Your partner in sustainable pulp production

Raw material and energy efficiency, combined with circularity, play an important role in more sustainable pulp production. The key is to get more from less. Today, we can already offer carbon-free pulp production, high production efficiency and solutions to produce value-adding products from pulp mill side streams.

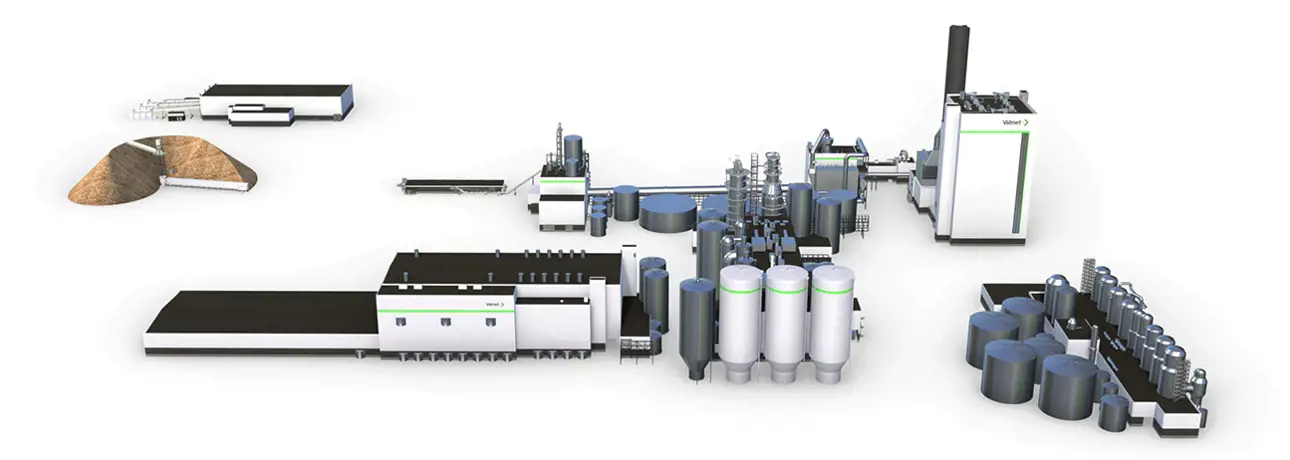

State of the art chemical pulp mill

0

Fossil fuel consumption

120%

Electricity production over own consumption

<9

GJ/adt, heat consumption

500-550

kWh/adt, power consumption

We are committed to jointly developing new solutions to meet your future sustainability needs. Together, we can create more high-quality pulp and other value-adding products with less raw material, less chemicals and zero waste – at the same time as producing renewable energy.

Our shared target is optimized performance with maximized reliability. By combining your knowledge and our expertise, we can reduce your operating costs and environmental footprint. We offer you a unique combination of our innovative process technologies, automation and services.

Getting more from less in pulp production

Global megatrends are driving toward carbon neutrality, resource efficiency and circularity, thus increasing the demand for renewable materials. Already today the modern pulp mills meet most of the sustainability goals including carbon neutrality – but we can do more to meet the future needs.

Read More

Lime kilns go fossil free

In a chemical pulp mill, the lime kiln is the only major consumer of fossil fuel – usually natural gas or fuel oil. With the latest technologies and expertise, there are now several commercially proven CO2 neutral fuel alternatives. The two main alternatives are wood powder firing and biomass gasification. It is also possible to convert existing fossil fuel kilns to use biomass as fuel.

Read More

Ensure sustainable pulp production with the right combination of services

Do you want to increase the product efficiency, optimize operational costs, improve safety, maximize value of raw materials and reduce emissions, energy and water consumption? Our global network of services professionals is committed to provide you with the right combination of services for every stage in the lifecycle to maximized reliability and optimized performance of your pulp mill.

Read More

In mill-wide optimization, one plus one makes more than two

Autonomous systems can help improve reliability, because instead of being reactive, they can provide predictive and prescriptive information for decision making. Autonomous machines can learn how to optimize and run themselves, thus improving operational performance.

READ MORE

Turning side streams to value-adding products

In modern pulp production, operating sustainably is a continuous goal – pulp producers around the world are aiming for closed circles and working to minimize waste and harness side streams. We continuously expand our offering with new solutions. These solutions turn different production side streams into new value-adding products like lignin and sulfuric acid.

READ MORE

Let's move forward together

By combining your knowledge and our expertise, we can improve your production efficiency significantly, lower your operating costs and reduce your environmental footprint by providing you the unique solutions of our innovative process technologies, automation and services.

Contact us