Sizing success with Nelprof – unlocking butterfly valve potential

Opening the flow – why sizing sets the stage

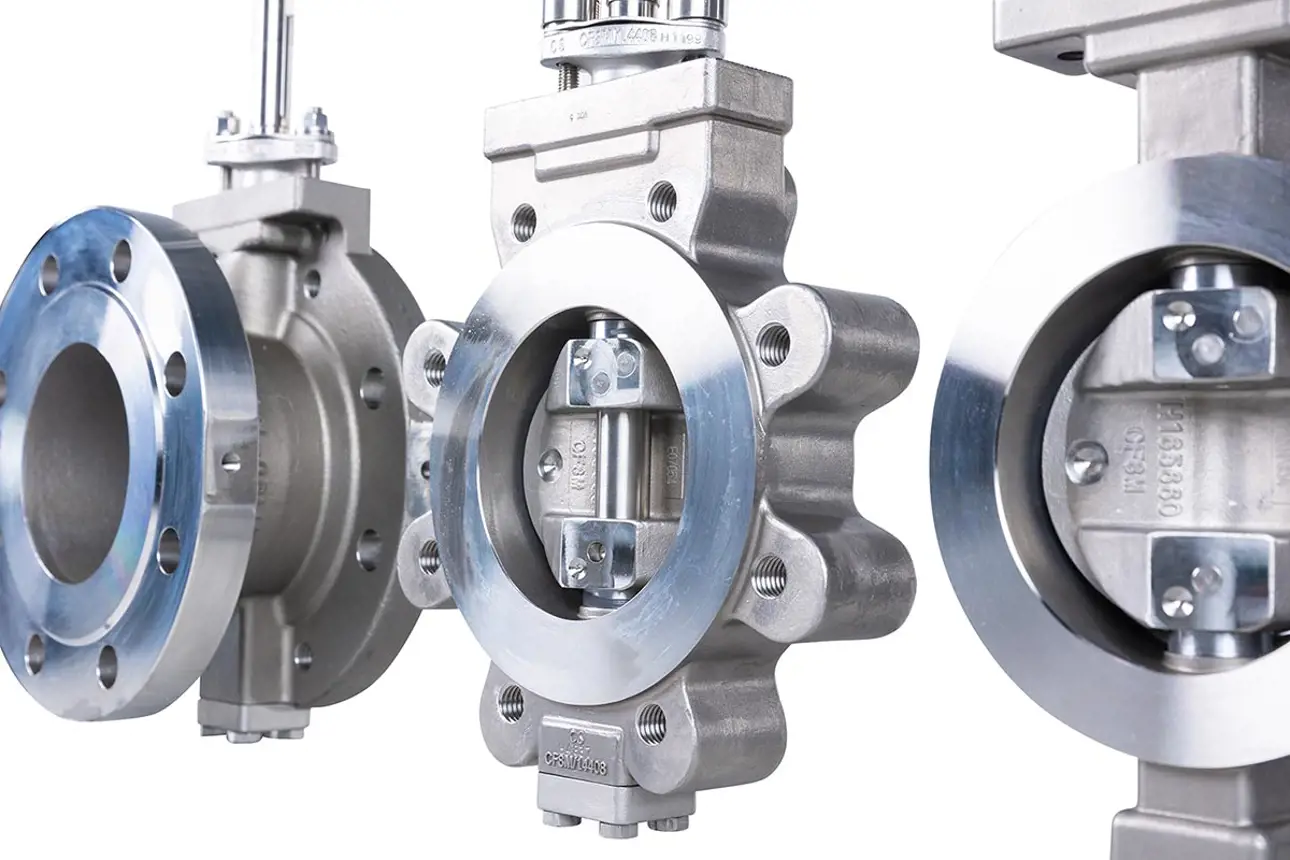

Valve sizing is a critical step for achieving precise, reliable and stable flow control as well as improved process performance, especially when using Valmet’s butterfly valves in demanding control applications. Butterfly valves are valued for their compact design and versatility, but their performance depends heavily on correct sizing and selection. This is where Valmet’s valve sizing and selection software, Nelprof™, makes a real difference.

The heart of control – why getting sizing right matters

The installed flow characteristics of a valve are influenced by both the valve’s inherent design and the specific process conditions. In control service, factors like pressure drop, flow velocity, noise, and cavitation risk must be carefully considered. Undersized or oversized valves can lead to poor controllability, increased wear, and even process instability.

A new valve deserves a new sizing

Valve sizing is important not only in new projects, but also when an existing valve is being replaced with a new one. Process values and operating conditions can change over time, meaning the original valve may no longer be the optimal solution. Sometimes the old valve may have become a bottleneck in the process, limiting performance or causing other issues. That’s why it is recommended to always perform sizing calculations in replacement cases as well – this ensures that the new valve serves the process in the best possible way and enables efficient and reliable operation.

Customer gains – the real value of smart sizing

Proper valve sizing ensures that butterfly valves operate within their ideal control range, which leads to smoother process control and fewer operational issues. Optimized sizing reduces energy losses, minimizes actuator oversizing, and extends valve life, resulting in lower total cost of ownership and reduced maintenance expenses. Correct sizing helps prevent failures and unplanned shutdowns, supporting safer and more reliable plant operations. By analyzing the process conditions, optimal performance is ensured.

Nelprof in action - making sizing effortless and accurate

Nelprof is a free, web-based tool that makes butterfly valve sizing easy and accurate for control applications. It simulates real process conditions – including pipeline effects, pressure drops, and flow regimes – to ensure the selected valve is truly optimized. Nelprof predicts noise and cavitation risks, checks actuator sizing, and helps users choose the optimal valve size to meet process control needs.

A real-world win

For example, in one case, the initial plan was to replace a steam control valve with the same size as the old one. However, after entering updated process data into Nelprof, it became clear that a different valve size was needed to maintain stable control and avoid excess noise. By following Nelprof’s recommendation, the customer achieved reliable performance and prevented future operational issues, demonstrating how Nelprof supports smarter, data-driven decisions in real-world applications.