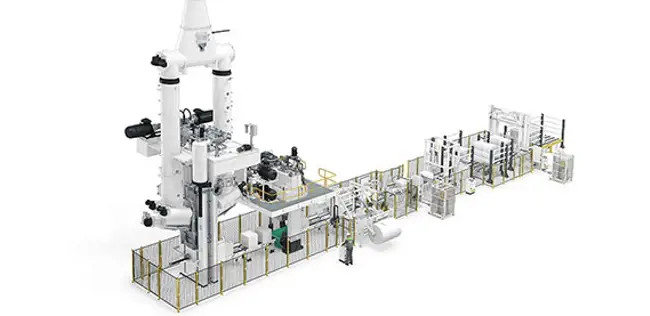

Valmet Baling

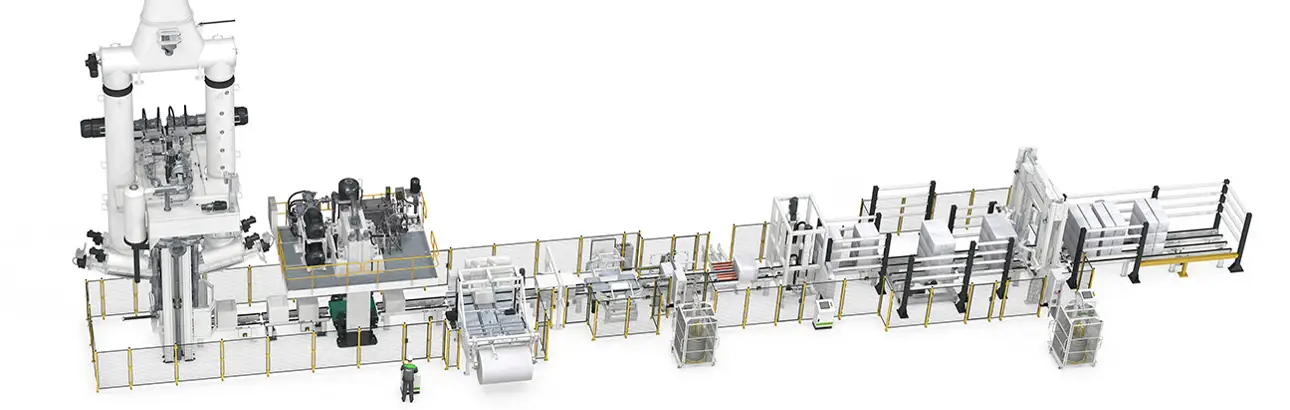

Valmet Baling Line offers the most sophisticated technology of its kind in the world for baling operations – complete baling line solutions with an optimized combination of highly reliable machines, sophisticated control system and heavy-duty conveyors to match each customer’s specific line requirements. Our well-proven technology provides a combination of high capacity and high availability that meets exacting demands for reliability and productivity. Valmet's baling machines have a peak capacity of up to 300 bales per hour. This in combination with proven high availability guarantees world-leading production rates.

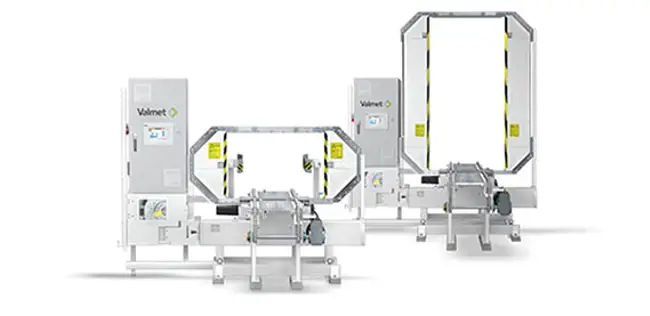

Safe

The installation is devided into safety zones. If anyone enters a safety zone, all power sources are interrupted which ensures highest possible safety levels for all employees.

