Visible thermal imaging system enhances sugarcane boiler control at COFCO in Brazil

In early 2025, Valmet delivered its first visible thermal camera for a plant in the sugarcane industry, marking the company’s first camera delivery in the energy sector in South America. The system was installed at COFCO International’s facility in Brazil to monitor the boiler’s bed and provide real-time flame information. The new system enables more stable combustion and efficient startups, while reducing maintenance effort thanks to automatic cleaning and built-in protection.

From the left: Application Technician Alan Trinck from Valmet with satisfied customers enjoying the fully installed visible thermal camera system.

COFCO International is China’s largest food and agriculture company. With operations spanning 36 countries and employing more than 11,000, COFCO plays a central role in global agribusiness. In Brazil, its extensive sugar cane processing facility in Catanduva in the São Paulo state uses a bubbling fluidized bed (BFB) boiler that generates approximately 350 tons of steam per hour. All byproducts not used for ethanol production are burned in the boiler to produce energy.

Residues from sugarcane processing are used as fuel at COFCO International’s BFB boiler in Brazil, where Valmet’s visible thermal imaging system supports stable and efficient combustion.

COFCO already had an established relationship with Valmet’s flow control products, so when it came time to choose a camera provider for its new power boiler, Valmet was the natural choice. The company was also familiar with Valmet’s proven solutions in the Brazilian pulp and paper sector.

Real-time monitoring for better boiler control

COFCO was looking for a simple yet robust visible-light camera that could withstand the high temperatures associated with biomass combustion while providing high-quality and clear real-time visual feedback during boiler startup. The startup process, which occurs a few times each year, is critical for stable boiler operations.

To maintain stable combustion, operators also need a reliable way to monitor flame formation, fuel distribution and bed conditions inside the boiler. “These capabilities are exactly why our customers choose and value these visible thermal cameras,” says Jesús Nuncira Valencia, Product Manager, Boiler Diagnostics Systems at Valmet.

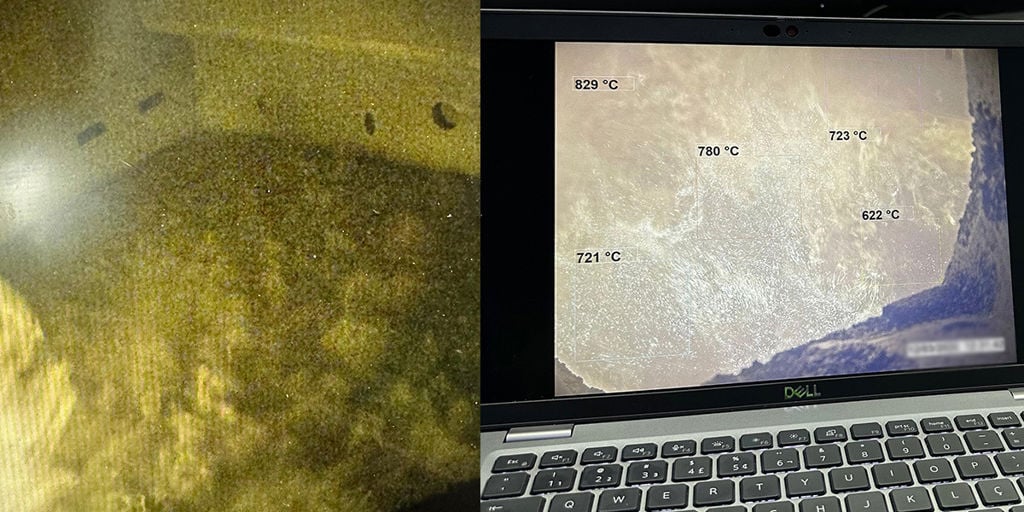

Picture on the left shows the bed condition and fluidization of the BFB boiler. Picture on the right displays the full-screen mode of the Visible Thermal Viewer in the control room. Five temperature areas have been defined, with their values also visible in full-screen mode.

Custom angle provides full bed view

Cost-effectiveness was a key factor for COFCO’s decision to proceed. Valmet provided a visible-thermal imaging solution that not only provides a clear visual of the bed but also includes temperature data. This added capability enables deeper process insight and operational flexibility demonstrating our commitment to exceeding customer expectations.

The installation came with its own engineering challenges. The inclination angle chosen for the camera in the corner of the boiler was unusually steep, and ensuring a full view of the bed area required precise calibration.

Thanks to the expertise of Valmet’s design team, we achieved over 80% of the bed area with just one camera.”

“Initially, we could only get a view of 50% of the bed. However, thanks to the expertise of Valmet’s design team, we achieved over 80% of the bed area with just one camera,” says Alan Trinck, Application Technician at Valmet in Brazil. “The steep angle ultimately provided a much better view.”

Built-in protection, easy integration, minimal maintenance

Additionally, the camera featured an automatic retraction system to prevent camera damage in case of insufficient air supply or power. “If the compressed air supply fails, the system automatically retracts the camera from the boiler” says Nuncira Valencia.

If the compressed air supply fails, the system automatically retracts the camera from the boiler.”

The hardware was seamlessly integrated into the facility’s existing network. “Operators can access live visuals of the boiler directly from a laptop using the Real-Time Streaming Protocol (RTSP), enabling real-time monitoring,” he adds.

