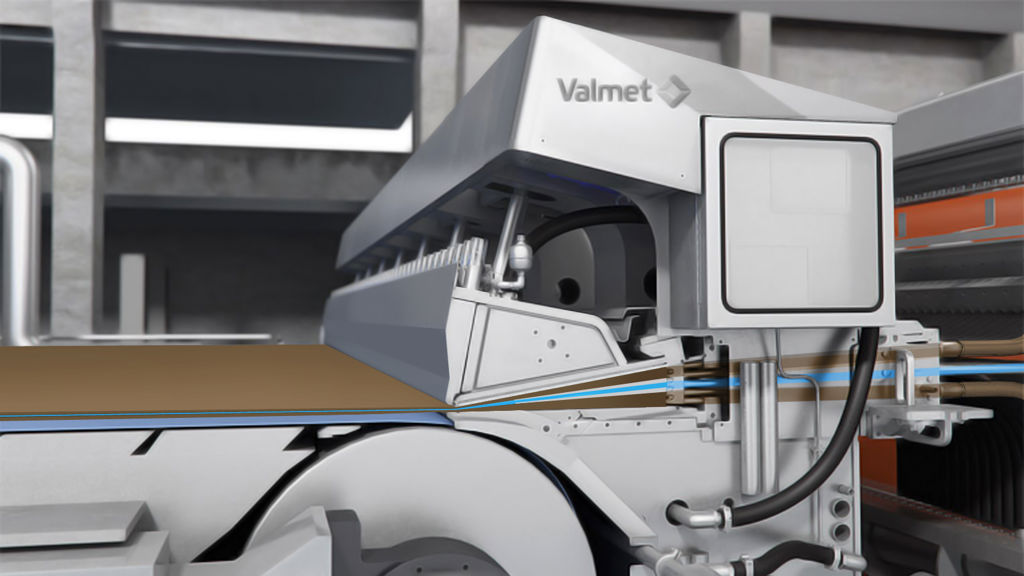

OptiFlo headbox: lifecycle benefits built in

The right choice of headbox can help paper and board makers optimize many factors, including upgradeability, end-product quality, energy efficiency and life time costs. OptiFlo headboxes are designed to meet all these goals, today and tomorrow.

“Valmet has a long history of manufacturing headboxes and we apply our headbox knowledge for our customers’ benefit,” says Ossi Pehkonen, Product Sales Manager, Headbox, Former and Press, Packaging and Paper Business Area, at Valmet. “We have delivered and installed thousands of headboxes around the world, so we have a very good understanding of what we’re doing,” says Pehkonen.

“And because we have our own R&D facilities, we’ve been able to look at headboxes from all possible angles. We have really thought about them and studied them, testing the latest hydraulics, technology and manufacturing. And it is this combination of experience, attention to detail and continuous improvement that led us to our OptiFlo headboxes. These produce the highest possible quality with the smallest energy input, and they are designed not just to answer the needs customers have now but also the needs they might have in the future.”

Efficient installation and start-up

“Valmet’s R&D and headbox manufacturing facilities are both here in Jyväskylä in Finland,” Pehkonen adds. “This means that we can very easily discuss ongoing projects and our customer’s needs with the people who are making each OptiFlo headbox. We can really go into the details.”

“In addition, we have two different pilot machines in the same location, so we can do headbox pilot trials and run trials with different former types, like Fourdrinier, hybrid and gap formers. Customers can come here and discuss what they want and see the real results they will get. We can test their furnish and choice of headbox to make sure they will achieve the desired quality of end product. When we already know exactly how to optimize their machine, it makes installation and start-up much more efficient,” Pehkonen says.

Effective and reliable pulsation damping

“OptiFlo headboxes use a modern design for pulsation damping that’s maintenance-free, with no moving parts – the attenuator tank has fixed cleaning showers inside,” says Henry Sankala, Product Manager, Headbox, Packaging and Paper Business Area, Valmet. “Valmet’s attenuator tank principle is based on, 1) pressure loss over the tank with a perforated plate that dampens pulsations and, 2) an air pad that dampens pulsations. It’s proven, reliable technology. We can also replace other dampers with our solution if customers are not satisfied with the existing pulsation damper technology on their headbox.”

