Metsä Tissue Raubach installs a felt measuring beam for improved safety

Valmet Felt Profile Measurement Beam discards the need to manually enter a running paper machine for press felt profile measurement, thus significantly improving employee safety at mills.

Employee well-being is actively promoted at the mill, and investments in improving employee safety are prioritized. In 2023, Metsä Tissue Raubach contacted Valmet for a solution to measure the moisture profiles and permeability of the press felts on both the mill’s tissue machines – without a safety risk for the operator.

“Traditionally, press felt profiles have been measured manually, requiring an employee to walk across a running machine. To eliminate the obvious safety risk, we proposed installing the Valmet Felt Profile Measuring Beam. It’s a fixed beam carrying the attached measuring device across the machine, while operator can stay safely on the side of the machine,” says Michael Schindler, Mill Sales Manager at Valmet.

Good cooperation during installation

The measurement beam has been up and successfully running for several months now, improving employee safety at the Raubach mill. All the fabrics suppliers use the equipment regularly.

“The process from planning to installation was absolutely seamless. Especially the cooperation with Valmet Service Center and Project Manager in Poland needs to be noted – excellent job from everyone,” says Markus Link, Project Engineer at Metsä Tissue Raubach.

Installing additional equipment into an existing tissue machine requires more than just careful measurement and planning.

“One beam had been inaccurately measured and required some adjusting before it could be installed. Thanks to the good cooperation between Valmet and the Raubach mill staff, there was only a limited delay, and the situation was handled smoothly on both sides. I would say open communication was the key to finding alternative solutions quickly,” says Michael Schindler.

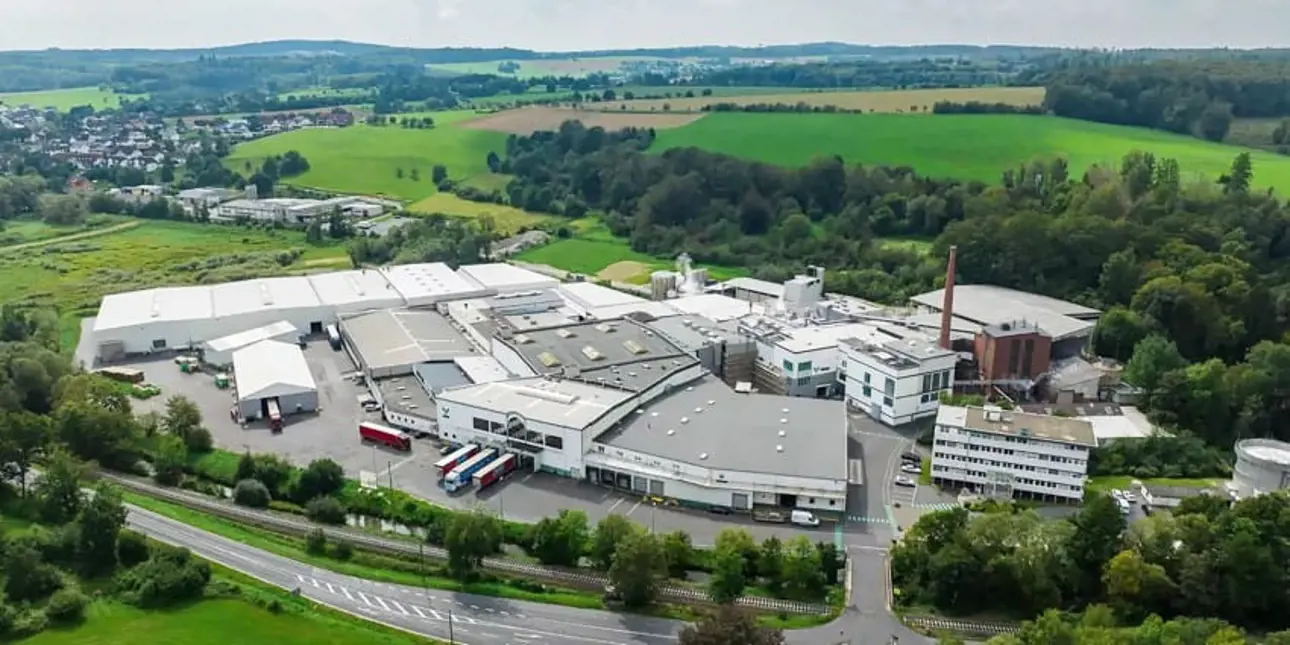

The Raubach mill was established in 1715 and is one of Metsä Tissue mills in Germany. It was the second Metsä Tissue mill to install a Valmet Felt Profile Measuring Beam. At Metsä Tissue’s Mänttä mill TM 10 in Finland, the solution has been used since 2022, and projects have been started for similar installations at the Kreuzau mill in Germany and the Mänttä mill (TM 9).

“The process from planning to installation was absolutely seamless.”