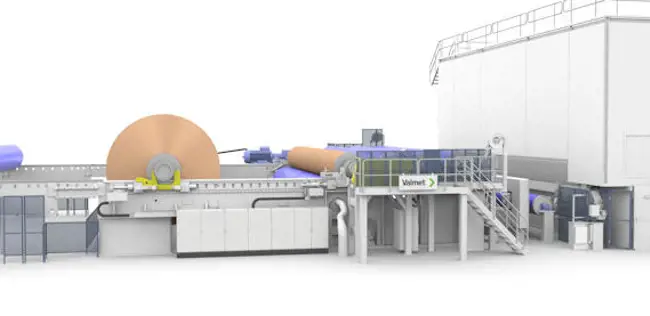

Reel improvements for board and paper making

Customized solutions to ensure better operational reliability and provide a good return on your investment

Reel improvement solutions help you to ensure that your reeling is performing at the highest possible level. With the customized solutions you will improve paper quality, solve runnability problems and ensure better operational reliability. You can also expect measurable results, a good return on your investment and cost-effectiveness.

Improve paper quality

Solve runnability issues

Better operational reliability

Unwanted unwinding of parent roll with surface binding

A surface binding device prevents unwanted loosening/unwinding of the parent roll after turn-up and during transportation for further processing. TailGrip glue, developed for this specific application, is sprayed onto the sheet edges right before turn-up. The sheet tail is then attached to the parent roll surface. TailGrip 1 and 2 are ethylene-vinyl acetate (EVA) based glues.

This process enhances operator safety by reducing roll slabbing and paper clean-up, keeping paper layers tight, and preventing loosening as the roll decelerates. This results in improved machine efficiency and less waste.”

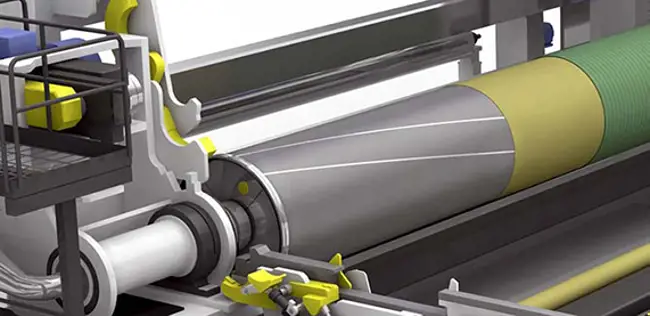

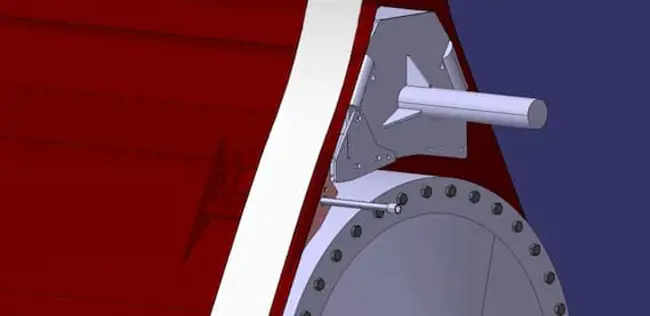

Upgrade reel loading to hydraulic

Experiencing reeling defects with your pneumatic pope reel? Consider upgrading to hydraulic for improved efficiency and reliability. This method offers controlled parameters and adjustable loading curves for optimal roll structure. Updated safety features lead to better roll quality, less waste, fewer defects, and a payback time typically under a year.

Change of parent roll quickly and cleanly with Valmet WaterJet Turn-up Device

The Valmet Water Jet Turn-up Device is a complete package that includes controls, user support, and a preventive maintenance program. This device ensures consistent, fast, and clean parent roll changes. An exceptional start to the parent roll leads to reduced bottom waste, which in turn increases productivity.

It is suitable for:

• LWC

• SC

• Newsprint

• Coated WF

• Uncoated WF

• Containerboard

• Cartonboard

Do you want to know more about process upgrades?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact usReel Safety Upgrades

If you have pre-2006 reels and unwinds and aim to enhance mill safety, we can help. We offer upgrades to meet current European directives (EC-Declaration of Conformity provided, no CE marking). This not only eliminates workplace hazards but can also lower insurance costs. Upgrades typically include safety fences/gates, mats, safety dimension modifications, and the replacement of manual operations with automatic, interlocked ones.

Related pages