Adaptability ensures excellence

Dec 13, 2023

Jingxing Paper recently started up their new TM 5 and TM 6 tissue production lines in Zhejiang province, China. The company relied on Valmet technology and expertise to ensure their production can adapt to rapidly changing customer demands.

Zhejiang Jingxing Paper stands proudly on the picturesque Hangjiahu plain in China, where the majestic Qiantang River meanders, and an ancient road stretches into the distance. Despite the historic location, the company is a modern enterprise and in response to the ever-increasing demand for high-quality tissue products, it has been adapting its business accordingly. As a result, in 2022, Jingxing Paper proudly introduced two cutting-edge new tissue machines, TM 5 and TM 6, with an annual production of 120,000 tonnes. These state-of-the-art lines boast high capacity, low energy consumption, remarkable speed and an impressive width capability.

Lu Bin, Deputy General Manager of the Household Paper Division, Zhejiang Jingxing Paper Joint Stock Co., Ltd.

Carefully chosen technology

“Our project was initially focused on the large tissue machine. At that time, we had lengthy discussions about the technical solutions for the shoe press and traditional press suction roll,” says Lu Bin, Deputy General Manager of the Household Paper Division, Zhejiang Jingxing Paper Joint Stock Co., Ltd. “In the end, we chose Valmet’s shoe press, the Advantage™ ViscoNip® press partly because of its mature technology. But we also considered the energy-saving benefits of the shoe press for the overall operation.”

We decided to cooperate with Valmet on this project because they have a good service team and strong equipment delivery capabilities, with a long history of technological innovation.”

The company also chose a Valmet rewinder for the machine. “As core supporting equipment for household tissue paper, the rewinder is crucial. We expect that Valmet’s rewinder and tissue machine will work very well together and ensure the quality of our products,” says Li Liubai, Deputy Chief Engineer, Zhejiang Jingxing Paper Joint Stock Co., Ltd.

Zhejiang Jingxing Paper’s and Valmet’s technical team.

Extensive automation package

Jingxing TM 5 and TM 6 are equipped with an extensive automation package, including a Valmet DNA distributed control system (DCS) with built-in machine controls (MCS), advanced process controls (APC) and a Valmet IQ quality control system (QCS).

“Valmet DNA provided the entire system in a single unified platform, ensuring the sharing of data flows throughout the system and greatly improving the efficiency of system integration. A modular design and visual management make operations easier and more convenient.” Li Liubai, Deputy Chief Engineer of Zhejiang Jingxing Paper Joint Stock Co., Ltd.

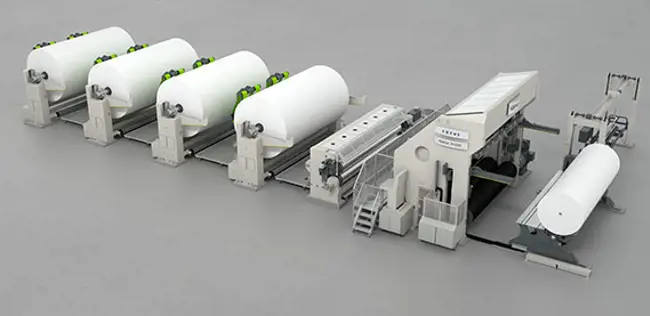

One of the Valmet Advantage DCT 200+ tissue machines.

Reaching every planned milestone

Despite the challenges in the industry over the last few years, close cooperation between Jingxing Paper and Valmet led to successful start-ups of both TM 5 and TM 6. Together, the projects included two Valmet Advantage DCT200+ tissue machines, as well as three Valmet Focus™ Rewinders provided by Valmet. Li Liubai is extremely satisfied with this achievement. “During project execution, the pandemic severely affected design communication, equipment delivery, personnel deployment and civil construction. To overcome these challenges, we established effective communication mechanisms and forward-looking planning arrangements with Valmet. Both parties worked to promptly address any potential impacts, ensuring that the project progressed according to the planned milestones.”

We have complete confidence in the Valmet team, and they consistently demonstrate their expertise.

Adapting to evolving customer demands

Jingxing Paper is relentless in their pursuit of improvement, and since the start-up, they have continued to work closely together with Valmet to help them fine-tune both machines further to enhance product quality and production levels, and to minimize energy consumption. To meet the evolving demands of their downstream customers, Jingxing Paper also needs to be able to adjust and optimize various product types with crepe ratios ranging from 18 to 35 percent, and basis weights between 10.5 g and 42 g. “When we needed support with frequent changes in product grades, Valmet urgently dispatched an experienced team to carry out adjustment and optimization for the products,” says Li Liubai.

One of the Valmet Focus™ Rewinders.

A bright and prosperous future

This is the first time that these rewinders have been installed in China by Valmet. One of the benefits of Valmet’s patented Focus technology is that it effectively reduces the loss of bulk thickness. Their advanced design concept enables the new machines to be adapted to the mill’s production capacity and to different quality requirements for finished products, making upgrades easy. Furthermore, thanks to the Valmet Advantage ViscoNip press with its innovative “soft shoe press” technology and a double-layer headbox, the Advantage DCT200+ tissue machine has consistently delivered outstanding performance, with significant energy-savings and superior paper uniformity, surpassing Jinxing’s other machines.

Zhejiang Jingxing Paper Joint Stock Co., Ltd.

The operational efficiency and output quality of the paper machines and winders have met our expectations.

Based on the excellent results so far results, Jingxing Paper is looking forward to a bright and prosperous future for their TM 5 and TM 6 machines.

Text Silvia Xi