Liansheng collaborates with Valmet to expand from industrial to tissue paper production

Mar 8, 2024

Liansheng Pulp and Paper, although being a relatively new player on the market, is not afraid of challenges. With a dedicated mind, driven by innovation, through product diversification and high-end product development, the paper producer is now successfully expanding from industrial paper, venturing into the world of tissue paper.

When transforming a blank canvas into a work of art, each brushstroke of color is a journey

Facing the current complex situation of the global economy and in the pulp and paper industry, Liansheng Pulp and Paper, although being a relatively new player on the market, is not afraid of challenges. With a dedicated mind, driven by innovation, through product diversification and high-end product development, the paper producer has embarked on a unique and sustainable development journey, establishing an integrated development advantage in the industry. In May 2023, Liansheng further expanded their business by starting up two Valmet tissue paper production lines, TM3 and TM4, at the Zhangzhou location. These two Valmet Advantage™ DCT200HS lines are high-speed and wide width with an annual production capacity of 120,000 tons. Further, the machines run at high stability with low energy consumption and are easy to operate. Liansheng, are now successfully expanding from industrial paper, venturing into the world of tissue paper.

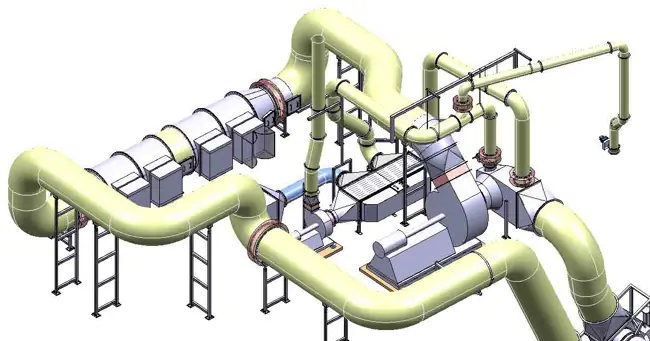

Aerial view of Liansheng Zhangzhou tissue mill

Sampo is the essence of sustainable practices

Sempo, the tissue paper brand of Liansheng, represents the true essence of integrated development in forestry, pulp, and paper, emphasizing a commitment to a circular economy.

Forest is for nature as treasure is to troves, Liansheng looks forward to presenting a green philosophy to consumers through the best equipment and stable distribution.”

Fan Lele, Sales Deputy General Manager of Tissue Paper at Liansheng Zhangzhou

According to Fan Lele, the Sales Deputy General Manager of Tissue Paper at Liansheng Zhangzhou, the main responsibility of Liansheng's integrated approach in forestry and pulp-paper production is to ensure a stable supply of raw materials. The company uses the best papermaking equipment from top global manufacturers and employs cutting-edge technology to produce tissue paper products with enhanced stability, providing consumers with products they can trust for the long term.

Based on Valmet’s advanced technology, comprehensive services offering and automation solutions, Liansheng chose Valmet as their partner. The collaboration has worked seamlessly for years, starting with the Jiaomei mill and now with the investment in the Zhangzhou mill. Together, they have successfully made a breakthrough in the of tissue paper segment, starting from scratch. Now Liansheng’s goal is to quickly strive for a leading position in a competitive market.

Liansheng's tissue paper product brand Sempo

The new mill is pushing the boundaries in the industry

The newly built production site in Zhangzhou simultaneously launched multiple production lines for mechanical pulping, fine paper, folding boxboard (FBB) and tissue. The latter, being a new area for the company was coupled with a brand-new operational team. One can imagine the difficulties they faced by starting up two tissue production lines at the same time, and continuously increasing the speed after start-up to produce high quality paper at stable production. It was a huge accomplishment and during this whole journey they have had high expectations and been willing to take on the challenges. As a response to the current market demands for tissue paper in terms of quality, flexibility, and low basis weight Liansheng uses two Valmet Advantage DCT200HS tissue production lines to produce low-grammage (12.5-14g) with high-bulk.

“To produce low grammage with high crepe ratio is actually a great challenge for tissue paper.”

Zhang Hua, Vice President of Liansheng Pulp and Paper, Zhangpu.

Both teams worked together, one step at a time to achieve excellent results

“Time was tight, tasks were heavy, and the difficulties were many.” This is how Ji Yongwei, Project Manager at Valmet summarizes this project. With a joint effort of both teams two Valmet Advantage DCT200HS tissue machines were successfully started up and put into operation in only 13 days. The collaboration between the two companies was crucial for the success of the project.

