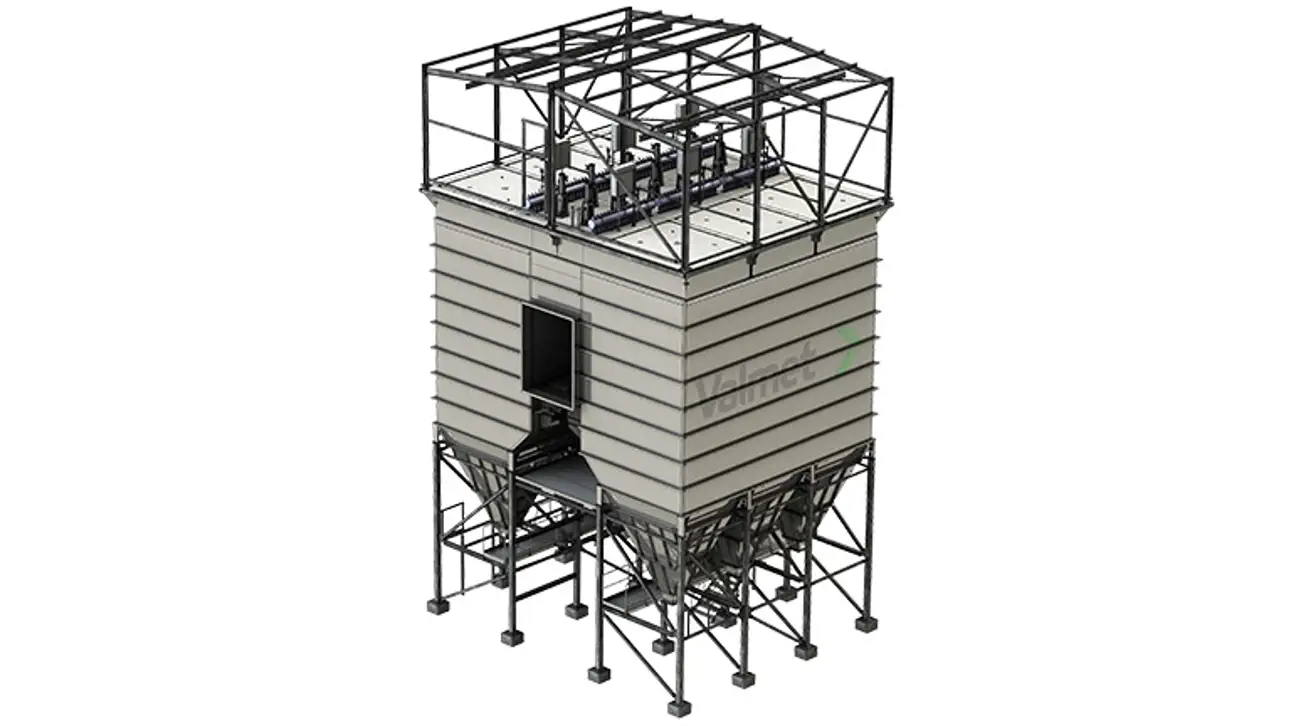

Bag House Filter

With tightening emission regulations, effective removal of dust particles and other pollutants from flue gases is a must for today’s power plants and industrial sector. Valmet Bag House Filter is designed for an effective particulate capture when you need to reach levels well below 2 mg/Nm3

Effective removal of dust particles from combustion flue gases

Typical emission level after the filtration < 1-2 mg/Nm3

Maintenance possible during 100% load

Control fully integrated into a plant DCS system

Additive injection for gaseous pollutant capture

In addition to effectively removing dust particles, Valmet Bag House Filter can be used for capturing harmful gas components, too. Acid gases can be reduced using hydrated lime or sodium bicarbonate injection, while dioxins, furans and gaseous heavy metals are captured with activated carbon injection.

To ensure the best possible operation with additive injections, the design of the baghouse filter is based on Computational Fluid Dynamics (CFD) modeling.

Conditioned Dry Sorption provides high performance

If very efficient emission capture is needed, the bag house filter can be equipped with additive recirculation and conditioning that makes the process well suitable also for waste firing. High recirculation rate is applied to improve mixing between the pollutants and flue gas. Water is added among the recirculating hydrated lime to reach the most optimal temperature and effective reactions. With this technology, the latest requirements by authorities can be easily reached.

Our expertise is at your service

Our focus is to bring your performance forward. Our expertise in sustainable energy production and emission control is at your disposal. Get in touch with our specialists through your local Valmet office, or the link below.

Contact us