Electric heaters & hydrogen burners for heating up the Yankee Hood

Mar 21, 2024

Heating up the Yankee Hood to optimize heat transfer and improve the uniformity of temperature distribution is a critical process that requires efficient and reliable solutions. This article explores the benefits of using electric heaters and hydrogen burners for this purpose, highlighting their advantages and integration in the tissue paper making industry.

Potential advancements in electric heaters and hydrogen burners hold great promises for the tissue paper industry. Electric heaters are known for their energy efficiency, precise temperature control, and ability to quickly reach the desired operating conditions. They also offer a clean and environmentally friendly solution, eliminating the need for fossil fuels. Hydrogen burners provide a high-intensity flame with minimal emissions, ensuring optimal combustion efficiency.

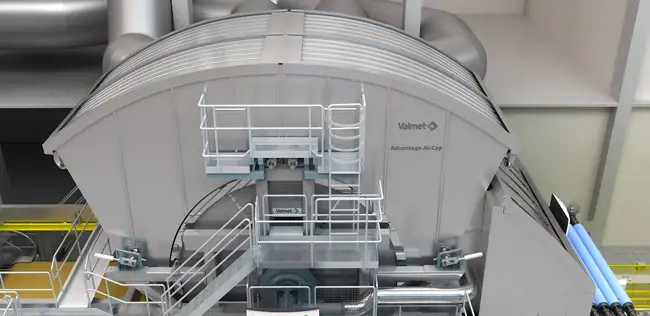

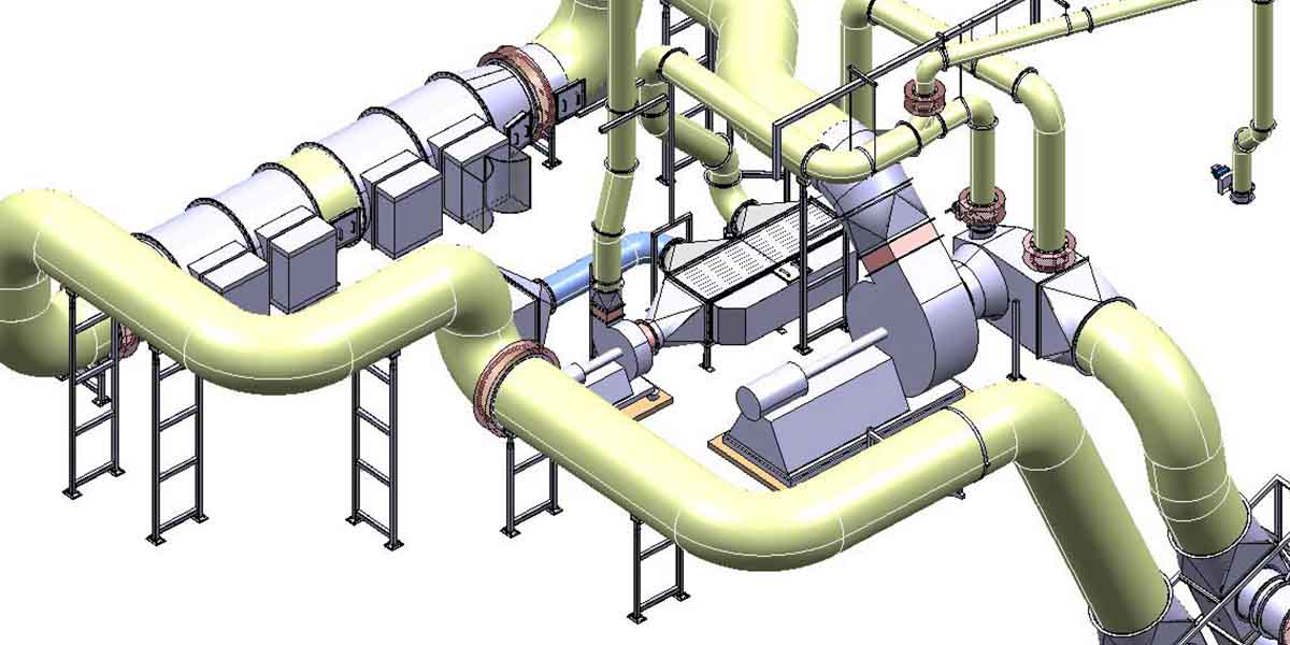

Introduction to Yankee Hood heating

The Yankee Hood plays a crucial role in the tissue manufacturing process. Efficient heating within the Yankee Hood is essential for achieving high-quality tissue paper with the desired properties.

Paolo Vezil, Sales Manager, Valmet, has long experience working with air systems and burners for tissue making.

Advantages of Electric Heaters

- there will be no water generation from burning process to be handled and exhausted

- there is no need for combustion air with high pressure fan

- a better air balance can be more easily achieved and optimized based on energy efficiency and runnability

Energy efficiency and cost savings

Considering the natural-gas-to-electricity cost ratio and keeping in mind the above-mentioned aspects, the application of electric heaters can result in significant cost savings for tissue paper manufacturers. Moreover, any advantage deriving from Carbon Tax provisions further increase the overall savings. Additionally, electric heaters require minimal maintenance, reducing operational costs.

Flexibility to serve all needs

Paolo makes it clear that electric heaters can be applied both to new installations and rebuilds,

They can serve as stand-alone heating source or be installed with another heating method or fuel for example natural gas burners.”

When electric heaters are employed to replace traditional burners, there is no major change in the drying philosophy, as both blowing speed and temperature conditions remain the same as before.

Environmental benefits

