OptiRun Single - compact and efficient dryer section geometry for single-fabric applications

Aug 6, 2014

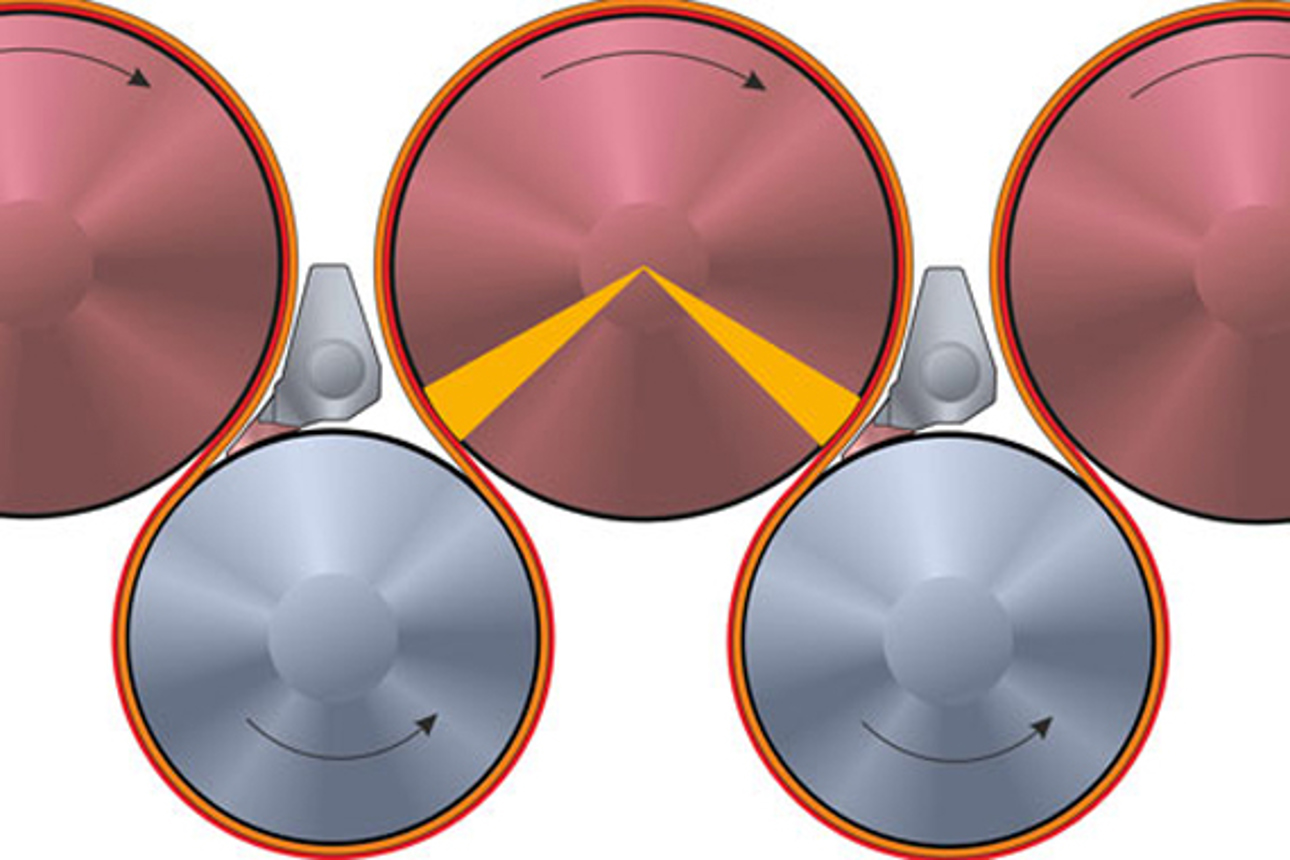

The compact OptiRun Single has an increased wrap angle of the web on the cylinder surface as compared to the conventional dryer section, thus increasing drying capacity.

Valmet has developed a new, compact OptiRun Single dryer section geometry for single-fabric applications. This solution combines excellent runnability with low energy and maintenance costs.

The new OptiRun Single with compact geometry is part of Valmet’s OptiRun dryer section family. The idea behind this solution is to simplify the design by minimizing the gaps between dryer cylinders and rolls, and by reducing the number of blowers and air ducts, while still ensuring excellent runnability and fluent tail threading. Thanks to the compact design, the wrap angle of the web on the cylinder surface is increased, thus increasing the drying capacity. The minimized gaps contribute to less wear on the dryer fabrics and sealings because there is less unwanted fabric bending.

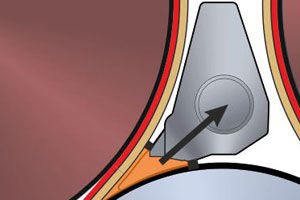

The compact geometry provides very high vacuum (the underpressure on the pocket when the web is on up to -2 kPa compared with the conventional -0.3 kPa) on the whole pocket, including the closing nip of the bottom roll. The vacuum is created by suction only, compared with the suction and blowing technology used in conventional blow boxes. This contributes to lower energy consumption.

|

Underpressure in the opening nip is created by suction. The compact single-fabric geometry provides very high vacuum on the whole pocket, including the closing nip of the bottom roll. |

The compact OptiRun Single solution is best applicable to fine paper and liner and fluting board grades, and machine widths up to 8 meters. The speed range is 1,000 – 1,600 m/min. At lower machine speeds the bottom roll can be a UnoRoll without a vacuum blower. As the speed increases to more than 1,200 m/min, Edge VacRolls can be used to facilitate tail threading and web edge behavior. At speeds of more than 1,400 m/min, VacRolls can be used to ensure maximum runnability. The freely adjustable vacuum levels mean that it is easily operated and there are optimal vacuum levels in all conditions.

The compact OptiRun Single solution is suitable for both new machines and rebuild installations. Proven with two recent references, runnability and tail threading are excellent. When using open fabrics and/or UnoRolls, cleanliness is improved and the overall energy and maintenance costs are lower compared with conventional systems. With this new innovative dryer design, Valmet’s OptiRun dryer section product portfolio is able to provide perfect solutions for all market needs.

Good results at Fujian Liansheng

The Fujian Liansheng PM 6 containerboard machine in China features OptiRun Single with compact geometry in the 7th dryer group.

“The dryer section’s runnability and tail threading have performed perfectly. In this section we almost never see any breaks or stuck doctors. We have even tested running without paper guiding blows, and still the web runs through smoothly. I think this geometry has quite unique advantages", says Xue Run Jung, Project Manager, Fujian Liansheng.