Ball valves for dependable dilution

“Another aspect is that OptiFlo headboxes use specially designed ball valves that do not clog, resulting in less machine down time and less broke,” says Pehkonen. “The dilution valves in OptiFlo headboxes have a broad ball on the inlet side to prevent clogging. On the outlet side, there is a V-shaped section that enables linear flow control. The entire valve has a robust, durable construction with a stainless-steel ball and stainless-steel body, and a low friction gasket, for accurate and reliable operation.”

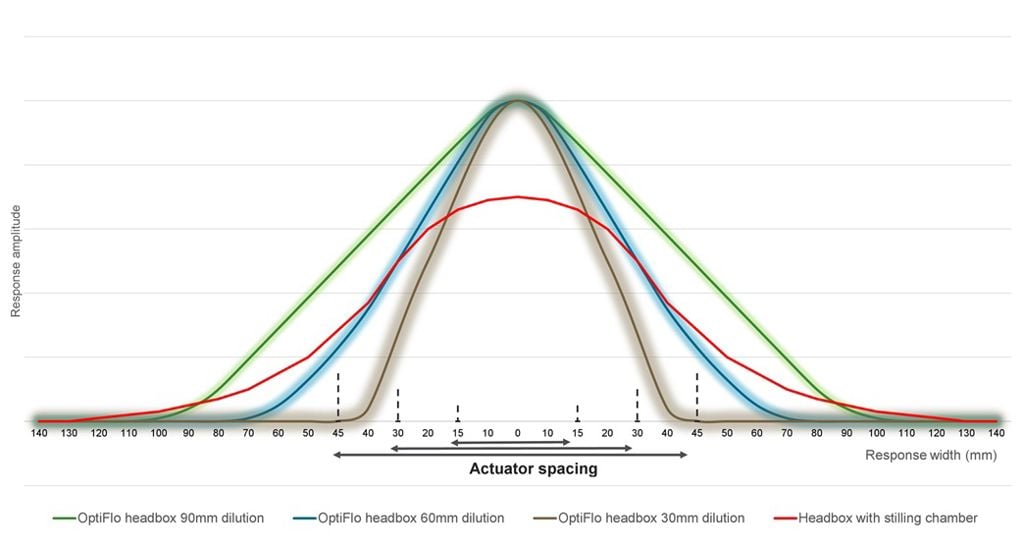

“It’s also worth mentioning that OptiFlo headboxes are now available with three different dilution actuator spacings,” he notes. “We recently added a 30 mm spacing, and this means that Valmet now offers 30 mm, 60 mm, and 90 mm actuator spacing, ensuring the best dilution control for each specific case.”

Flexible layering options

“OptiFlo headboxes are available with layering versions, for two- and three-layer applications and with or without Aqua layering technology, so customers can get exactly what they need for their production,” says Maarit Lahtinen, Senior Development Engineer, Headbox, Packaging and Paper Business Area, Valmet. “With layering, a single OptiFlo headbox can feed different stock into each layer so that the structure of board can be further optimized. This gives the customer the flexibility to choose furnishes based on the different functional properties of each layer.”

“It’s a cost-effective concept that enables you to produce two- or three-layer sheets using only one headbox and one forming unit, instead of needing two or three headboxes and forming units. We can also deliver a single layer OptiFlo headbox with the layering and Aqua layering technology as options. The modular design makes it easy and more cost-effective to rebuild the headbox to include layering in the future when production requirements change,” she says. “For example, OptiFlo makes it easy to convert a paper machine from fine paper, which is usual single layer, to liner grade, which is often two ply. All with minimal rebuild costs.”

Trouble-free operation and maintenance

“We have designed OptiFlo to be easy to maintain and keep clean, to maximize the lifetime of the components. Maintenance personnel have good access to every maintenance position, with quick access through the side doors. This means that all the critical components are easy to replace without big rebuild work or long shutdowns. This saves time and money, and maximizes productive uptime throughout the whole lifecycle of the machine,” concludes Sankala.

Text by: Peter Cura

Learn more about our OptiFlo headbox offering

Watch our latest headbox related videos and read customer success stories where OptiFlo headbox was the star of the story