From vision to victory: Ajin P&P achieves unmatched performance with Sleeve roll technology

Outstanding high-performance result from world’s first Sleeve roll on their BM 3, together with excellent co-operation and support from Valmet, encouraged Ajin P&P Co., Ltd., to repeat the order of a forming section rebuild for their BM 2 multi fourdrinier forming section, with Sleeve roll in the combining position.

Strategic investments driven by customer centricity and quality

“For us there are three main points to consider when we are planning for investments: customer centricity, end product quality, and risk & innovation,” Dr. Jin-Doo Kim, CEO, Ajin explains. In principle, from customer centricity and quality perspective, investment decisions are always driven by the need to improve competitiveness and, most importantly, to satisfy customer requirements.

The motivation for our investments is the desire to achieve superior product quality, especially uniformity and internal bonding strength. The key is delivering consistent, high-quality paper that meets customer expectations for stability and runnability in their converting processes. This customer satisfaction is the foundation for Ajin’s competitive power and long-term success, Dr. Kim describes.

“We also need to be willing to take calculated risks and pursue disruptive and innovative solutions, even when these differ significantly from conventional industry practices,” Dr. Kim states. The adoption of Sleeve roll technology was a bold move to leap ahead of competitors, rather than merely trying to catch up using the same methods and principles that have been in place for decades and longer.

“Ajin is not a big company, and we need to evaluate all investments carefully. Also, it is not possible for a company of our size to execute large rebuild and improvements projects as one project. Despite these limitations, we always prioritize investments that can yield the greatest improvements in quality and customer satisfaction, with a step-by-step approach to gradually enhance our competitive position. This is achieved through several smaller improvements spanning over several years or even a decade. Both Sleeve roll investments are crucial steps in this long-term development,” Dr. Kim concludes.

BM 2 produces test liner grades in 115 to 250 g/m² basis weight range from Korean OCC (Old Corrugated Container). The multi fourdrinier forming section was upgraded with Sleeve roll in the combining position in September 2024.

Sleeve roll technology: a genius game-changer in forming section technology

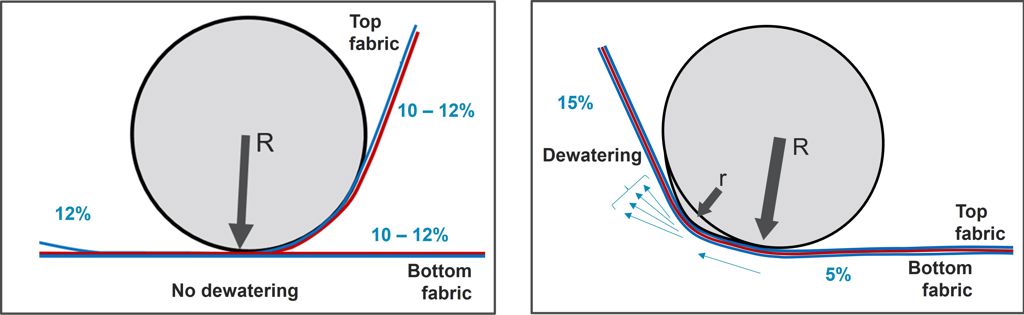

Sleeve roll technology is a major breakthrough in forming section technologies. It replaces traditional vacuums and suction boxes with a new genius principle where the web is compressed between two forming fabrics against a small radius shoe creating very high dewatering pressure. With the basic circle before the shoe of the Sleeve roll, the fabric tension creates moderate pressure. When passing over the variable radius shoe, the dewatering pressure increases steadily toward the maximum compressing pressure of up to 150 kPa.

With conventional forming section technologies, dewatering pressure is typically around 15 to 40 kPa, and with a couch roll or HiVac, it is typically around 60 to 70 kPa. The steadily increasing dewatering pressure in the Sleeve roll shoe causes no defects to the web, even with very low ingoing consistency. This gentle yet effective approach of the Sleeve roll technology harnesses fabric tension and shoe interaction to gradually escalate dewatering pressure, resulting in efficient water removal without compromising paper integrity.

