Superior test liner quality through dilution control: Ajin P&P’s formula for success

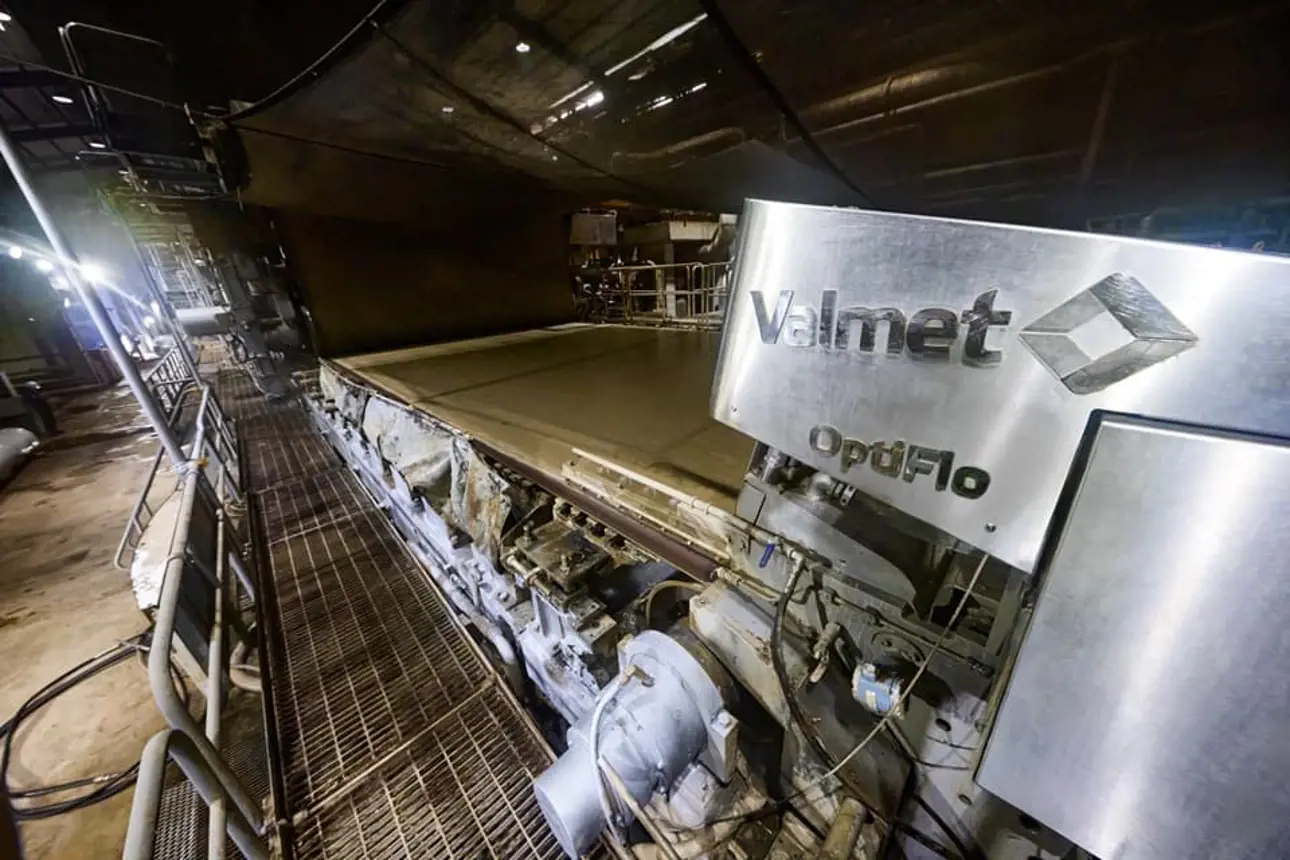

Ajin P&P Co., Ltd. is a Korean corrugated board and packaging manufacturer that highly values the importance of R&D and sustainability and wants to be the leader in recycling business. As a part of long-standing development program aiming to improve quality, they invested in a new OptiFlo Fourdrinier headbox with Valmet IQ Dilution Profiler for their BM 2.

The best dilution control

Dr. Jin-Doo Kim, CEO, Ajin has been working in the paper industry for four decades. During this time, he invested in 13 headboxes from Valmet. When asked why always choosing Valmet, the answer is simple.

“There are two choices when it comes to headboxes. You can choose a cheaper headbox with quite OK technology and reach decent quality. Or you can choose a dilution control headbox and automation from Valmet and guarantee superior quality, consistently,” Dr. Kim states.

He continues by explaining that the Valmet IQ Dilution Profiler in OptiFlo headboxes is the key. When combining the proven headbox technology with Machine Controls, Distributed Control System, and Quality Control System from Valmet, you can ensure such an overall performance and quality that no other technology supplier can match. This enables Ajin to provide their customers with a totally different level of service and quality.

Dr. Kim concludes by stating, that “If I ever have a chance to invest in a new headbox again, it will be from Valmet.”

BM 2 produces 115 to 250 g/m² test liner grades from Korean OCC (Old Corrugated Container). The back ply headbox was upgraded to OptiFlo Fourdrinier headbox in August 2023.

Long-term investment plan

For a small sized board manufacturing company like Ajin, it is not possible to execute massive machine line rebuilds and upgrades as one big project, Dr. Kim clarifies, but they must be done step by step over several years or even a decade.

“Our philosophy is that every single day we think that how can we improve to serve our customers better. Truly, we discuss this every single day. Then we execute these changes gradually, step by step. It is hard work but after 10 years and several upgrades and improvements in our process and machine line, we have accumulated substantial competitive advantage and can now provide the best quality test liner on the Korean market. The new headbox is crucial in achieving this,” Dr. Kim confirms.

Text: Elsa Sinjaga

Further reading on OptiFlo Fourdrinier headboxes