built TwinRoll press on a BCTMP line. Going forward, we will provide full lifecycle support with faster response and higher efficiency, propelling Liansheng’s integrated forest-pulp-paper vision,” says Yu Weiming, Project Manager, Pulp, Energy & Circularity, Valmet.

Valmet TwinRoll Press at Zhangpu site.

“Once more, our sincere thanks to Liansheng for its steadfast trust. The collaboration during installation, commissioning, and start-up was seamless. Liansheng’s pre-commissioning readiness, flushed systems, and commissioned utilities accelerated our schedule. Both teams’ perseverance and pursuit of excellence delivered a flawless start-up. We look forward to continuing our close cooperation on upcoming projects,” says Li Yong, Site Commissioning Manager, Pulp, Energy & Circularity, Valmet.

First pulp sample from the Conical disc refiner on line 2.

First finished pulp sample from BCTMP line 2.

Technical information about Valmet’s delivery of BCTMP technology

Valmet BCTMP technology is integrated with the coated board line. Valmet’s delivery includes the main equipment for the BCTMP line including the world-leading Valmet Conical Disc Refiner RGP 82 CD and Valmet Conical Refiner Conflo refiners, as well as Valmet TwinRoll Press washing technology. The delivery scope covers engineering, procurement, and site supervision (EPS). Training, site services, and corresponding spare parts are also part of the scope.

Liansheng Pulp & Paper (Zhangzhou) Co., Ltd., established in 2020, is a large-scale integrated forest-pulp-paper enterprise. Its main products include chemical pulp, mechanical pulp, white cardboard, fine paper, and tissue. The Zhangpu site covers an area of more than 300 hectares and has more than 3,000 employees.