OptiFlo headbox: where quality is made

Headbox technology plays a critical role in defining end-product quality and properties. We asked three of our experts what enables OptiFlo headboxes to deliver the best possible results for board and paper machines.

“The headbox is the most important part of a paper machine for creating high quality end product. If you don’t have quality at the start of the process, you can’t add it back afterwards,” says Ossi Pehkonen, Product Sales Manager, Headbox, Former and Press, Packaging and Paper Business Area, at Valmet.

“But there’s more to it than that. Customers want to produce the highest quality, most competitive products while also lowering costs. Valmet OptiFlo headboxes allow them to do this, letting them produce the highest possible quality with the smallest energy input and life cycle costs to their machines.”

The latest technology

“We have tested all aspects of our OptiFlo headboxes very thoroughly to ensure we have the best solution, and they utilize the latest technology in the paper and board industry. That’s why they deliver such high-quality results,” says Henry Sankala, Product Manager, Headbox, Packaging and Paper Business Area, Valmet.

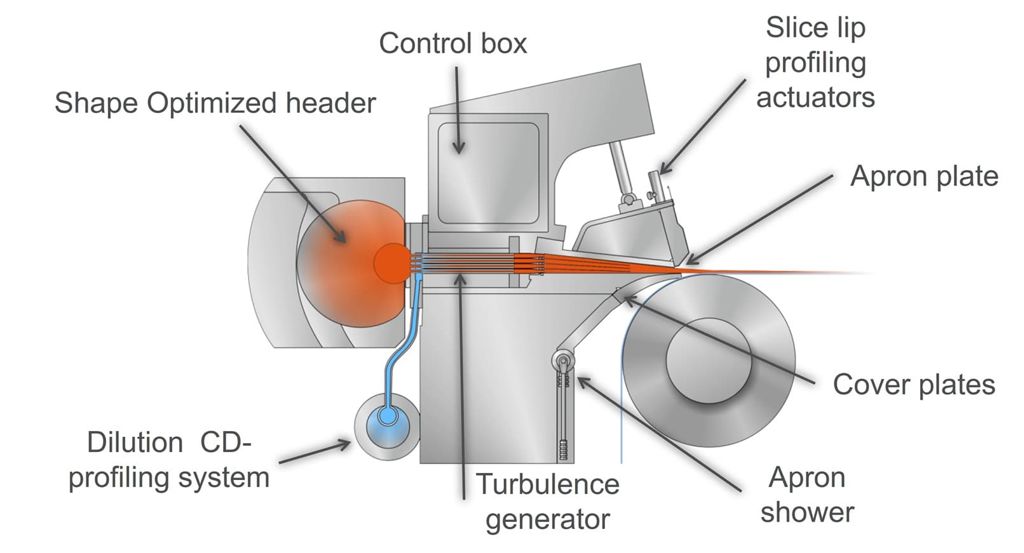

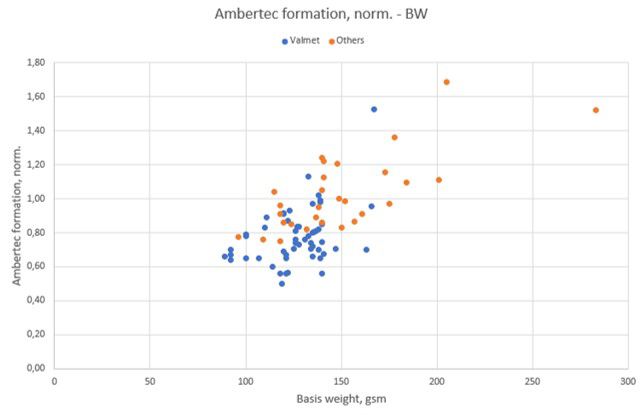

“There are several technologies that make OptiFlo headboxes really stand out,” Sankala notes. “For example, our turbulence tube design, together with the design of the vanes in the slice channel, delivers excellent flocculation breaking capability, minimized re-flocculation time, and fast and continuous acceleration to the slice. This enables a stable and uniform headbox jet, all of which leads to stable flow, and perfect formation and end product appearance. We can also affect formation and tensile ratio with our vanes by using different lengths, designs and material selection. Many things affect these properties. We have run many different types of pilot trials and confirmed the results in numerous production machines – this is the best solution available," Sankala says. “And, of course, good formation has a positive impact on strength values, as well.”

