Profitability improvement

In this section you can find information on Valmet's actions for improving profitability, quality costs and procurement savings.

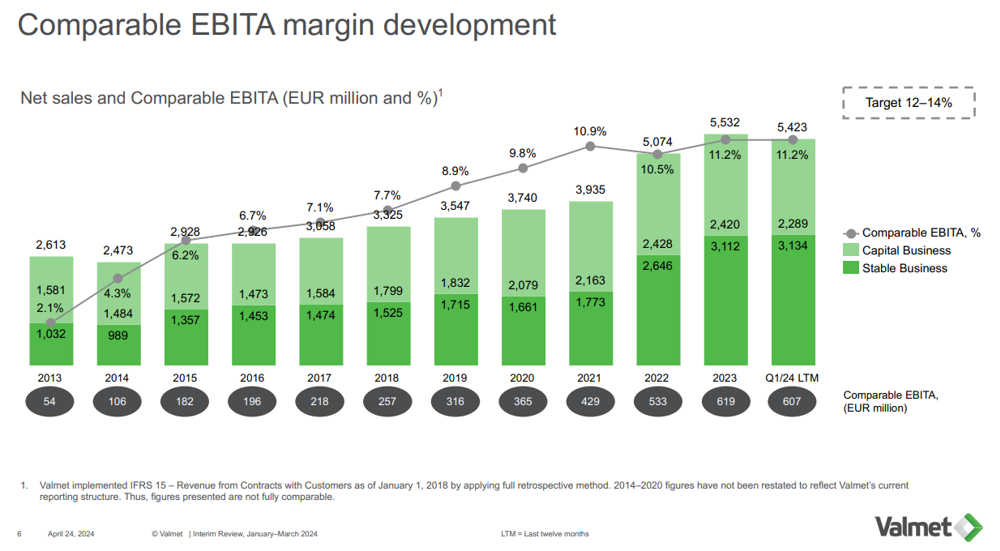

Continued focus on improving profitability

Valmet continues to focus on improving profitability through implementing its four Must-Win initiatives: ‘Customer excellence’, ‘Leader in technology and innovation’, ‘Excellence in processes’ and ‘Winning team’. Valmet targets to increase the comparable EBITA margin in all three segments (Services, Automation and Process Technologies).

Customer excellence

Valmet aims to strengthen its customer base by implementing effective sales management practices and cultivating close relationships with customers. Valmet is targeting to increase its market share in Services and Automation by growing over two times the market. In Process Technologies, Valmet aims to maintain and improve its market share.

Leader in technology and innovation

Valmet is known for its world-class technology and is always looking to bring advanced and innovative solutions to the market. Furthermore, Valmet is placing a strong emphasis on product cost competitiveness.

Excellence in processes

Valmet is continuously developing and improving its processes. Valmet aims to ensure excellent project management and project execution. Supply chain management and efficient procurement are key for Valmet. Valmet is also streamlining its processes and renewing the ERP system.

Winning team

Valmet has a strong home base in the Nordic region but has also been increasing procurement, production, and engineering resources in cost-competitive countries. The company is investing heavily in its people, particularly through the global training portfolio, which supports the execution of the must-wins.

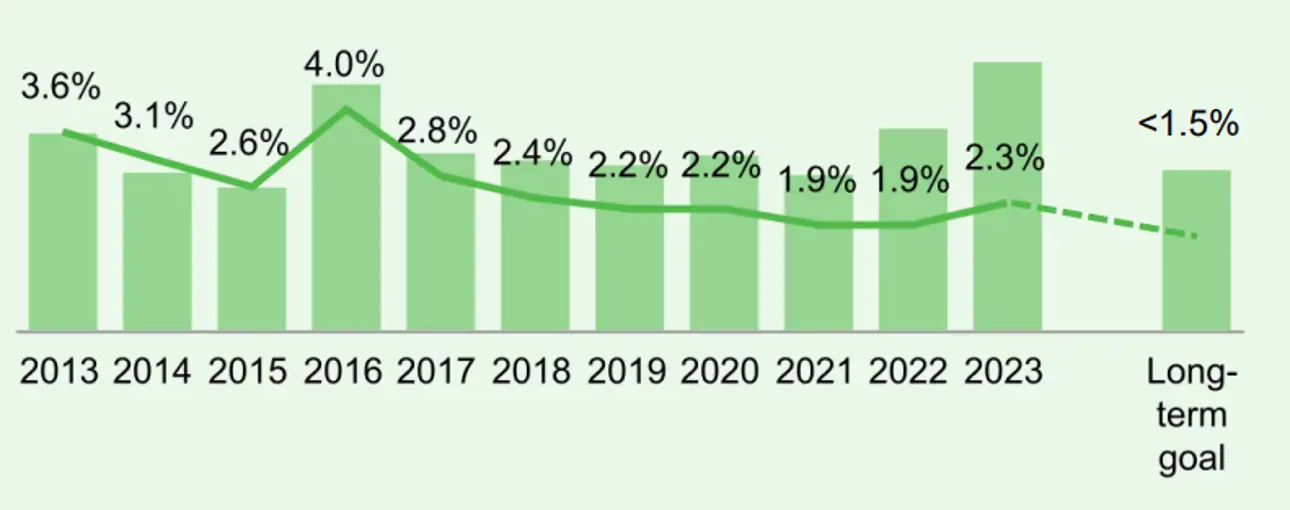

Quality costs (% of net sales)

Long-term quality costs goal <1.5% of net sales

- Adding focus on global processes and Global Management System

- Focused quality development projects related to supplier quality, quality assurance and quality control, continuous improvement, audit and risk management

Implemented procurement savings of annual direct spend

Targeting >3% of procurement savings annually

- Increasing local and cost-competitive country purchases

- Increasing design-to-cost (DTC) to create new sources for savings

- More supplier involvement through supplier relationship management

- Continuing sustainable supply chain implementation