“Valmet’s technical team is truly knowledgeable. Their foreign experts are always willing to listen to their customers’ needs and suggestions, and quickly give support. This is one of the important reasons why we always choose and trust Valmet,” says Liu Shichao, project manager of Liansheng Pulp and Paper Zhangzhou Tissue Paper Project, comments.

Image from the Liansheng Zhangzhou TM3 and TM4 start-up

After TM3 and TM4 started up, they quickly accelerated to 1800 meters per minute. The paper consistently maintained high quality, with notable advantages in terms of uniformity. Two weeks later, the paper products exceeded Liansheng’s expectations. At the same time, the production capacity is still steadily increasing with the joint efforts of both parties.

“During these past months Valmet’s Advantage DCT200HS tissue machines have been running very stably and are easy to operate. This is particularly valuable for Liansheng’s new factory start-up and our new employees. The quality, operating efficiency, and energy consumption of low-grammage and high bulk tissue paper are all in line with expectations,” says Zhang Hua, Vice President of Liansheng Pulp and Paper Zhangzhou mill Tissue Paper

Liansheng operation team and Valmet technology team

So how did Valmet help Liansheng achieve their requirements of paper quality, runnability, stability and low basis weight? The Liansheng team believes it is because of the following aspects:

- Valmet’s Advantage ViscoNip press design is highly successful, with high adaptability and reduced difficulty in selecting the felt types. The performance of the soft shoe press is stable, the technology is mature and easy to operate. In addition, its unique pressing technology results in low energy consumption. Valmet’s tissue machine is 0.2 tons less than other models in the same factory. The energy consumption data of the entire line is also at a relatively good level in the industry.

- The material of Valmet’s Yankee cylinder is made of steel, which has good thermal conductivity and low energy consumption. The surface of the Yankee cylinder is sprayed with Valmet Infinikote Yankee metallizing which is of great help to operate the machine and produce a high quality tissue product.

- The Valmet specialized IQ scanning designed for tissue paper machines employs positive pressure air dust prevention, a built-in water tank with unique design, and excellent sealing. This ensures outstanding performance and low maintenance even in conditions with a high amount of paper lint when producing toilet paper grades. Additionally, the high level of intelligence monitors the production line, promptly alerting to quality issues, thereby improving production efficiency.

- The Advantage DCT200HS is more advanced than other tissue machines encountered before, both in terms of process and equipment structure. Its convenience of maintenance is unmatched in the industry, allowing for easy adjustments in production and maintenance according to the tissue makers need.

The Advantage DCT200HS meets Liansheng's requirements for bulk and high creping efficiency. Zhang Hua proudly states:

When producing 13 grams paper, other models in the market may have to achieve a creping rate of 30% or even 32%, but we at Liansheng can achieve 26%"

Navigating by the direction of the heart and building dreams for the future

Liansheng chose the Valmet IntelliTissue production line and purchased additional head boxes for the low-grammage, high-crepe ratio products required in the second phase of the project. They praise the stable operation and high reliability of machine, as well as the high level of expertise in the head box, and is very much looking forward to the uniformity of the paper produced.

When looking to the future, Zhang Hua confidently states, “The future of this industry is definitely a competition for the entire supply volume, not just a competition for a single product. With our Liansheng mill, we should now, and in the future, be more competitive in the field of tissue paper.”

Finally, he once again praised Valmet’s performance in Liansheng.

“I also understand that Valmet’s equipment has performed well not only in our tissue paper production, but also in our Liansheng FBB and fine paper machines. This is a proof of Valmet’s capacity in the entire paper industry,” concludes Zhang Hua.

Liansheng Pulp and Paper Zhangzhou mill TM3, TM4 Production Supervisor Zhou Qiuwei (left) and Valmet Project Manager Ji Yongwei (right).

About Liansheng Pulp and Paper (Zhangzhou) Co., Ltd.

Liansheng Pulp and Paper (Zhangzhou) Co., Ltd. was established on April 1, 2020, located in Zhangpu County, Zhangzhou City, Fujian Province, with a land area of approximately 4,600 acres. The project plans to produce 3.9 million tons of FBB, fine paper, and tissue paper annually, with an annual output value of over 20 billion yuan. The mill is equipped with advanced pulp and papermaking equipment and will form a modern large-scale papermaking plant integrating “pulp and paper” after completion. It is also equipped with large-scale sewage treatment plants, thermal power plants, port terminals, and other projects.

Liansheng Zhangzhou mill tissue paper production line TM4.

More tissue news