Valmet’s Service Center in Cernay increases roll maintenance capacity to meet growing demand

Valmet’s Service Center in Cernay, France, offers a wide range of services for optimizing the performance of its customers’ board, paper, tissue or pulp drying machines. These include roll maintenance, roll covers, spare parts, and process improvement services conducted on-site, at customer mills and remotely. Cernay is conveniently located to serve customers in Central and Southern Europe, UK, Middle East and Africa.

With its comprehensive service offering and state-of-the-art tools, Cernay Service Center strives to support its customers in achieving their targets – whether they are about increasing production efficiency, eliminating unplanned shutdowns, reducing energy consumption, improving end-product quality, and lowering the maintenance costs in long-term.

Cernay Service Center specializes in roll services such as maintenance and roll covering as well as iRoll technology, 3D roll grinding services, roll upgrades and repairs. Services are available for all types of rolls up to 13,5 m in length, 2 m in diameter and 120 tonnes in weight. In addition, Cernay offers support in process upgrades and optimization, spare parts and consumables, and paper machine clothing.

Investing in safety, efficiency, and service quality

To serve its customers even better, Cernay Service Center is currently undergoing a significant transformation that increases the service center’s maintenance capacity further. The investment reflects Valmet’s commitment to safety, innovation, operational excellence, and customer satisfaction.

The transformation includes new lines and technology upgrades such as advanced roll handling systems for safe and efficient roll logistics. The entire workshop is being reconfigured to enable smooth workflow and improved working conditions at the site. Customers will experience reduced delivery times and further improved service quality.

Customer success: Enhanced performance with Valmet’s proven roll covers

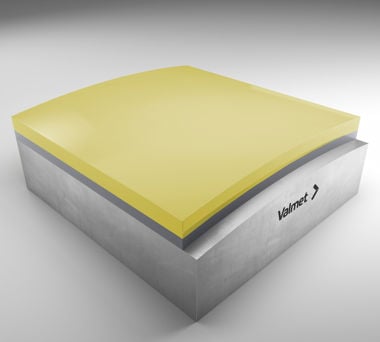

Another recent success story highlights the impact of Valmet's roll cover solutions on operational efficiency. A major European pulp and paper mill significantly extended the lifetime of its calender roll covers after switching to Valmet's Calender Roll Cover CL-W. The new cover increased roll change intervals fourfold, while maintaining high paper profile quality, resulting in substantial cost savings and improved maintenance planning.

By reducing the frequency of roll changes and associated downtime, the mill was able to free up resources, enhance production stability, and minimize unplanned shutdowns. With Valmet's expert support, the customer also optimized doctor blade performance to match the new cover's durability, further contributing to smoother operations.

These real-life examples illustrate how Valmet’s technical expertise and customer-focused approach lead to tangible improvements in performance and reliability in our customer’s production lines.

Source Valérie Lechiffre, Chief Editor at Magazine La Papeterie

Follow us on valmet.com | Twitter | Twitter (IR) | LinkedIn | Facebook | YouTube | Instagram