Optimize the tissue machine drying process

Drying section

The drying section plays a crucial role in ensuring the production of high-quality tissue products. Understanding how the drying section works is essential for optimizing efficiency and runnability.

Explore our drying solutions

At Valmet, we specialize in providing innovative drying solutions that enhance the drying section's effectiveness. Our expertise and cutting-edge technologies can help you achieve optimal drying results while maintaining the highest standards of quality and productivity.

Key components of the drying section

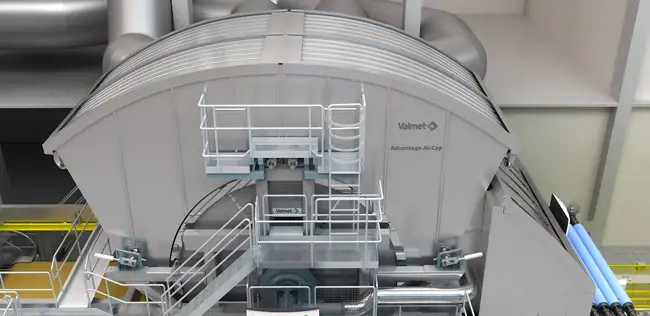

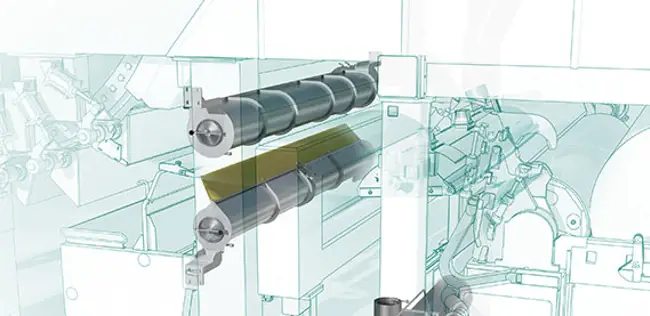

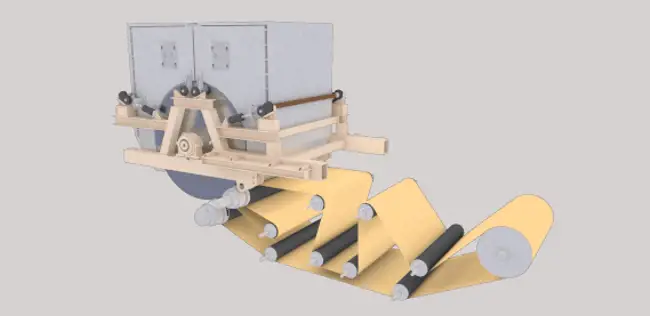

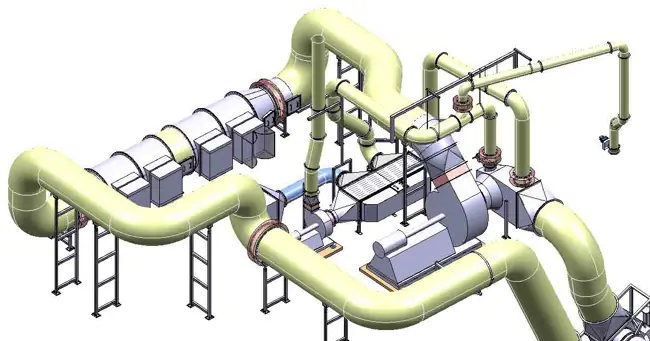

In tissue making there are several key components included in the drying section. Depending on machine type, through-air drying (TAD) and Yankee drying – together with the Yankee hood - are the major contributors to drying the tissue paper. Through-air drying involves passing hot air through the tissue web, resulting in a very high-quality tissue paper. Yankee drying, on the other hand, utilizes a large, heated cylinder to dry the tissue web as it comes into contact with the cylinder surface. The hood is an enclosed structure that partly surrounds the Yankee cylinder. It captures the moist air emitted from the drying process and directs it to the air system which in part recirculates it, minimizing energy loss and maintaining a balanced environment.

Steam and condensate systems supply steam to the Yankee cylinder for heat transfer and collect the condensate formed during the drying process. Proper steam and condensate management ensure efficient drying and prevent quality issues. The hood air system is provided with fans that circulate and exhaust the humid air coming from the hood; the system is also provided with heat exchangers that recover thermal energy from the exhaust. This aids in moisture removal and helps establish and maintain the desired drying profile for the paper web.

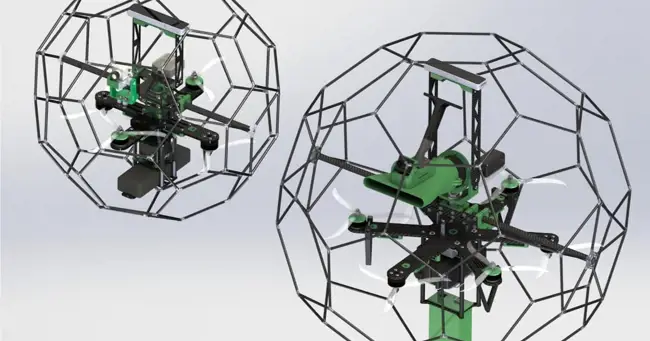

Improved efficiency and a lower environmental impact

In recent years, there have been significant innovations in drying concepts to improve efficiency and sustainability. These innovations include advanced control systems, optimized air flow management, and heat recovery solutions. By implementing these innovations, tissue machine operators can achieve higher production speeds, reduce energy consumption, and minimize environmental impact.

Explore our service offerings

Q&A section - Learn more about the drying section of a tissue paper machine

Q: What role does the drying section have in achieving desired paper properties?

A: The drying section in a tissue machine removes moisture from the paper sheet, which is crucial for achieving desired paper properties such as strength, bulk, softness, and absorbency.

Q: What are the main components involved in drying the tissue paper?

A: The main components involved in drying tissue paper are drying cylinders (or Yankee dryers), the Yankee hood, steam and condensate systems and air systems.

Q: Which factors influence drying efficiency and runnability?

A: Factors influencing drying efficiency and runnability include steam pressure, hood design, airflow distribution, paper moisture content, and Yankee dryer surface conditions.

Q: What sources of energy are used for drying the tissue paper?

A: The Yankee cylinder uses steam, whereas the Yankee hood is provided with burners that can be powered by several types of fuels (natural gas, LPG, hydrogen) as well as electrical heaters, steam or diatermic oil coils and other heat sources.

Q: What process control and automation are needed in the drying section?

A: Overall, comprehensive process control and automation systems are essential for maximizing drying efficiency, maintaining product quality, and ensuring smooth operation of the tissue machine.

Q: How to monitor and measure drying performance?

Monitoring drying performance involves measuring temperature, moisture content, airflow, paper quality, and energy consumption.