Wet pressing performance much improved!

N R Agarwal has been able to reduce web breaks, increase speed and boost post-press dry content on its PM5 with Valmet’s Intelligent Roll Solutions for press efficiency.

During 2017–2019, N R Agarwal’s Unit 5 in Sarigam, Gujarat, India, ordered six roll covers (rubber and PU) from Valmet for its bi-nip press section process rolls. They were giving excellent performance, and now it was time to move forward and further optimize the wet pressing performance. Valmet was ready to provide support and increase cooperation with the mill – and assist in taking the next improvement step.

Mr. Deepak Bharadwaj, Senior VP of N R Agarwal Industries, set several targets for the PM5 press section. These included improving moisture profiles and reducing web breaks. Mill also wanted to increase the machine speed but was unsure whether the press section would be able to handle dewatering at higher speeds. The dewatering capacity of the press was unknown, because the actual loading in the press section was unclear. This made the optimization and speeding up of the machine even more challenging. The trial-and-error method is always available for a speed increase, but in today’s competitive market, it is a slow and uncertain way to proceed.

Quick and cost-effective measurement, suitable to all paper machine sizes and concepts

To complement its previous roll cover delivery and to enable the mill to gain its targets, Valmet recommended its Intelligent Roll Solution, including nip measurements and Valmet iRoll Portable Press Analysis services for the bi-nip press. Indeed, there had previously been some discussion about this unique portable technology with the mill, and the customer was curious to know how it could help them.

Valmet’s iRoll Portable Press Analysis services allow paper and board makers to optimize profiles online quickly and cost-effectively, without expensive investment in equipment. This unique service can measure nip profiles under real dynamic conditions during maintenance shutdowns. Benefits can be obtained with all kind of paper machine concepts, grades, regardless of the machine size.

The mill decided to go ahead with a complete service concept consisting of Valmet iRoll portable, nip load measurements, press simulation and optimization services.

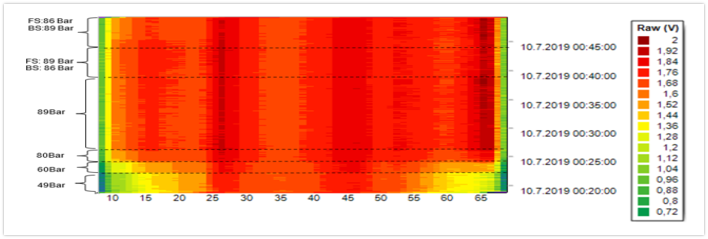

iRoll Portable nip profiles during load testing

“Achieving the best performance”

The N R Agarwal team has been delighted with the results of Valmet’s Intelligent Roll Services. The nip measurements revealed a difference between the calculated and actual load in the press section. Based on the actual load and nip profile, it has been possible to optimize the press load and roll cover crowning, thus improving runnability. Other results included an improvement of 1 percent in web dryness after the press and 1.5 percent after the bi-nip, as well as a 10-12 percent draw reduction after the bi-nip section.

With a correct picture of the nip profile, the mill could now optimize it in accordance with Valmet’s recommendations. It has been possible to increase the machine speed to 950 meters per minute according to the initial goal. Web breaks in the press section have been reduced by 20-30 percent and roll build-up has improved.

Now, the mill has a clear idea about the amount of water the press can handle with various grammages and speeds.

|

Results

|

After the optimization of the wet pressing with the Valmet iRoll Portable Press Analysis and nip simulations, we can achieve the best performance from the press section. I highly recommend it to other paper mills too.”

SUMMARY

| Location | Sarigam, Gujarat, India |

| Customer target |

Mill wanted to improve moisture profiles and reduce web breaks. They also wanted to increase the speed but was unsure whether the press section would be able to handle dewatering at higher speeds. |

| Solution | Valmet Intelligent Roll Solution for press efficiency included:

|

| Results |

The iRoll Portable Press Analysis and nip measurements revealed a huge difference between calculated and actual load in the press section. Press loads were optimized based on Valmet recommendations resulting in improved runnability and the mill has now a clear idea about the amount of water the press can handle with various grammages and speeds. |

Technical data

| Grades | Writing and printing paper as well as copy paper |

| Relocated machine with wire width | 4,550 mm |

| Speed | Range of 730 to 920 m/min |

Related articles