Resource efficiency

4-step approach to resource efficiency in paper and board making

Discover Valmet’s 4-step approach to develop resource-efficient paper and board production. By applying these principles, you can reduce energy, water, and raw material consumption while improving quality and production efficiency. This not only boosts operational efficiency—it also strengthens your sustainability efforts by minimizing environmental impact and supporting responsible manufacturing.

What is resource efficiency?

Resource efficiency refers to how effectively production equipment is managed to minimize unnecessary losses of energy, water, and raw materials. In paper and board making, this means using electricity, steam, fresh water, and raw materials as efficiently as possible while also reducing downtime and waste (broke). By minimizing resource consumption and maximizing production, paper and board producers can improve sustainability, outperform competitors, and meet customer expectations.

Continuous development through Valmet's 4-step approach

The 4-step approach to resource efficiency provide a concrete guide for process development and for mapping, prioritizing, and implementing various actions. It ensures that development actions are completed, followed up, and adapted to meet evolving internal and external goals. This isn't a one-pff project - it's a continuous process.

Key benefits of the 4-step approach bring measurable advantages:

- Improved operational efficiency

- Reduce downtime, energy waste, and raw material losses.

- Enhanced sustainability

- Support environmental goals by minimizing resource consumption.

- Data-Driven decision making

- Use benchmarking and quantification to guide strategic improvements.

- Tailored solutions

- Adapt the approach to fit each customer’s unique process and equipment.

- Long-term competitiveness

- Stay ahead of industry standards and customer expectations.

- Scalable development

- Apply the model to both new and legacy production lines.

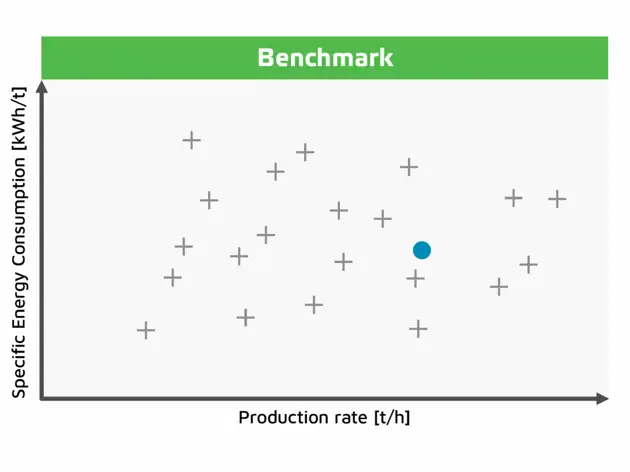

Step 1: Benchmark

“What does your current performance look like against the competition or best available technology (BAT), and industry practices?”

This step involves evaluating your current operations to understand where you stand. Benchmarking helps identify gaps and opportunities by comparing your performance with industry standards.

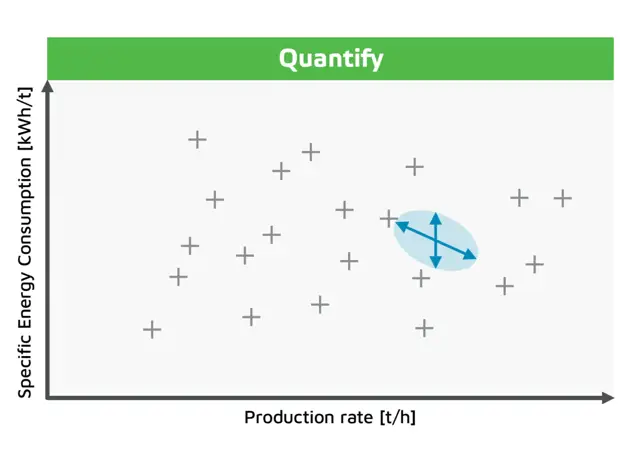

Step 2: Quantify

“Where is your improvement potential located specifically, and what actions do you need to take to utilize that potential?”

This phase dives into the details. It involves data collection, analysis, and creating an improvement action roadmap. Quantifying helps prioritize actions based on impact and feasibility.

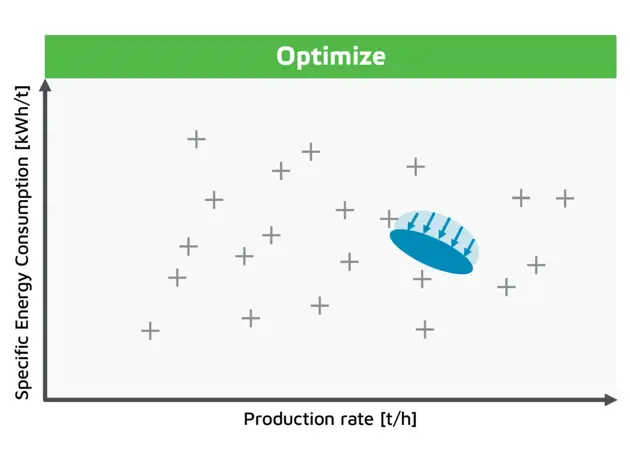

Step 3: Optimize

“Implement identified development actions to optimize your current production processes.”

Optimization focuses on executing the improvement action roadmap. This included e.g., process improvements, layout modifications, automation upgrades, and fine-tuning operations to reduce waste and increase efficiency.

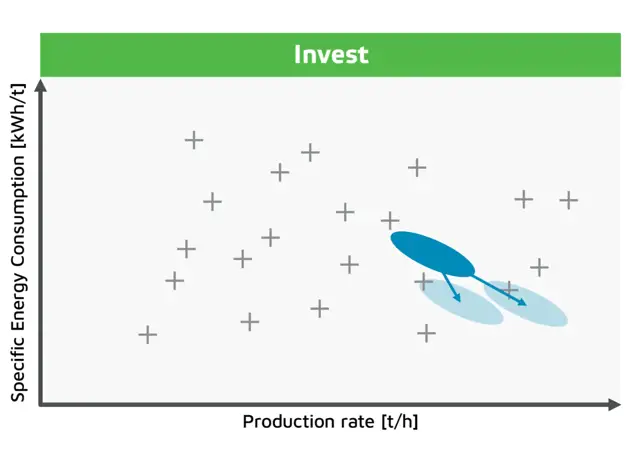

Step 4: Invest

“Implement the best available technology and follow an investment plan to ensure continuous long-term development.”

Investing in modern technologies ensures sustainable growth. Whether it's digital tools for newer machine lines or equipment modernization for older ones, this step secures long-term resource efficiency.

Related articles and references

Valmet’s 4-step approach to resource efficiency guidebook

How efficiently do we use electricity, steam, fresh water, and raw materials in paper and board production?

Valmet’s 4-step approach to resource efficiency focuses on how effectively production equipment is managed to minimize unnecessary losses of energy, water, and raw materials. It also considers production performance factors such as downtime and the amount of broke generated.