Valmet launches next-generation Valmet Conical Refiner Conflo L model, designed for higher capacity and efficiency

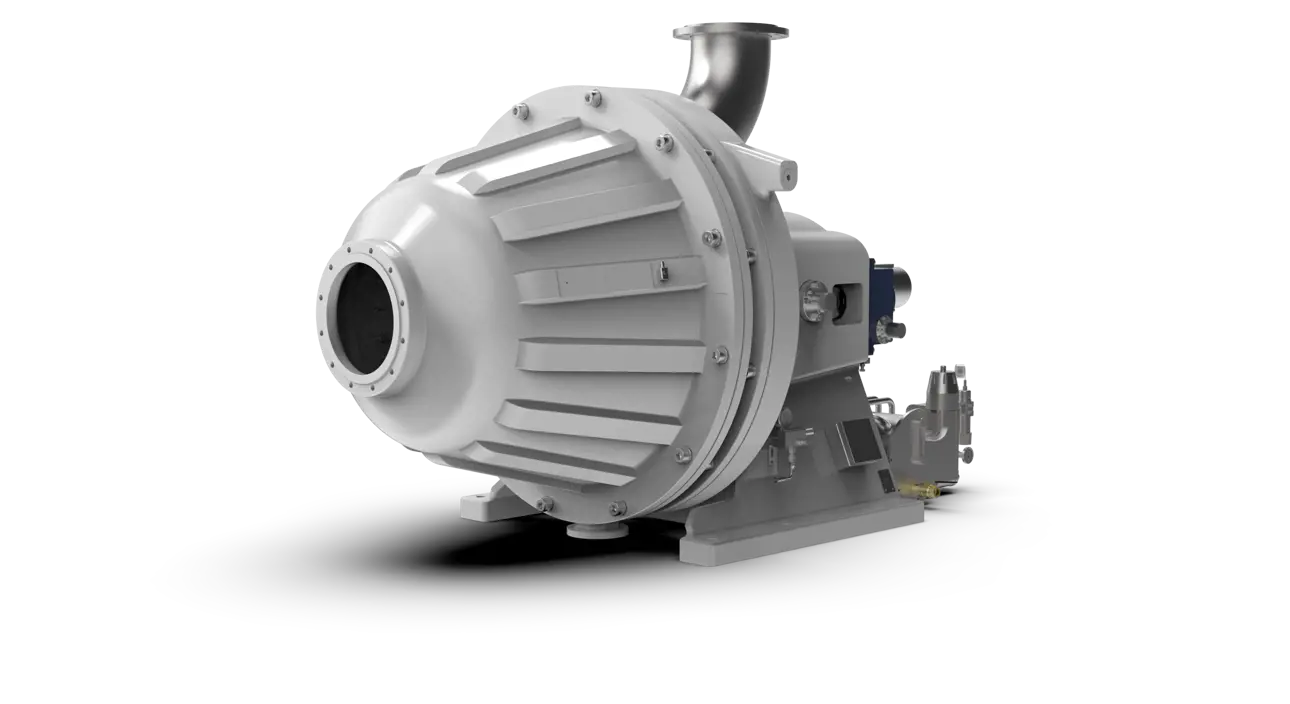

Valmet is proud to announce the launch of the Valmet Conical Refiner Conflo L model, the next generation of its proven conical refiner family.

Developed in response to growing performance demands in mechanical pulping and fiber refining, the Valmet Conical Refiner Conflo L model introduces a new benchmark in capacity, durability, and process efficiency.

With up to 30 percent more refining capacity, improved motor load utilization, and enhanced wear resistance, the L model supports higher throughput and better fiber development, particularly in demanding applications such as BCTMP, MFC, and hardwood refining.

“Valmet Conical Refiner Conflo L represents a significant improvement in the refiner design,” says Marko Loijas, Senior Manager, Refining from Valmet. “We’ve focused on increasing the active surface area and cutting length to enable more efficient energy use and extended consumables life. The result is more tonnes processed with fewer refiners, lower operating costs, and more stable production.”

The Valmet Conical Refiner Conflo L model is available in sizes 1 through 5, covering both high-capacity fiber lines and specialty applications such as decor paper, where improved refiner segment durability provides a clear operational benefit.

As part of the launch, Valmet also offers a rebuild solution that allows existing Valmet Conical Refiner Conflo units to be upgraded to L model performance with minimal modification. The upgrade kit provides a cost-effective path to modernizing installed equipment and increasing line capacity.

The Valmet Conical Refiner Conflo L series is now available globally, with a clear focus on capacity, efficiency, and long-term reliability.

For further information, please contact:

Marko Loijas, Senior Manager, Refining, Packaging and Paper Business Area, Valmet, tel. +358 400 884 114