Infrared camera for combustion process visualization and decision-making

Valmet Furnace Infrared Imaging System

The Valmet Furnace Infrared Imaging System (Valmet FIRIS) continuously monitors high-temperature combustion processes in any type of boilers and combustion units. Its unique infrared technology enables visibility through dust, gas and other particles at distances of up to 25 meters. With fully digital and uncompressed imaging, Valmet FIRIS camera ensures high-fidelity imaging of the combustion process, enabling advanced image processing applications such as precise bed height and bed volume measurement.

Automated safety actions with real-time visual feedback on power, airflow, temperature, pressure, and system status

Clear insight into critical boiler conditions: char bed, burners and boiler wall tubes

Complete software application suite including the new Recovery Boiler Bed Profile

Infrared imaging for extreme conditions

The Valmet Furnace Infrared Imaging System (Valmet FIRIS) delivers real-time data to identify problems and take corrective actions. Designed for extreme environments, the Valmet FIRIS camera can see through flue gas and fly ash at temperatures ranging from 370°C to 1900°C. Its high-quality, deep-view infrared imaging enables comprehensive observation and analysis under full load, reducing risks and enhancing productivity.

The camera supports visual monitoring inside furnace environments, providing crucial information about slag buildup, burner operation, flame position, and heat exchanger tube plugging. This information helps improve heat transfer efficiency, lower maintenance costs, and contribute to higher availability.

Engineered for durability and longevity, the system is ideal for high-temperature industrial processes. In pulp and paper recovery and power boilers, it assists in observing bed conditions, water leaks, liquor-spray patterns, and sootblower operation. For Ladle Metallurgy Furnaces, a specialized configuration provides an unobstructed view of the entire tapping process, enabling safer and more efficient operations.

Fixed and mobile inspection solutions

The Fixed mount installation can consist of a single camera or an array of cameras to provide full coverage of the combustion environment. A fixed installation includes the infrared camera, an air-cooled electrical enclosure, straight lens tubes of varying lengths and viewing angles, and optionally, an automatic retractor for lens protection and a port rodder for cleaning.

The Portable inspection camera kit contains everything needed to inspect a boiler from any accessible port. Housed in a single wheeled case, the mobility kit includes an air filter and connection hose, rechargeable batteries with charger, and a heat shield to protect the user. The kit can be used for internal boiler inspections as well as for checking the shell or electrical equipment.

Advanced analysis with purpose-built software

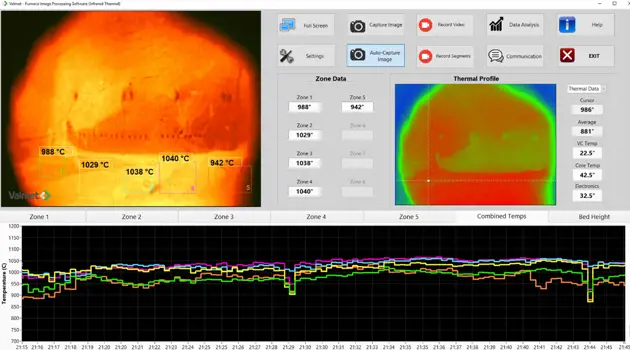

The Valmet Furnace Image Processing Suite takes visual and temperature data to a whole new level of insight and value. The Valmet Basic Viewer provides a simple, intuitive interface for viewing and recording digital video streams. With tools for image colorization, time and label overlays, and the ability to draw and mark on live images, the software delivers a powerful set of features for effective monitoring and analysis.

The Reporting and Analytics application gives operators unparalleled insight into their process data. For example, an entire day of operation can be compressed into a short, easy-to-review video with key performance metrics, making it simple to understand and evaluate daily events. Reports can also be generated and distributed automatically, supporting faster decision-making.

Valmet Slag Indexing application measures slag build-up on furnace walls or heat transfer surfaces. The measured information can be utilized to improve boiler cleaning and sootblowing. Valmet Slag Indexing helps to minimize super heater plugging and maintain optimal heat transfer efficiency, leading to improved boiler performance and reduced maintenance costs.

Thermal data with visual inspection

In addition to delivering clear visual images, the Valmet Furnace Infrared Imaging System can be equipped with a through-the-lens pyrometer for precise surface temperature measurement. This option enables temperature readings from 530°C to 1600°C, allowing operators to combine visual and thermal insights for a deeper understanding of furnace performance. By integrating advanced analysis of temperature and imaging data, operators can accurately assess various operational features and conditions.

With the thermal configuration, the system includes the Infrared Thermal Viewer software application, providing advanced, fully integrated imaging and temperature measurement capabilities for critical boiler areas. Real-time temperature readings enable more efficient monitoring and control of superheated zones, waterwall conditions, and bed temperatures, improving overall process efficiency and reliability.

Advanced recovery boiler solutions

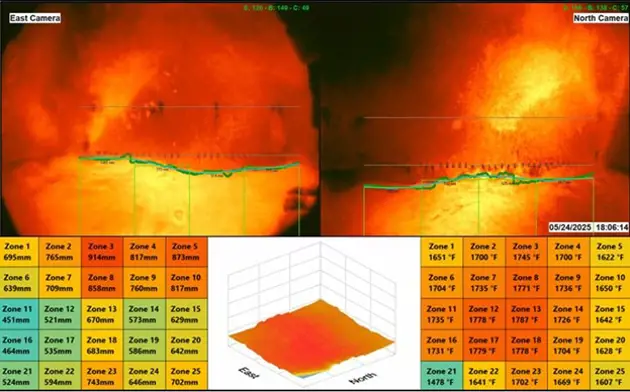

Advancements in the Valmet Furnace Infrared Imaging System (Valmet FIRIS) have enabled the development of our latest software innovation — the Valmet Recovery Boiler Bed Profile. This application provides real-time mapping of the recovery boiler smelt bed, utilizing two Valmet FIRIS cameras to accurately measure bed temperature and height.

When integrated with the Valmet Recovery Boiler Optimizer, the solution enhances overall boiler performance by improving reduction efficiency, reducing SO₂ emissions, and increasing operational safety.

|

Pulp mill recovery benefits |

Power utility benefits |

Metallurgy benefits |

|

|

|

Discover how Valmet FIRIS can enhance your boiler performance

Get in touch with our experts to arrange a detailed presentation or an inspection trial tailored to your needs.

Contact us