Valmet’s Application Technician Alan Trinck monitors the fluidization of the bed via an RTSP stream. The visible thermal camera system includes a control cabinet, air filters, a retractable camera, and a PC displaying live camera visuals.

One positive aspect of the new camera is its automatic cleaning. It doesn’t require any human intervention, so we don’t need to spend time on upkeep - just routine visual inspection.”

“One positive aspect of the new camera is its automatic cleaning. It doesn’t require any human intervention, so we don’t need to spend time on upkeep - just routine visual inspection,” says José Nacci Junior, Project Coordinator at COFCO.

Image quality exceeds expectations

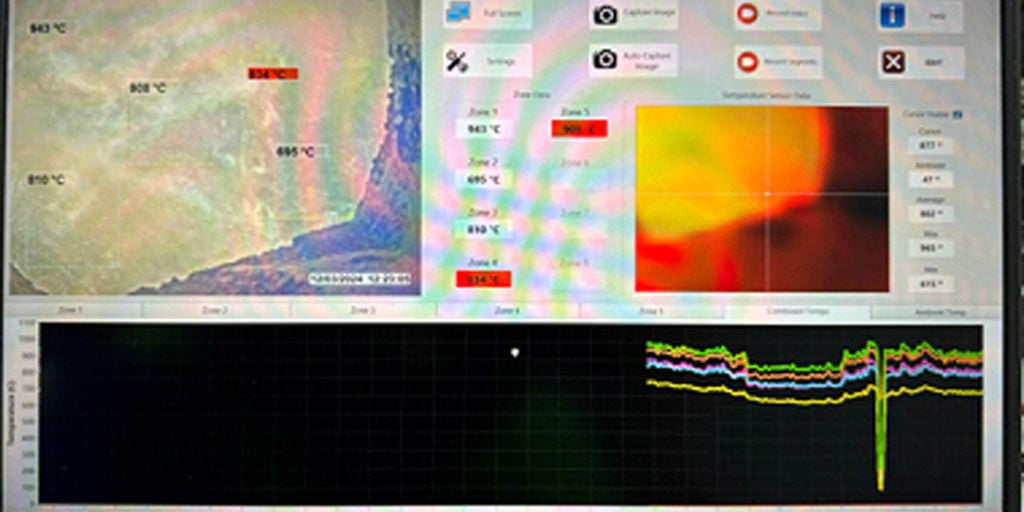

The camera’s robust digital image and thermal sensing quality exceeded customer expectations. It clearly displays flame patterns and temperature distribution in any selected area.

One of the goals was to ensure that combustion is homogeneous – not just at startup but also during daily operation. This objective was achieved and significantly helps operations. Based on the camera images, we can identify airflow preferences and signs of inhomogeneous combustion. Then, we can control the process in real-time to make it more stable.”

Visible Thermal Viewer software showing high-definition process image, thermal profile, and temperature trends over time.

“One of the goals was to ensure that combustion is homogeneous – not just at startup but also during daily operation,” says Nacci Junior. “This objective was achieved and significantly helps operations. Based on the camera images, we can identify airflow preferences and signs of inhomogeneous combustion. Then, we can control the process in real-time to make it more stable.”

COFCO also reported a smoother startup process and greater operator confidence.

Delivering what was promised

Commissioning of the camera was completed in early 2025. Project communication was outstanding right from the start. “This approach helped us meet the tight delivery timeline. We also made sure our offer was clear and detailed,” Nuncira Valencia says. “We delivered what we promised – on time.”

We also made sure our offer was clear and detailed. We delivered what we promised – on time.”

From the very beginning, Valmet provided us with full support. The technical assistance – from sales through installation – was excellent. But the biggest highlight has been their after-sales service, which responded to every one of our requests.”

“From the very beginning, Valmet provided us with full support. The technical assistance – from sales through installation – was excellent. But the biggest highlight has been their after-sales service, which responded to every one of our requests,” says Nacci Junior.

Both the operational and maintenance teams received theoretical and practical training with all necessary precautions clearly explained.”

Alan Trinck also worked closely during installation and provided technical training to COFCO personnel. “Both the operational and maintenance teams received theoretical and practical training with all necessary precautions clearly explained,” says Nacci Junior.

We would definitely consider partnering with Valmet again because their product fully met our needs.”

“We would definitely consider partnering with Valmet again because their product fully met our needs,” Nacci Junior concludes.

Alan Trinck from Valmet (on the left) with happy customers, celebrating a successful project.

Milestone success

According to Nuncira Valencia, this project highlights Valmet’s growing capability to deliver customized solutions in the biomass sector and as well as in industries like sugarcane processing - a major industry in Brazil and across South America.

With proven performance, a satisfied customer and strong regional presence, Valmet is well positioned to help other customers take advantage of its advanced solutions.

For further information on the topic, Adriano and Jesús will be happy to help you:

Adriano Teixeira, Sales Manager, Valmet Brazil

adriano.teixeira(at)valmet.com, tel. +55 15 99634-9357

Jesús Nuncira Valencia, Product Manager, Boiler Diagnostics Systems jesus.nunciravalencia(at)valmet.com, tel. +358 50 330 2869