At the forefront of safety development

Practical safety solutions developed in cooperation with our customers

Safety and usability are integrated into every aspect of our machine design. We aim to set the industry standard through continuous development and collaboration with customers. By customer cooperation and the latest technologies, we work to ensure our machines are safe, user-friendly, and high-performing.

Dedicated to safety and usability

The present-day requirements for machine safety are much higher than those the industry has been used to over the past few decades. Valmet is committed to going above and beyond those expectations. We not only meet modern requirements but also aim to ensure exceptional usability of all our safety solutions.

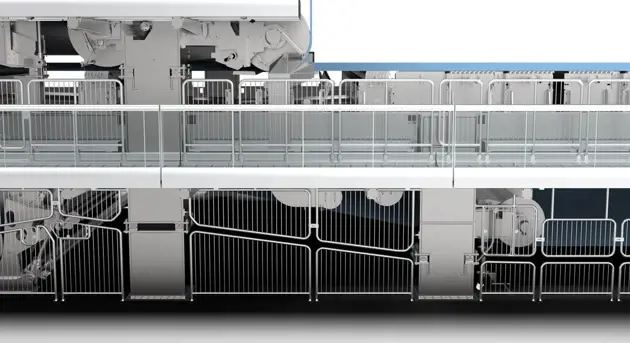

Well-designed machine safety is not just about adding the required safety functionalities. For example, as guard rails between the walkways and the machine are replaced by larger guards to ensure user safety during production, the need for quick-detach guards and other smart solutions enabling fast access to the machine during maintenance breaks becomes greater than ever.

Smart design prioritizes both safety and usability.

Practical safety solutions developed in co-operation with our customers

Achieving a new benchmark in machine safety without compromising usability is no small feat. This requires constant dialogue and cooperation with our customers, carefully listening to and considering the machine operators’ points of view.

For us, this is not just empty words. We have a proven track record as the industry trend-setter with a plenty of recent examples to showcase this. These include, but are not limited to:

- Quick-detach safety panels for the wet end that allow fast access to the machine without compromising the fall protection

- Multiple solutions that enable users to perform maintenance tasks and adjustments from the safe side of guards while the machine is running, such as our doctor blade change device and wet end grease dosing module

- The new Valmet Dryer Fabric Cleaner Omni that allows for quick detach of the washing head for maintenance

As the boundaries of the process technology are pushed year by year, the level of safety for operators is also improved. Going back to major benchmarks such as OptiConcept M, which introduced clean and spacious walkway layouts, Valmet remains devoted to being at the forefront of this development with several initiatives being pursued even at this very moment. After all, it is only fitting that with state-of-the-art machinery comes a state-of-the-art level of safety and usability.

Read about safety and paper machine design

Want to talk to our board & paper experts?

If you wish to get further information like technical specifications or details, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact our expertsExplore our latest board and paper press releases

- Jan 29, 2026Valmet launches new Bioneer press roll covers with reduced climate impact

- Dec 19, 2025Muoto products produced with Valmet 3D Fiber technology piloted at Valmet’s Jyväskylä location

- Dec 8, 2025Valmet has completed change negotiations for temporary layoffs in the Packaging and Paper business area and Global Supply unit in Finland

- Nov 26, 2025Valmet supports Wuzhou Special Paper’s transition to recycled board grades with a complete paper machine conversion rebuild

- Nov 5, 2025Valmet to start change negotiations regarding temporary layoffs in the Packaging and Paper business area and Global Supply unit in Finland

- Sep 16, 2025Valmet strengthens customer value by delivering a high-end sack and kraft paper machine for Guangxi Jianhui Paper in China

- Aug 21, 2025Valmet to supply two papermaking lines to a customer in China

- Aug 18, 2025Successful start-up of Sappi North America’s rebuilt board machine PM 2

- Aug 13, 2025Valmet launches next-generation Valmet Conical Refiner Conflo L model, designed for higher capacity and efficiency

- Aug 7, 2025Successful start-up at Liansheng Pulp & Paper’s coated board making line PM 2