Valmet´s solutions for reject handling

A valuable stream of your board making process

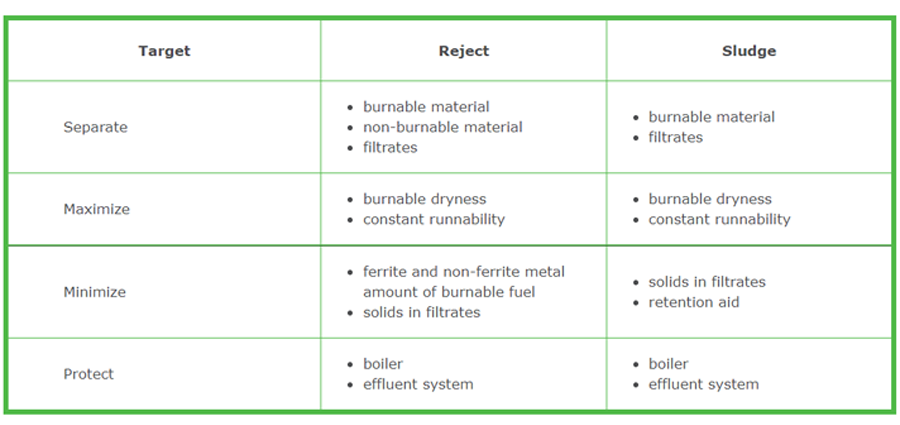

Sustainable recycled fiber lines require proper reject handling systems to operate economically. This means minimized process material losses and efficiently recovered resources like fibers, water, and energy, as well as minimized waste disposal.

Optimal reject handling systems help you to convert rejects into valuable energy and new raw material sources.

Coarse reject handling

A typical coarse reject handling system is used for coarse rejects from pulping, HC cleaning, and coarse screening areas. The system includes screw drainers for secondary pulper heavy reject and HC cleaner reject and a screw press for pulper light reject and coarse screening reject. The dewatered coarse rejects are collected in containers or bunkers and transported for further processing or disposal in a typical outlet consistency of up to 60-65%.

Sludge handling

A typical sludge handling system is used for fine rejects from screening and cleaning. The system includes a flocculation tank, rotary screen thickener and screw press. Sludge is fed at low consistency into the thickening system from a collection tank. When required, polymer is added to the sludge immediately prior to the flocculation tank. The conditioned sludge flows from the tank to the high consistency rotary screen thickener, where the thickening process begins. The pre-thickened sludge is then fed to the sludge press for final thickening up to a consistency of 50 to 60 percent.

Water treatment

Recycled fiber line water treatment is done with DAF's or Dissolved Air Flotation systems. Reject handling system filtrates are collected in a tank and pumped to a DAF. In the DAF remaining particles in the water are flocced together and carried to the surface with microbubbles. From the surface the particle flocs are scraped off and the clarified water is sent to effluent treatment plant.

Another common use for a DAF system in a recycled fiber line is for light weight cleaner reject clarification. Using a DAF enables the clarified water to be reused in the process.

Value-added reject handling equipment

To minimize the amount of material going to landfill coarse rejects can be processed further already in the reject handling system. Shredders are used to detach and chop the rejects to smaller pieces. Magnets and eddy current separators are then used to separate ferrous and non-ferrous metals, respectively. The remaining burnable fraction is cleaner and therefore more efficiently processable.