Powerful and energy efficient dilution

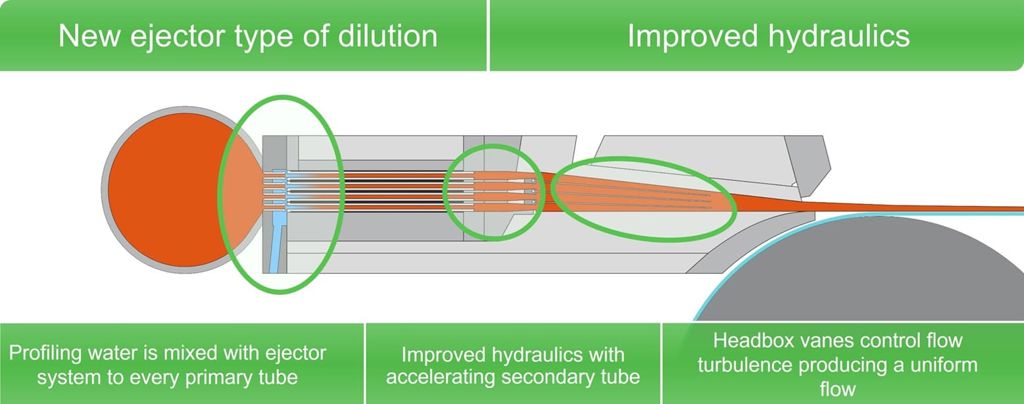

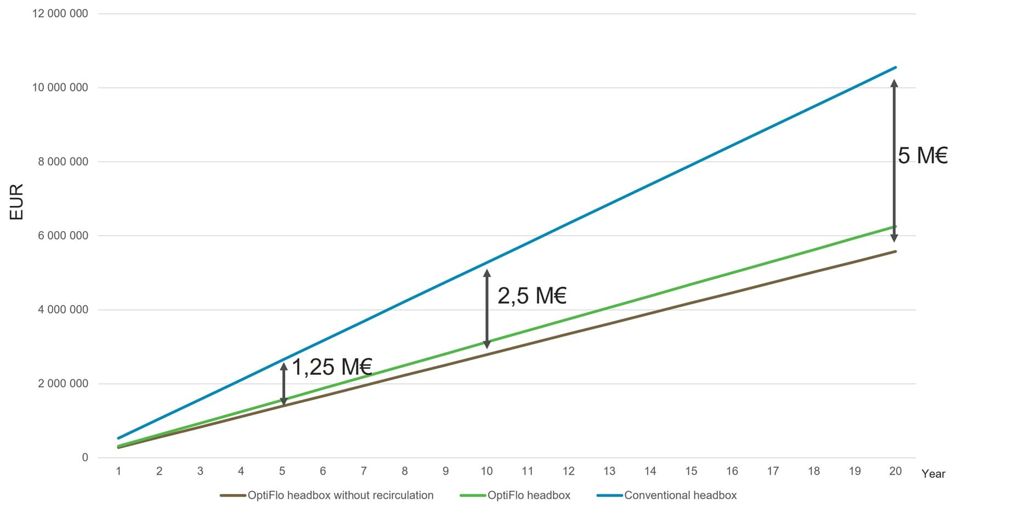

“With the right design, you can dramatically reduce headbox energy consumption,” adds Maarit Lahtinen, Senior Development Engineer, Headbox, Packaging and Paper Business Area, Valmet. “OptiFlo headboxes use a dilution feed with a single tube bank design. This means that the internal pressure loss is smaller, so it requires less pumping energy. In practice, our single tube bank design consumes up to 50 percent less dilution pumping energy than a two-tube bank structure, and it needs less water to reach the same level of quality. This gives customers the option of having more precise profiles or saving energy by pumping less. According to our calculations, OptiFlo designs consume the least energy of any headboxes on the market.”

“Our solution is unique in the market and much more powerful – up to 30 percent more powerful dilution than other options,” adds Lahtinen. “The dilution happens right at the turbulence generator with overlapping tubes, which makes it more accurate than conventional technologies without overlapping. This reduces stripes, producing better quality.”

Modular design for life time benefits

“One of the most forward-looking aspects of OptiFlo headboxes is their modular structure. This makes it easy and cost-effective for customers to upgrade their machines in the future,” says Sankala. “Whenever you want to upgrade your machine, OptiFlo headboxes are ready for it. The same headbox frame structure can be easily modified and rebuilt for a different concept, for example, to change paper grade, machine speed, flow rate or upgrade a one- layer headbox to a layering headbox.”

“The modular structure also has a real benefit for the lifetime costs of a paper machine,” he adds. “With OptiFlo headboxes you don’t need a major rebuild to upgrade your machine – changing the relevant parts is very quick and easy. This means that if your production requirements change, you can make the necessary modifications cost-efficiently. You can get the upgraded machine back in business quickly, with minimum construction work and a short shutdown time.”

Piloting for perfection

“At Valmet, we are always testing and studying ways to improve our products and make them even better, and this applies to our headboxes, too,” says Pehkonen. “We have two pilot machines at our pilot facilities in Jyväskylä, Finland, where we can test every part of a paper machine, from the wet end to the dry end for all paper and board grades. We have tested all possible configurations and aspects of our OptiFlo headboxes to find the best solutions available.”

“We can do this for our customers, too. Pilot trials are a very good way of demonstrating the kind of end product quality that they can produce. We can do trial runs with any OptiFlo headbox, using the exact parameters and recipes they want, and take measurements and verify that they can reach the right level of quality. This greatly mitigates risks especially in grade conversion projects.”

“With OptiFlo headboxes, customers get reliable technology from a reliable supplier. When they choose Valmet, they can maximize the quality of their end products while minimizing their risks,” he concludes.

Text: Peter Cura

Learn more about our OptiFlo headbox offering

Watch our latest headbox related videos and read customer success stories where OptiFlo headbox was the star of the story