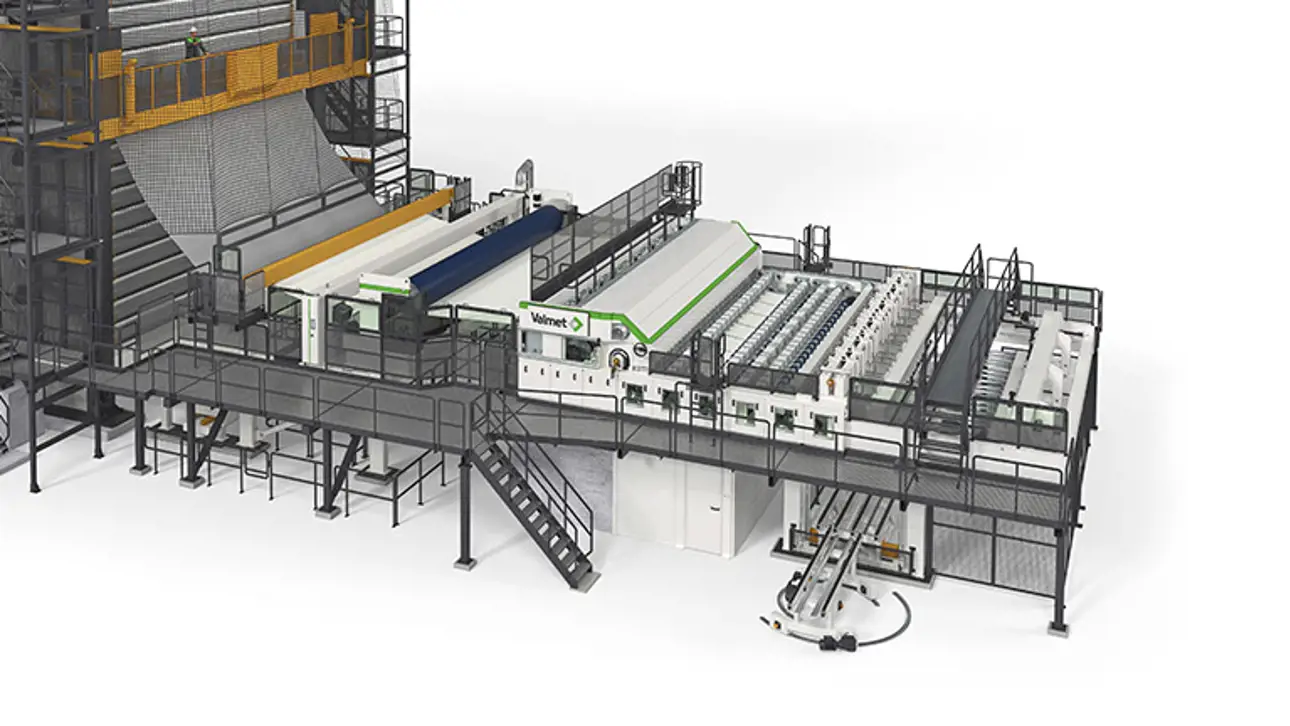

Valmet Cutter

The Valmet Cutter is suitable for all pulp types and cuts the pulp web into sheets. It can be used for cutting wrapper sheets for bale wrapping as well. The change from normal sheets to wrappers or vice versa takes place automatically in less than one minute with no effect on the drying machine speed.

User-friendliness

Fully automatic operation.

Reliable operation

High availability.

Safety

Sophisticated safty features and automatic operation.

Controlling operations

The Cutter is always provided with independent PLC logic equipment, which controls all operations of the Cutter. The manual controls are placed in a control panel and marked with distinct symbols. The local layboy control panel has an info display providing instructions to the operator and detecting possible defects. Control of the dryer pull press is connected to dryer control (DCS) system because this gives an opportunity to switch off cutter control system when sheet can be still maintained through the dryer and falling in to the dry end pulper. The Cutter always comes with a complete pneumatic equipment package and a hydraulic unit with piping and controls.

Automated change in less than a minute

The changeover from one sheet size to another, for example when running wrapper sheets, is quickly accomplished. Whenever the push-button of a desired sheet size is pressed, the cutter keeps stacking the sheets until the unfinished stack is ready. Then the reject gate is opened and the full bale table is emptied simultaneously. After this, the slitters, separating wedges, divider plates and sheet stop move to the places required by the new sheet size. The speed of the cross-cutting roll adjusts itself to correspond to the new sheet length. All these functions are fully automatic. After this, the cutter is ready to start making bales with a new sheet size at only a push of the reject gate closing-button. All this takes less then a minute.

Safety and maintenance

Attention has been paid to safety, ease of maintenance and control of the slitter and cutter assenblies. The knives are easily adjustable and the control and adjustable bearing housing systems guarantee long knife service life. For optimum safety, the cutting area is fully enclosed, preventing access. The cross-cutting roll is furnished with a noise-dampening guard. The slitter assembly and drives are also fully protected.

Our expertise is at your service

We at Valmet are committed to moving our customers performance forward and make sure you have a reliable, safe and user-friendly operation.

Contact us