Dr. Kim praises the Sleeve roll technology of being genius innovation, bringing several significant advantages for them. “Sleeve roll technology fundamentally changes the forming section. We have seen higher dewatering capacity, improved efficiency at higher speeds, and better performance with lower basis weights. There has also been a massive improvement in internal bond, as Ajin samples now have up to 52% better internal bond than market samples. Sleeve roll technology is self-regulating with no parameters to adjust, easy to operate, reducing operator stress, and simplifying and speeding up grade changes. It has proven durable and requires minimal maintenance,” Dr. Kim confirms.

On left, Conventional ply bonding method: Plies are combined with an open roll with no dewatering - Limited possibility to transfer fines over the ply interface

On right, Ply bonding with Sleeve roll technology: Very high dewatering pressure between forming fabrics against the small radius shoe compresses plies together - Possibility to transfers fines over the ply interface

Sleeve roll technology is installed on both of Ajin’s board machines, BM 3 and BM 2. BM 3 is the world's first Sleeve roll, in hybrid former, and it has been operational for over 4 years now. BM 2 is the third installation globally, in a combining position on a multi fourdrinier former, and it has now been running over a year. “There has been no issues or problems with either of the Sleeve rolls’. They are extremely stable in operation. BM 3 has been running over 4 years without any major maintenance. The lifetime of the Valmet Sleeve Roll Belt is also currently over a year, for which we are very satisfied. Same goes with the forming fabrics lifetime,” Dr. Kim explains.

Measurable gains in quality, efficiency, and competitive advantage

“The Sleeve roll has led to significant competitive advantage for us. Dramatical improvements in paper quality, especially in formation and internal bond, being the most important. On BM 2 the internal bonding strength is nearly 300 J/m², compared to market samples which are below 200 J/m². We have excellent machine direction (MD) and cross direction (CD) stability and consistent quality. Steam consumption is reduced by up to 8%, with energy consumption maintained or reduced, while there has been a notable increase in machine speed. Time efficiency has increased, grade changes are faster and there has been 62% less sheet breaks,” Dr. Kim lists.

Improvements achieved on BM 2 after installing the Sleeve roll

Speed increased by

50

m/min

Improved time efficiency:

62%

less sheet breaks

Productivity improved by

8%

Up to

52%

better internal bonding strength than in market samples

Steam consumption reduced up to

8%

even though speed increased

Strength additives dosing reduced up to

60%

The investment has resulted in measurable improvements in product quality, operational efficiency, and customer satisfaction. The company’s reputation has grown, with both customers and competitors taking notice of the advancements achieved through these investments.

Advancing sustainability through recyclability and energy efficiency

As a leading Korean corrugated board and packaging manufacturer, Ajin has played a leading role in the industry for over 45 years. Sustainability is of utmost importance for Ajin and they aim to lead the recyclability in paper industry. As an example, Dr. Kim sees it imperative for the industry to develop in the direction where high-quality, functional papers can serve as alternatives to plastics and are easier to recycle.

Besides recyclability, Dr. Kim also emphasizes the importance of reducing energy consumption in papermaking for both cost and environmental reasons. The Sleeve roll technology addresses this issue to the point, as it has enabled significant energy savings, particularly in steam consumption, for Ajin.

Long-Term partnership and co-creation

Dr. Kim highlights the long-standing collaboration with Valmet, describing it as true co-creation where both parties have contributed ideas and innovations over decades. He emphasizes open communication, mutual learning, and support between the teams, with a strong culture of knowledge sharing. This partnership has led to the development and commercialization of several innovative technologies, including the Sleeve roll.

“I am a lucky guy to have met and partnered with such a company as Valmet,” Dr. Kim concludes.

Text: Elsa Sinjaga

Further information on the Sleeve roll technolgy