Tested & Proven 2/3: Type tested and independently approved

In this second blog of the Tested & Proven -series, we look at the type testing required for the valve technologies our customers have placed orders on. Every customer has their individual needs and specifications. Our quality standards are set to ensure we can deliver on expectations.

Quality must be comparable

Standardized validation and type approvals are often the best way to provide unbiased assurance of quality and reliability. Testing data and outcomes become easier to interpret and compare when common methodologies and criteria are established. By providing type testing for ordered valves we are able to give peace-of-mind to the customer.

Demand for tested performance

Valves bought by customers often require type approvals for performance factors such as emissions, fire-safety and flow characteristics. These tests are performed according to international standards and witnessed by an accredited 3rd party inspection body. Important factors affecting valve purchase decisions typically include safety and sustainability factors in addition to efficiency and financial performance over a valve’s full lifecycle.

For this exact reason we often run extended high-cycle testing on valves. In some cases, it may consist of a period of several years and millions of cycles. Type testing for fugitive emissions may last as long as six weeks and consist of 100,000 cycles. Our valves need to be solid and reliable throughout their entire lifecycle and meet even the strictest requirements.

Flow coefficient measurements enable accurate and reliable valve selection with Nelprof™ sizing and selection software

Understanding customer requirements

Understanding the processes and requirements of our customers, helps us understand and set realistic targets for our product development. Testing our products against the most demanding and harsh process conditions proves their superiority. Decades of experience comes in handy, when selecting a valves partner that can help you reach your targets in reliable and smartest way possible.

Ambitious quality system in place

We at Valmet have a very stringent quality system in place internally. The quality requirements extend to all aspects of research and product development testing. We often set a standard for testing equipment that is beyond that of the manufacturer. The measurement equipment are maintained and calibrated regularly.

High-standard testing facilities

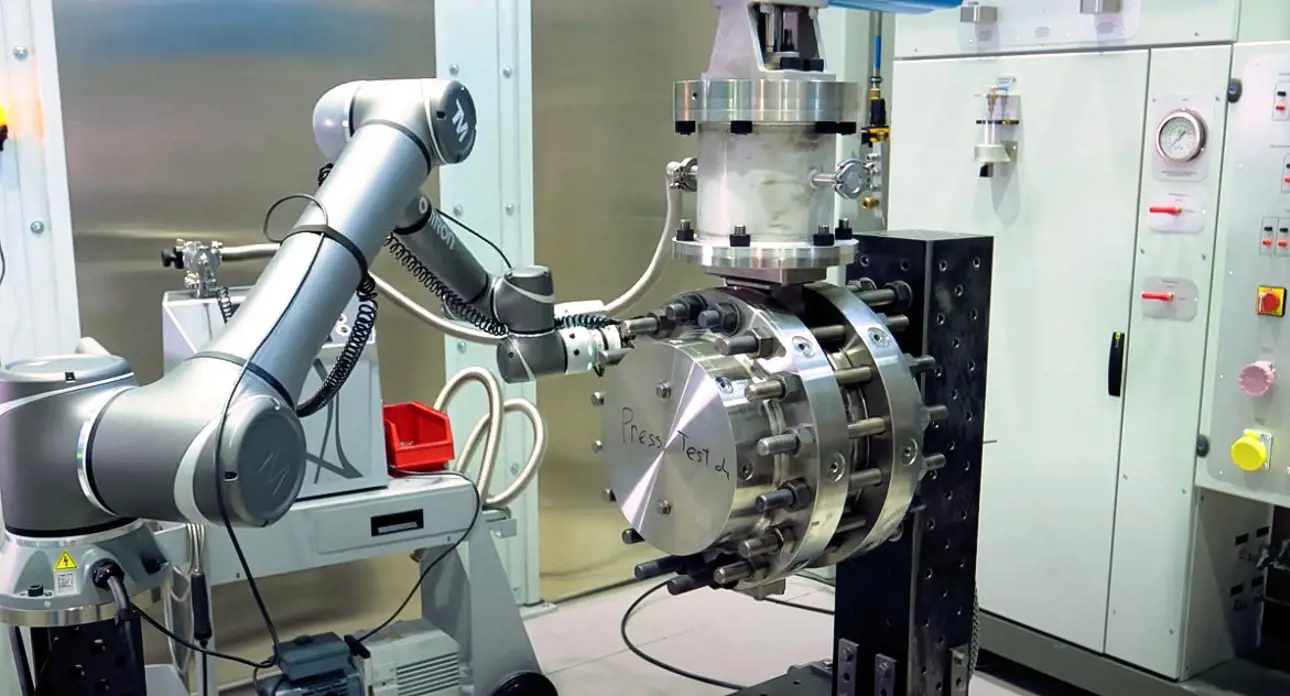

We take great pride in the quality and safety of our labs and testing facilities. Typically, all doubts are erased when the customer enters our labs. We have safe enclosures for all high-pressure gas testing and regularly utilize robotics to carry out fugitive emission testing procedures with no risk to testing personnel.

Value through experience and insight

As is the case with everything in life, in valve technologies too, experience brings perspective and value. Machines may do the physical work in terms of testing, but the knowledge and insight lies in the people running the testing. The majority of personnel at all our testing facilities on three continents have at least a decade or two of experience, meaning that each of our valves benefits from hundreds of years’ worth of accumulated flow control experience.

More on the topic of testing

Don’t forget to read the first blog in this series to find out a little more about the testing carried out on potential new technologies and components before they ever become a part of a valve that is tested in the ways described in this text. Also, stay tuned for an exciting look at the quality control testing we carry out on valves assembled at our facilities for sale and delivery.