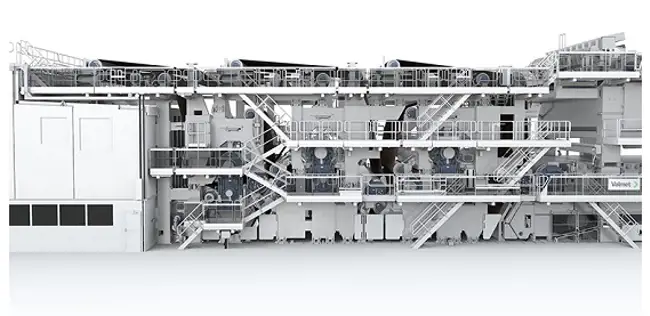

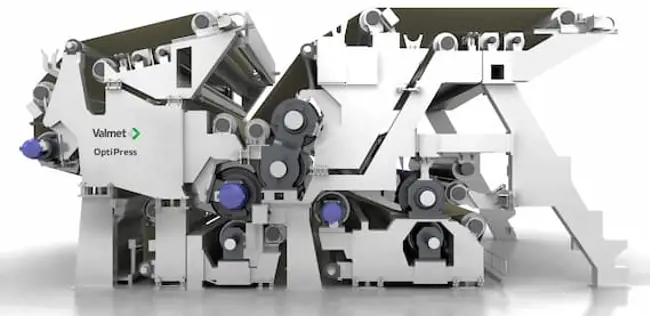

Valmet press sections

Reliable, high-performing press that ensures quality

Trend towards lower basis weights, higher speeds, lower-grade raw material, closed production cycles, and demands for further improvements in printability place special demands on press section configurations. Valmet’s press section solutions are designed to ensure the consistent levels of efficiency required for high quality and runnability.

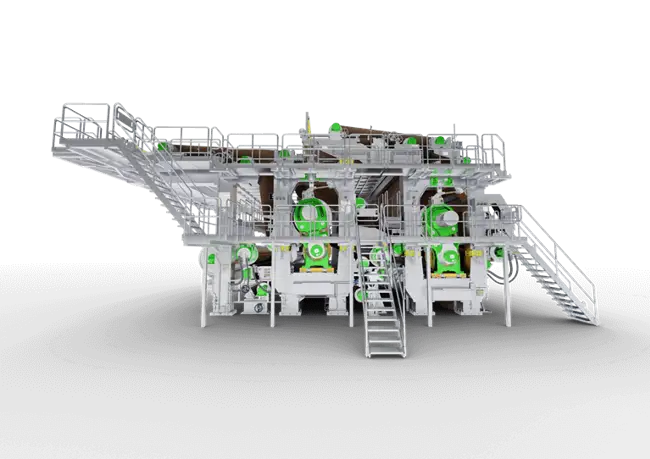

Discover Valmet press section solutions

Get to know our two press section product families: OptiPress press sections and IntelliPress press sections. Click on the links below to read and find out more of our press section solutions.

Wet pressing

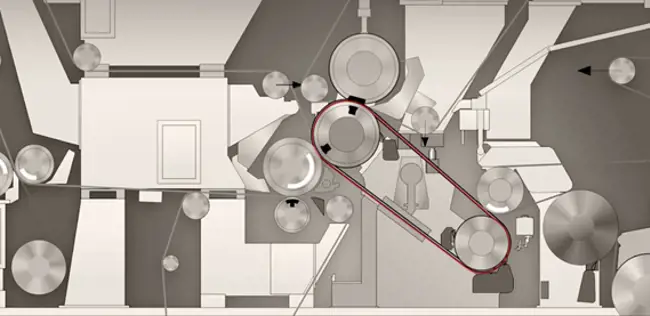

The task of the paper machine press section is to remove water, primarily through wet pressing. Wet pressing increases sheet dryness in order to ensure adequate paper machine drying capacity and to improve web runnability at the beginning of the dryer section. The press section also has a major impact on sheet surface properties such as roughness and absorption, and indirectly also on bulk.

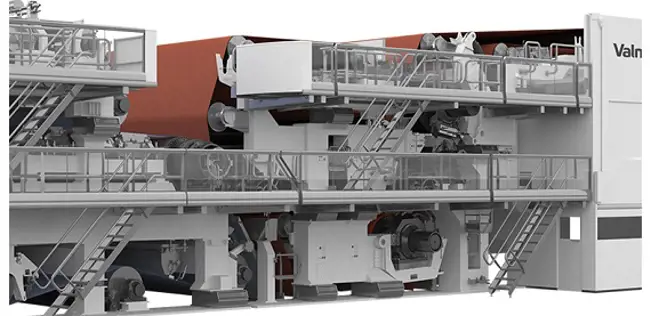

Shoe press for improved runnability and capacity increase

Shoe press technology has been used successfully in board and paper production for many years. Valmet’s SymBelt shoe press significantly improves quality and adds dewatering capacity in the press section with fewer press nips. The resulting high dryness gives high wet web strength, which is important in minimizing breaks in the open draw to the dryer section.

Want to talk to our press section experts?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact our expertsWet end pilot trials

We offer the opportunity to experiment and develop paper and board products and processes at Valmet Paper Technology Center without having to put your own production on hold. This is very cost-efficient compared to expensive tests in your own production. You can follow the activities in the trials on site or remotely through live streaming cameras.

Valmet Paper Technology Center provides the world's most comprehensive offering of testing and piloting services to paper and board manufacturers worldwide. Our pilot facilities have the entire process covered, from stock preparation to coatings and everything between, providing customers with excellent service and reliable results to support investment decisions.

Wet end rebuilds

Rebuilding a paper or board machine, or a section of it, can improve the competitiveness of your business and your processes. But where do you start? Over the years, we have gathered plenty of experience and expertise in rebuilding all kinds of machines. We asked our experts to provide tips, advice and industry insight to help you demystify the rebuild process and created a practical guide book.

Download our e-book to learn how to develop a winning rebuild concept, how to minimize rebuild related risks, and how to ensure smooth ramp up to full production.

Services and automation solutions for press sections

Explore our latest board and paper press releases

- Jan 11, 2024Valmet to supply key technology for Shandong Jin Tian He Paper’s board machine in China

- Oct 25, 2023Valmet has received a major order of multiple technologies from Liansheng Pulp & Paper in China

- Oct 4, 2023Valmet introduces a new rotating consistency measurement for pulp and paper producers

- Sep 26, 2023Valmet to supply a fine paper making line to Yueyang Forest Paper in China

- Aug 31, 2023Valmet to supply key pulp and paper technologies to Naini Papers in India

- Jul 19, 2023Valmet to supply a high-capacity winder to Gascogne Papier in France

- Jul 4, 2023Valmet to supply an OptiFlo headbox and Valmet Conical Refiners to Shree Ajit Pulp and Paper Limited in India

- May 8, 2023Valmet to rebuild ITC’s board machine in India

- Apr 25, 2023Valmet to deliver key technologies for Henan Longyuan Paper’s testliner line in China

- Mar 27, 2023Valmet to supply a new container board making line to DS Smith in Italy