Maximizing your water efficiency

Water efficiency solutions for board and paper

Want to reduce your environmental footprint?

Our experts can support you to find the most suitable solutions for your sustainability needs.

Contact our expertsConsume less freshwater for lower environmental load

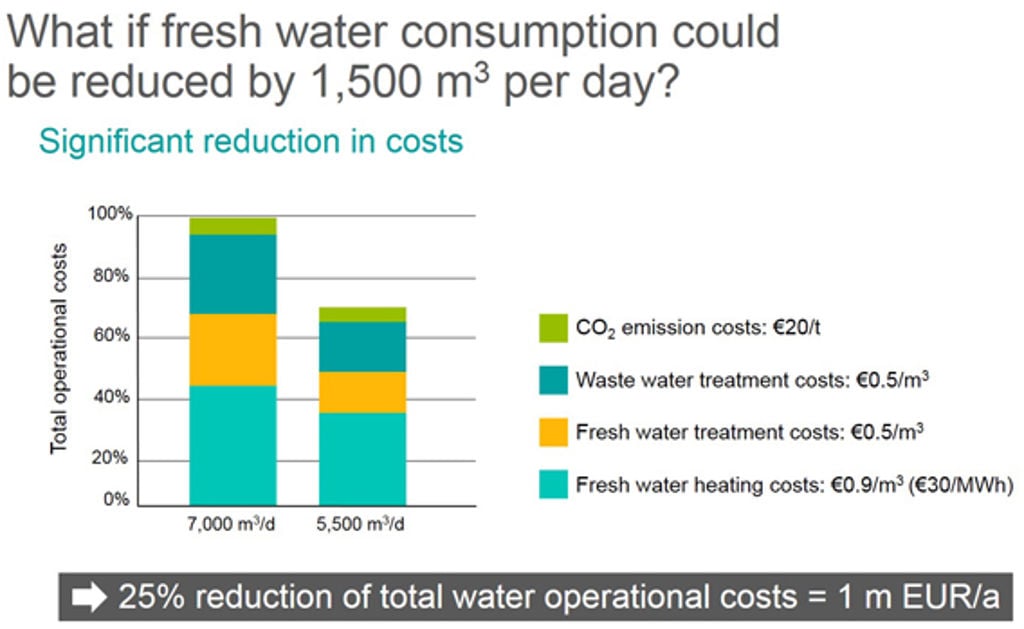

Fresh water is one of the most critical resources for pulp and paper mills today. By consuming less fresh water, paper mills can influence both the quantity and quality of their environmental load. For example, toxic pollution emissions to water systems decrease, along with the unnecessary use of chemicals, less carbon dioxide is released by the heating of freshwater, and the overall energy consumption is reduced, as are wastewater and solid waste volumes. The optimization of freshwater consumption and raw materials usage will enable mills to better meet ever-tightening environmental requirements.

From a process point of view, proper water management is needed to ensure good runnability at low freshwater consumption levels. With efficient water management, pulp and paper mills are able to achieve big measurable savings and improve their total efficiency.

Comprehensive solutions for better water utilization

Valmet’s comprehensive water management solutions include process optimization, process evaluation and feasibility studies, and water concepts for lowering freshwater consumption in the production of various paper grades. We also offer advanced water treatment processes based on Valmet Ultrafilter CR (=cross rotational) ultrafiltration technology.

- Valmet Ultrafiltration W for paper machines' white water treatment to reduce freshwater consumption

- OptiCycle R to remove resins from mechanical pulp mill filtrates

- Valmet Ultrafiltration C to recover coating color from effluent

- OptiMixer Stock and OptiMixer Retention mixers for the efficient mixing of chemicals and pulp

Explore our latest board and paper press releases

- Jan 29, 2026Valmet launches new Bioneer press roll covers with reduced climate impact

- Dec 19, 2025Muoto products produced with Valmet 3D Fiber technology piloted at Valmet’s Jyväskylä location

- Dec 8, 2025Valmet has completed change negotiations for temporary layoffs in the Packaging and Paper business area and Global Supply unit in Finland

- Nov 26, 2025Valmet supports Wuzhou Special Paper’s transition to recycled board grades with a complete paper machine conversion rebuild

- Nov 5, 2025Valmet to start change negotiations regarding temporary layoffs in the Packaging and Paper business area and Global Supply unit in Finland

- Sep 16, 2025Valmet strengthens customer value by delivering a high-end sack and kraft paper machine for Guangxi Jianhui Paper in China

- Aug 21, 2025Valmet to supply two papermaking lines to a customer in China

- Aug 18, 2025Successful start-up of Sappi North America’s rebuilt board machine PM 2

- Aug 13, 2025Valmet launches next-generation Valmet Conical Refiner Conflo L model, designed for higher capacity and efficiency

- Aug 7, 2025Successful start-up at Liansheng Pulp & Paper’s coated board making line PM 2