Successful start-up of Sun Paper Nanning chemical pulp production line

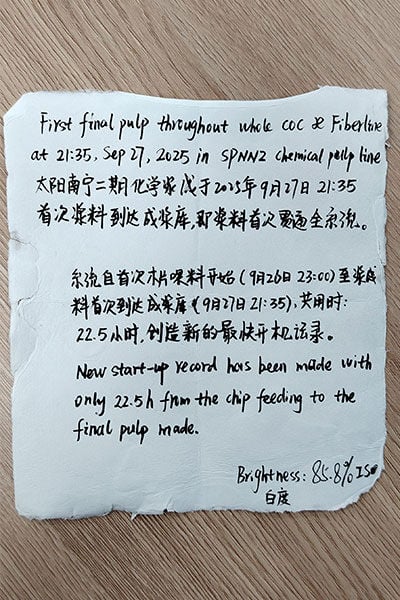

On September 27, Sun Paper (Nanning) Co., Ltd. Announced the successful start-up of its Phase II chemical pulp production line. The process, from initial chip feeding to finished pulp reaching the storage, was completed in just 22.5 hours, achieving a brightness level of 85.8%.

“Congratulations on the successful start-up and production launch of Sun Paper Nanning's Phase II chemical pulp production line! This pulp production line is the third chemical pulp line that Sun Paper has collaborated on with Valmet, following the Sun Paper Laos project and the Beihai project. The newly commissioned chemical pulp production line is particularly equipped with 10 pieces of Valmet TwinRoll presses produced by Valmet's Xi'an workshop. This choice fully meets Sun Paper's high standards for production efficiency and product quality,” says Ying Guangdong, Vice General Manager and Chief Engineer of Shandong Sun Paper.

“The project has achieved a successful start-up ahead of the expected target, thanks to the joint efforts of both parties. I would like to express my sincere gratitude for the hard work of both teams! At the same time, I hope the teams will continue to collaborate after the start-up, further optimize process parameters, and continuously achieve high-efficiency, low-consumption, and high-quality pulp production,” Guangdong continues.

Valmet TwinRoll Press at Sun Paper Nanning site.

“The successful start-up is the result of close collaboration between both teams, as well as the tenacity and perseverance of the Sun Paper team. It also serves as strong evidence of the efficient project management we have in place. Here, I would like to extend my sincere thanks to both teams. It is due to everyone's joint efforts that the project has been able to start up ahead of schedule. The equipment is currently running smoothly, with Valmet’s TwinRoll presses achieving the required pulp consistency. I believe the pulp line will soon reach full production capacity,” says Yan Shiyong, Project Director of Sun Paper (Nanning) Co., Ltd.

“It is with great pleasure that we have witnessed the successful start-up of the chemical pulp production line. From the project preparation to the start-up today, the Sun Paper team has gone through countless days and nights of hard work. Faced with difficulties and challenges, both teams have worked together with one heart and one mind, and with their excellent professional skills, they have overcome each problem one by one. During the project start-up process, whether it is the cooking or the fiber line, all process links have been successfully commissioned at the first attempt, achieving a seamless transition from chip feeding to pulp output,” says Zang Zijia, Deputy Project Director of Sun Paper (Nanning) Co., Ltd.

The TwinRoll presses for the Sun Paper Nanning chemical pulp production line were manufactured at the Valmet Xi’an workshop. The products were delivered ahead of schedule, with high quality and quantity. For the Sun Paper Yandian Pulp Mill project, Valmet Xi’an will again collaborate closely.

The Sun Paper Nanning project demonstrated forward-thinking, professional management, and efficient execution. Valmet aims to continue close cooperation and provide comprehensive lifecycle support to help achieve new milestones in integrated forestry, pulp, and paper operations.

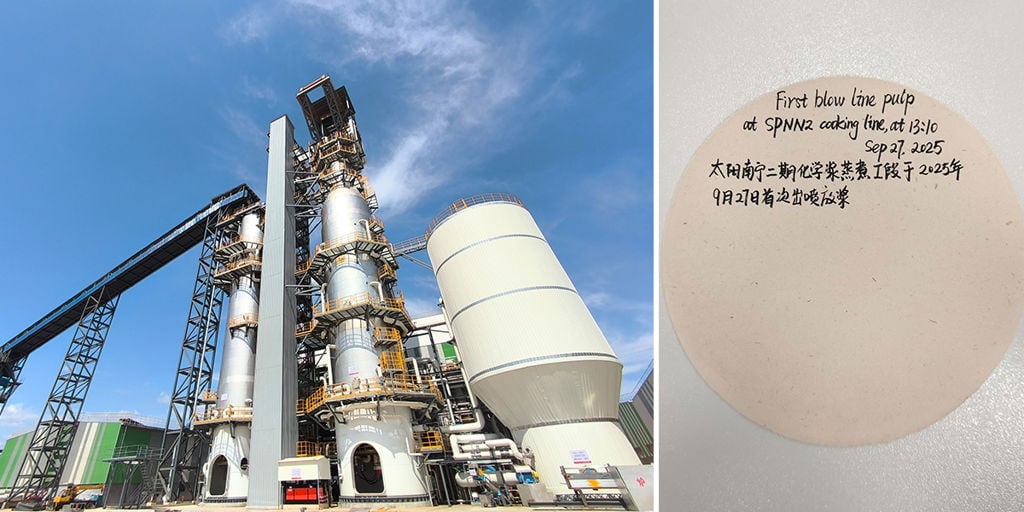

Valmet Continuous Cooking and first blow line pulp at SPNN2 cooking line.

Information about Valmet’s delivery

The scope of Valmet’s supply includes main equipment and process design for continuous cooking, deknotting, screening, brown stock washing, oxygen delignification, and three stage ECF (elementally chlorine free) bleaching. Corresponding spare parts and site services are also a part of the scope.

First final pulp throughout whole cooking and fiberline.

Information about Sun Paper Nanning

Nanning Sun Paper Co., Ltd. is a wholly-owned subsidiary of Shandong Sun Paper Industry Co., Ltd. and was established on February 10, 2022. As an important strategic layout of Sun Paper in Guangxi, it is an integral part of Sun Paper's "433" medium- and long-term development strategy, aiming to further enhance the company's competitiveness in the integrated forestry, pulp, and paper industry chain.