Seam felts meeting today’s performance expectations

Seamed press felts have evolved rapidly from a primarily safety-driven alternative into high-performance solutions capable of meeting today’s demanding press section requirements. Improvements in design, materials, and manufacturing have expanded their use across paper, board, and pulp applications.

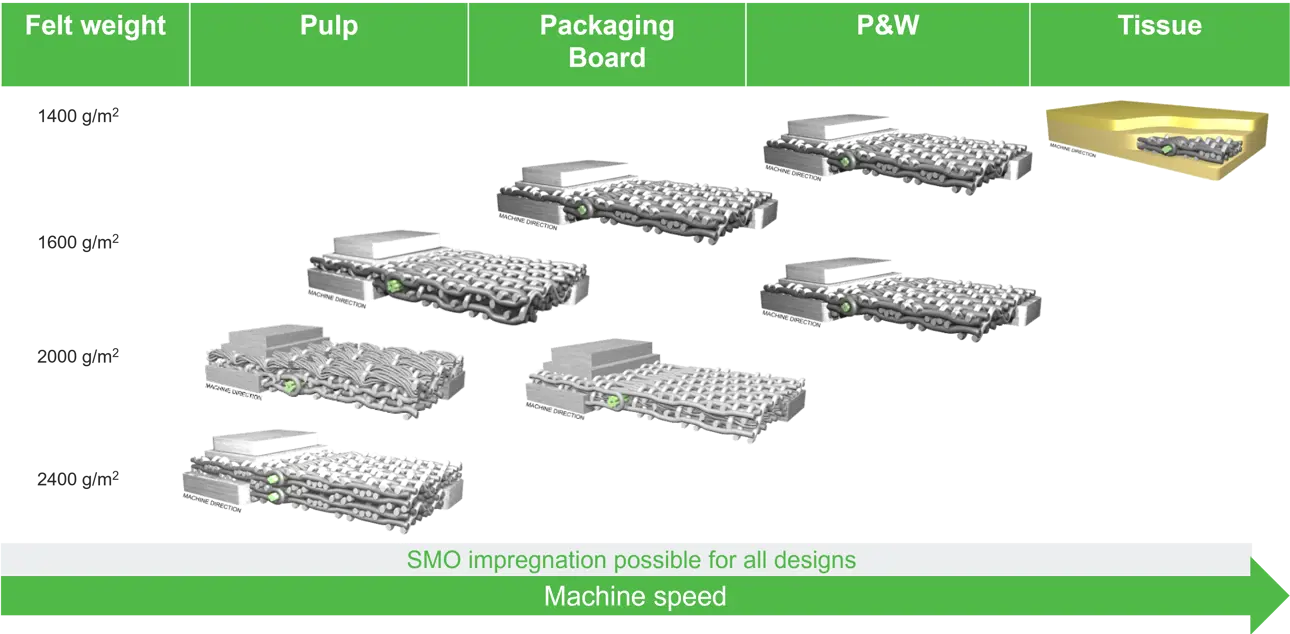

Valmet´s seamed press felt portfolio covers all the main paper grades.

Leena Silakoski, Senior Manager, Press Felts and Belts at Valmet, leads strategic oversight and development for critical paper machine clothing products that enhance machine performance and sustainability. In her role, Leena drives product excellence and innovation in press felts and belts for global pulp, paper, and tissue customers, bridging technical expertise with customer-focused solutions. In this article she explains what is driving the increased adoption of seam felts and how Valmet’s latest seam felt designs deliver performance on par with endless felts.

Seam felts have become more common in recent years. What is driving this development?

As it is commonly known, the main reason for using seam felts is safety in installation. In addition to safety aspects, customers place high value on time and manpower savings during installation, which can typically be achieved when using seam felts.

The use of seam felts has increased steadily, especially in the Americas and Europe. The main key drivers are the significant improvement in seam felt quality and wider design portfolios. Today, seam felts are used in almost all paper and board grades, excluding only the most sensitive and highest-speed machines.

How have customer expectations for seam felts evolved?

Expectations are very clear. Customers expect seam felts to deliver the same dewatering performance, runnability, and lifetime as endless felts. Seam felts are no longer seen as an alternative with limitations, they are expected to perform on the same level as endless felts. This has guided Valmet’s development work for many years.

How does Valmet support this shift with its portfolio?

Valmet has traditionally had a wide seam felt portfolio with designs covering all the main paper grades. Recent investments in our press felt production have further strengthened our capabilities and reinforced our growth in seam felts. At the same time, we have focused on developing our designs, particularly for packaging board machines and pulp drying applications, where customer needs and operating conditions are especially demanding.

Can you highlight some key seam felt designs and their customer benefits?

Certainly. Let’s start with the newest portfolio members. An important example is our Valmet TLS seam felt, developed for packaging board machines. It is a special triple-layer design, which can be described as the seam felt “brother” of our earlier Valmet EMX M endless felt designs. Both felt designs are also available as Bioneer option that utilizes bio-based raw materials for a reduced carbon footprint.

TLS offers increased water handling capacity, supporting stable runnability in high-load press sections. We already have an established customer base for TLS felts in kraftliner and folding boxboard linear press machines, where successful trials have led to a regular business.

Another example of our newest designs is Valmet PMF seam felt for pulp drying machines. This triple-layer marking felt creates benefit by remolding pulp surface topography. Increased surface area supports energy efficiency in drying section and helps with flat bale forming afterwards.

As a last example of Valmet seam felt designs to be mentioned is our unique key product Valmet SMO, a PU-impregnated seam felt that has been part of our portfolio already for some time. PU impregnation reinforces felt seam area and improves the felt running performance to the next level. SMO felts have continued their success, particularly in packaging board and pulp drying machines. In packaging board machines, customers benefit from faster break-in time, stable runnability and increased lifetime. In pulp drying, the SMO impregnation improves resistance to heat and chemicals, making it a leading solution for extending felt lifetime.

What does this mean for customers considering seam felts today?

The key message is confidence. Seam felts today are mature, high-performance products. With the right design, they can meet demanding process requirements while offering practical advantages in installation and safety. At Valmet, we continue to develop seam felts in close cooperation with our customers, ensuring that performance, reliability, and long-term value remain at the center of everything we do.

Leena Silakoski, Senior Manager, Press Felts and Belts at Valmet

Seam felts today are mature, high-performance products. With the right design, they can meet demanding process requirements while offering practical advantages in installation and safety.

Would you like to hear more?

If you wish to get further information about our seam felt offering, fill in the contact form and our experts will contact you shortly.

Contact usRead more about Valmet´s seam felt offering