Beyond Circularity: Advancing hard metal recycling

Valmet is proud to be part of the Caramel project consortium, which aims to develop circular processes and sustainable applications for novel hard metal coatings and structures. This project is a part of Valmet’s Beyond Circularity R&D program and ecosystem.

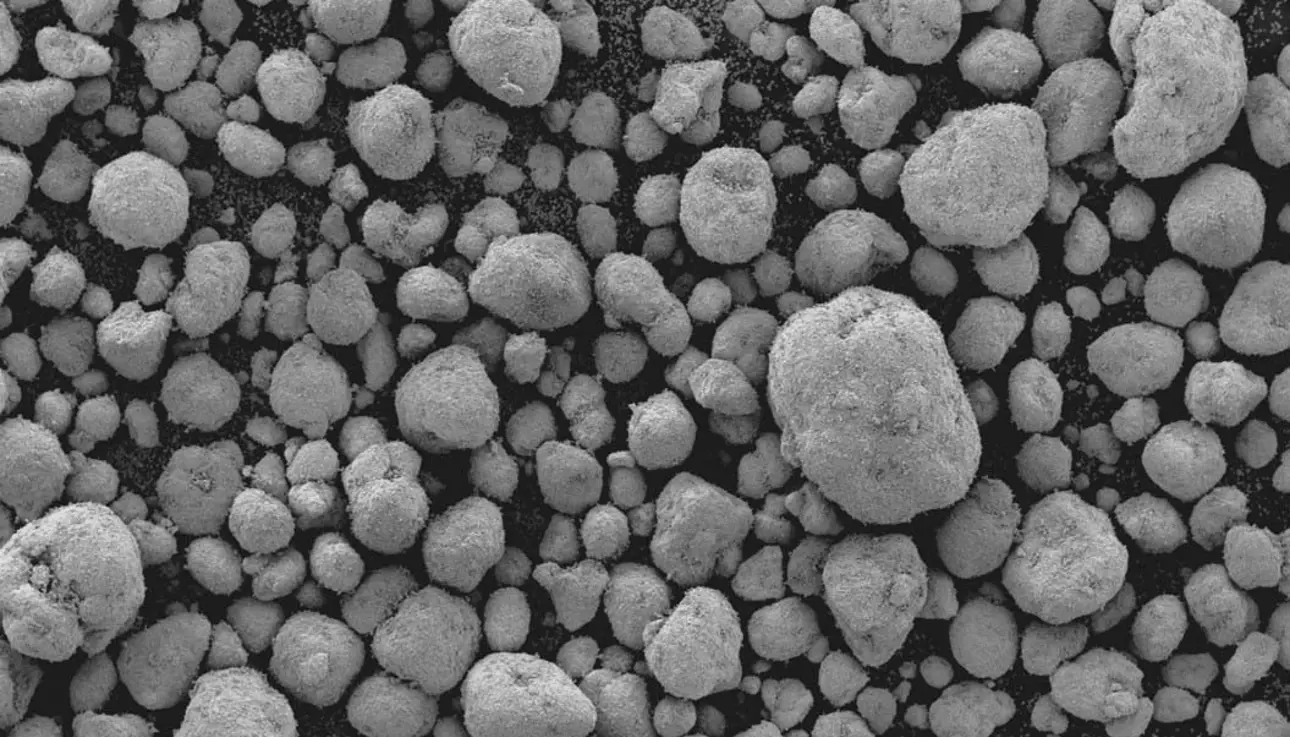

Image: Ready to press powders production was studied with high shear mixer and spray drying in air with water suspensions.

Hard metals i.e. cemented carbides, which typically consist of tungsten carbide (WC) and cobalt, are essential in applications that demand extreme durability. However, their high carbon footprint and critical raw material status in the EU have increased the demand for recycling. Enhancing recycling processes reduces environmental impact and strengthens raw material supply security.

Hard coatings, also consisting of tungsten carbide and cobalt, are crucial in enabling modern board, paper, and tissue machines to operate continuously with high production efficiency while minimizing material and energy consumption. They are used for wear and corrosion protection in paper roll covers, paper process parts, and other spare parts. Currently, most tungsten carbide comes from virgin raw materials, contributing to a high carbon footprint.

Paper machine roll with a hard coating

Valmet is one of the biggest users of tungsten carbide (WC) -based materials in thermal spraying in Finland, so we are excited to be part of the Caramel project aiming to develop the recycling of tungsten carbide and cobalt. This will also support Valmet’s ambitious target to enable 100% carbon neutral production for all Valmet’s pulp and paper customers by 2030,” says Olli Etelätalo, R&D Engineer at Valmet’s Tissue business area.

The Caramel project was launched in September 2023 and is scheduled for completion by December 2025. The consortium is led by VTT Technical Research Centre of Finland and Tampere University, with participants from various parts of value chain like Valmet, tungsten carbide powder manufacturer Oerlikon Metco, tungsten carbide recycler Tikomet, and tire stud manufacturer Tikka Spikes

Promising results from LCA and spray testing

Veera Marttila from VTT Technical Research Centre of Finland has conducted a Life Cycle Assessment (LCA) comparing the environmental impact of recycled versus traditionally manufactured tungsten carbide and cobalt. The LCA results show that recycling tungsten carbide and cobalt via the zinc process significantly reduces environmental impact across all categories in both Chinese and North American scenarios. Favoring recycled materials over primary mining reduces the overall environmental footprint. Additionally, the study confirms that the direct zinc recycling process is highly energy-efficient compared to primary raw material production.

Climate change impact for 1kg of powder

Cumulative energy demand for 1kg of powder

Increasing the recycling rate would also support the EU’s Critical Raw Materials Act, which aims to boost recycling for key materials like tungsten and cobalt. Recycling is essential for securing the supply of these critical raw materials, which are vital for the green transition and the EU's future economic development.

Additionally, both Tampere University and Valmet in Jyväskylä have successfully sprayed and analyzed test powders, and the coatings produced from them. Based on these tests, thermally sprayed coatings from recycled tungsten carbide powders can produce coatings of comparable quality to coatings produced from virgin raw materials when other powder properties are matched.

References:

V. Marttila, P.Kivikytö-Reponen, J.Lagerbom, J. Ronkainen, T. Karhumaa, T. Varis, E. Huttunen-Saarivirta, "Assessing the environmental impacts of thermally sprayed WC-Co coatings deposited from zinc-process recycled feedstock", 21st Plansee seminar Proceedings, 2025.

Valmet is one of the biggest users of tungsten carbide (WC) -based materials in thermal spraying in Finland, so we are excited to be part of the Caramel project aiming to develop the recycling of tungsten carbide and cobalt. This will also support Valmet’s ambitious target to enable 100% carbon neutral production for all Valmet’s pulp and paper customers by 2030.