APRIL’s Kerinci mill keeps rolls running smoothly with Valmet Asset Manager

At APRIL Group’s Kerinci mill, roll maintenance is a professional game. Since the start-up of their BM1 in January 2024, Valmet Asset Manager has been the 12th player in the field, bringing structure, visibility, and efficiency to roll management. This web-based system gathers all roll-related data in one place, enabling smarter decisions and smoother maintenance operations across the entire production line.

Perttu Vikman, Senior Maintenance Manager, PT Riau Andalan Paperboard International, considers Valmet Asset Manager an excellent solution for managing the board machine’s extensive roll population of around 600 rolls.

Pangkalan Kerinci in Riau Province, Indonesia, is the home of PT Riau Andalan Paperboard International, a subsidiary of APRIL Group. The Kerinci pulp and paper mill is capable of producing over 4 million tons of pulp and 1.15 million tons of paper each year. The latest addition to the mill’s fleet is board machine 1 (BM 1) with an annual production capacity of 1.2 million tons of recyclable and biodegradable paperboard.

Board machine 1 (BM 1) is the latest addition to the mill’s fleet. It has an annual production capacity of 1.2 million tons of recyclable and biodegradable paperboard.

Before the start-up of Kerinci’s BM 1 in 2024, PT Riau Andalan Paperboard International was looking for a solution to establish a single, integrated system for all roll-related information. The goal was to have centralized visibility to the machine line’s roll population including running time statistics, and improved roll maintenance planning tools.

"Considering the size of our production line – length over 500 meters from headbox to winder with around 600 rolls in various positions; we were seeking a solution with easy but comprehensive user interface, good visualization with BM1 layout and excellent features for documentation as well as integration to our ERP SAP PM solution." says Perttu Vikman, Senior Maintenance Manager, PT Riau Andalan Paperboard International BM1.

Our choice was Valmet Asset Manager and we have been very satisfied with its easy-to-use user interface and tailored functionalities such as quickly available, up-to-date roll data that is easy to share with our operators and other colleagues,” says Perttu Vikman, Senior Maintenance Manager, PT Riau Andalan Paperboard International BM1.

A visual solution to easier roll maintenance management

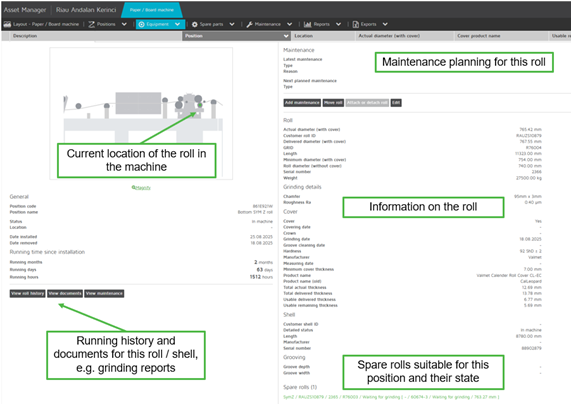

Valmet Asset Manager is a web-based computerized roll maintenance management system (CMMS). It helps store all roll-related information in one place containing roll status and location, roll positions and available spare rolls, and running time statistics. The system enables establishing visual maintenance plans for each roll and checking maintenance history quickly and easily. All teams such as operations, maintenance and mill management can have access to the system, which enhances information sharing within the organization.

“Valmet Asset Manager is an easy-to-use, visual solution that offers a good overview of a production line’s roll population. Maintenance plans are just one click away, and so is information about available spares and maintenance history. It also enables systematic follow-up of roll and roll cover running periods, helping customers optimize roll maintenance lifecycle costs and improve machine availability,” explains Jukka K. Toikkanen, Business Manager, Rolls and Workshop Services, Asia Pacific Area, Valmet.

In a single view, users can access all roll-related information — including running and service history, spare roll availability and status, as well as the maintenance plan for the specific roll. This makes roll maintenance planning much easier and keeps all departments at the mill always up to date.

Improved transparency and optimized roll lifecycle management

In addition to implementing the web-based system, PT Riau Andalan Paperboard International decided to utilize Valmet’s on-site support in daily roll-related activities and to ensure close communication and seamless cooperation between the mill’s own personnel and Valmet.

"The integration of Valmet Asset Manager has created full transparency across our departments and simplified our roll maintenance planning. Having Valmet’s roll expert on site has been a bonus and important for the efficient implementation of the system. All in all, Valmet Asset Manager has helped us to extend the lifecycle of our rolls and covers and thereby improve the overall roll maintenance cost efficiency,” Perttu Vikman says.

Text: Marianne Valta

Contact our experts here

Valmet Asset Manager is a proven system used by paper, board, and tissue mills worldwide to optimize roll maintenance. By centralizing data and enabling visual planning, it helps mills extend roll lifecycles, reduce downtime, and manage maintenance costs more effectively.”