Opting for electric heaters brings significant environmental advantages. Unlike traditional combustion-based heating methods, electric heaters offer sustainable heating solutions by eliminating the use of fossil fuels and reducing greenhouse gas emissions. They produce zero emissions at the point of use, reducing the overall carbon footprint of the entire tissue manufacturing process. With the option to generate electricity from renewable sources, such as wind or solar power, tissue paper manufacturers can further enhance their sustainability efforts.

A highlight on the main aspects of Electric Heaters:

|

Features: |

Benefits: |

|

|

|

|

|

|

|

|

|

Advantages of Hydrogen Burners

If we explore the benefits of using hydrogen burners for the purpose of heating up the Yankee Hood, we see a range of advantages.

Flexible solutions

Hydrogen can be used as thermal energy carrier for air system burners, replacing partially or entirely fossil-fuel traditional solutions.

Paolo is highlighting the advantage of flexibility with these burner solutions,

This burner solution can be designed to operate with 100% natural gas, 100% hydrogen and all the possible natural gas and hydrogen gas mixes, without shutting down the equipment when switching the source mix. The hydrogen solution can be implemented both on new machines and rebuild cases.”

Reduced carbon emissions with hydrogen burners

For tissue paper manufacturers seeking an even more sustainable heating solution, reducing carbon emissions, and transitioning to cleaner energy sources, hydrogen burners play a crucial role in promoting sustainability. Paolo continues, “Unlike traditional heating methods (e.g. fossil fuel burners), hydrogen burners produce minimal carbon emissions, helping tissue paper manufacturers reduce their environmental footprint and meet sustainability goals”. Hydrogen combustion produces only water vapor as a byproduct, making it one of the cleanest forms of energy available.

A highlight on the main aspects of Hydrogen burners:

|

Features: |

Benefits: |

|

|

|

|

|

|

|

|

|

The future of Yankee Hood heating

As tissue paper manufacturers face increasing pressure to improve efficiency and reduce environmental impact, the choice of heating technology for the Yankee Hood plays a critical role. By embracing innovative solutions such as electrical heaters and hydrogen burners, manufacturers can not only enhance their production processes but also contribute to a cleaner, greener future for generations to come.

More tissue related content