Successful Start-Up of BCTMP line 1 in Phase 2 of Liansheng Zhangzhou Project

On September 3, 2025, at 10:20 a.m., Liansheng Paper (Zhangzhou) Co., Ltd. successfully commissioned line 1 of Phase 2 of its bleached chemi-thermomechanical pulp (BCTMP) project. Within just six hours from the initial chip feeding, the entire system was fully integrated and began supplying pulp directly to the coated board production line PM 2 — also delivered by Valmet.

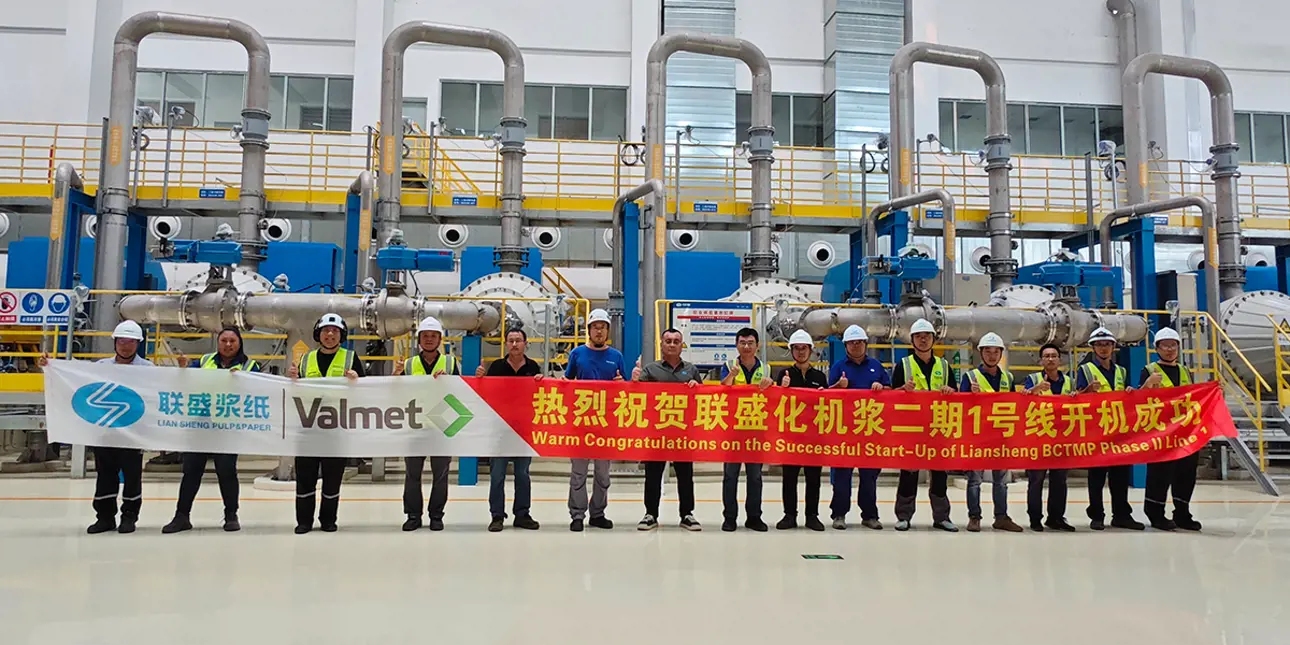

Start-up team photo – Liansheng & Valmet crews.

The pulp quality met all production requirements, achieving a brightness of 70–72% and a shive content below 0.1%. This successful start-up marks a significant milestone for the Zhangpu mill, reinforcing its strategy to achieve pulp-paper balance and demonstrating a strong commitment to enhancing both quality and operational efficiency.

Line 1 features Valmet’s advanced HT-CTMP technology, distinguished by its innovative pressurized impregnation and high-temperature preheating process. This process enhances fiber separation, preserves wood fiber length more effectively, and delivers higher-quality pulp with reduced energy consumption.

Additionally, the production line offers greater flexibility, enabling it to meet a broader range of production requirements aligned with diverse product strategies. As a result, Valmet’s HT-CTMP technology provides robust support for Liansheng Paper’s commitment to high-quality, and sustainable development.

Valmet TwinRoll Presses at Zhangpu site.

"First, I am delighted that Phase 2, Line 1 of the BCTMP-project at Liansheng Paper has been successfully started up. I sincerely thank both teams for their hard work, overcoming many challenges and achieving our common project goals. The successful startup of BCTMP Line 1 together with Line 2, which was started up some time ago, will further strengthen the entire site’s flexible self-sufficiency in pulp supply," says Huang Ju, General Manager, Industrial Paper Division (Liansheng).

"I sincerely appreciate the tireless efforts of both teams! During the project, facing issues and challenges, Valmet leveraged its professional technical strength and efficient collaboration mechanism to smoothly resolve every problem and ensure the overall progress of the project. Line 1 is equipped with Valmet's latest HT-CTMP technology, which is currently running continuously, and has shown great potential to further improve pulp quality and reduce electricity consumption. I believe that the two teams will continue to work hand in hand, strive for perfection, and make Liansheng’s BCTMP production line a new industry benchmark," adds Zhang Bin, BCTMP Senior Manager (Liansheng).

"The successful commissioning and smooth startup of Line 1 fully reflect the high standards and strict requirements that the Liansheng team maintains in project management. Their control of key milestones, efficient and lean operational management, have provided a solid guarantee for the smooth progress of the project. We sincerely thank Liansheng for their trust and support for Valmet," says Yu Weiming, Project Manager, Pulp, Energy & Circularity (Valmet).

Left: First pulp sample from the Conical disc refiner on line 1. Right: First finished pulp sample from BCTMP line 1.

Technical information about Valmet’s delivery of BCTMP technology

Valmet’s delivery includes the main equipment for the HT-CTMP line including chip washing, high-temperature impregnation, pressurized preheating, the world-leading Valmet Conical Disc Refiner RGP 82 CD and Valmet Conical Refiner Conflo refiners, screening and reject refining, as well as Valmet TwinRoll Press washing technology. The delivery scope covers engineering, procurement, and site supervision (EPS). Training, site services, and corresponding spare parts are also part of the scope.

Liansheng Pulp & Paper (Zhangzhou) Co., Ltd., established in 2020, is a large-scale integrated forest-pulp-paper enterprise. Its main products include chemical pulp, mechanical pulp, white cardboard, fine paper, and tissue. The Zhangpu site covers an area of more than 300 hectares and has more than 5,000 employees.

HT-CTMP

Valmet's pressurized preheater and impregnator on line 1 of Liansheng's BCTMP project.