Smart

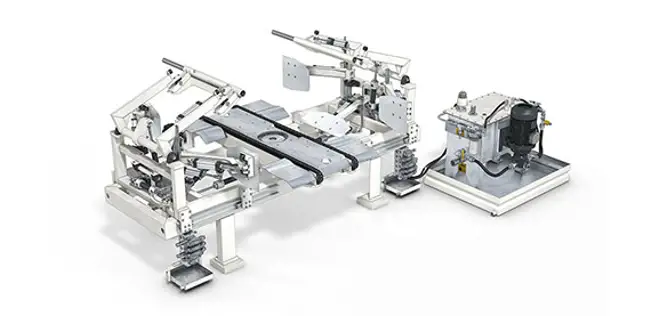

Each individual bale, bale set and bale unit is tracked throughout the line. Using absolute bale position tracking to ensure exceptionally reliable key data on production and quality, the system enhances efficiency, logistics and quality management.

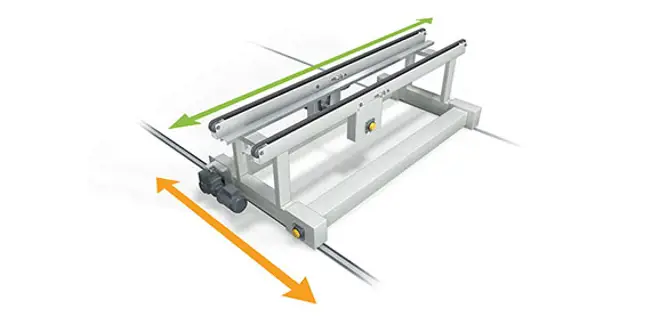

Efficient

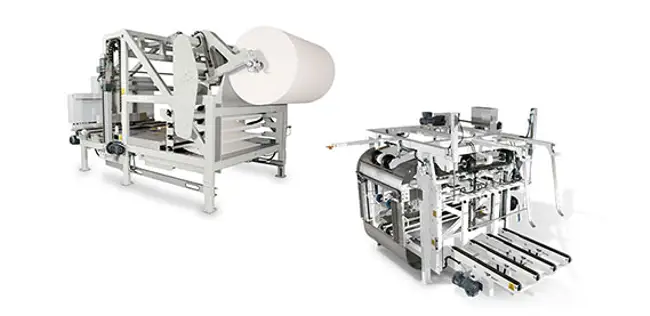

Our machines are delivered as ready-to-use units designed for fast installation and start-up. Efficient everyday operation is ensured by the superior control system, featureing PLC control equipment, which is operated and monitored via a touch-screen with an easy-to-use graphic interface.

User-friendly

All units are operator-controlled via a user-friendly touch screen panel, featuring a user interface with simple guidance for fast and easy operations and maximized production uptime. Machine status, failure indication and auto start possibilities are available for each main machine.

Valmet Bale Quality System

The Bale quality system (BQS) is a supervisory tool designed to keep track of production data and quality parameters for bale handling. BQS is a unique system that tracks each individual bale, bale set and bale unit throughout the production line. The system uses absolute bale position tracking to ensure exceptional reliability of key data.

Continous success by close collaboration and the right combination of services for every stage of the lifecycle

To maintain the competitiveness of your baling processes and to develop them throughout the lifecycle. We provide a wide range of solutions for upgrade and improve your baling equipment, processes and machinery. The scope is always based on your specific needs and the solutions are tailored to maximize the performance of your specific installation.

Our services team support and guide you in finding cost effcient solutions to get the most out of your baling processes and equipment. We offer various forms of services and advanced diagnostics.

A Service Agreement offers close collaboration to reach agreed targets, the scope is always tailored to your needs to ensure reliability, quality and increased machine equipment, electrical components and automation systems lifetime.

Process upgrades for baling lines

Remote support 24/7

Typically, our customers utilize the services of a Performance Center after new machine installations, rebuilds or through continuous service agreements. By using Valmet’s experts for problem-solving and process development, you can better allocate your own mill’s or plant’s resources for running the daily operations.

- Industrial Internet applications as a service

- On-demand expert support

- Remote monitoring and optimization

Our expertise is at your service

We at Valmet are committed to moving our customers performance forward and ensure smooth, disruption-free operation, supporting you all the way.

Contact us