Coating and Sizing improvements for board and paper making

Customized solutions to ensure better operational reliability and provide a good return on your investment

Coating and sizing improvement solutions help you to ensure that your sizing and coating sections are performing at the highest possible level. With the customized solutions you will improve paper quality, solve runability problems and ensure better operational reliability. You can also expect measurable results, a good return on your investment and cost-effectiveness.

Improve paper quality

Improve operational runability

Good return on investment

Improved drying capacity and decrease energy consumption

Upgrade of existing air dryer nozzles to high performance Valmet Air Dryer Nozzles improves the drying capacity. Using efficient air nozzles not only improves drying capacity, but also decreases energy consumption. Valmet uses nozzles with a higher heat transfer coefficient to take more energy from the impingement air. This results in less energy losses to the exhaust air and an increase in the amount of energy transferred to the sheet. Both features increase the dryer’s energy efficiency.

Upgrading your sizing and coating section

With a well-functioning sizing section, you make sure that the paper has increased strength and stiffness, prevention of dusting and reduces absorption of ink/coating colour. Coupled with a proporly working coating section you will add good printability and surface properties to the product.

We are market leaders in sizing and coating and can offer different solutions and products to upgrade your equipment. Everything from film applicator beam upgrade, safety upgrades, nip load control, automation solutions, coating beams to web break improvements, consumables and vibration dampers.

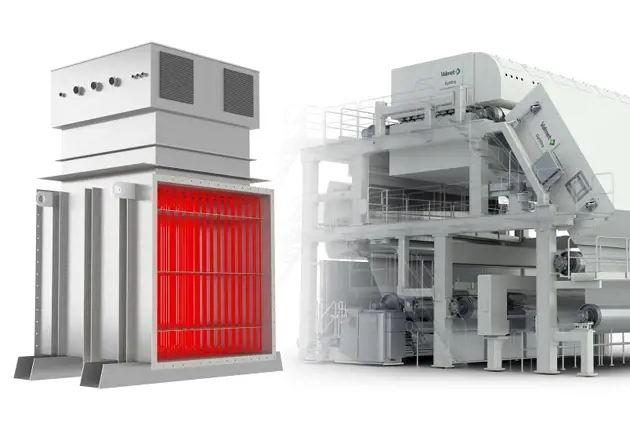

How to replace gas with electricity in coating air drying?

Many paper producers are looking for ways to eliminate the use of fossil fuels in their production. CO2-free coating drying is enabled with an electric heater which at the same time can save energy. When replacing a gas burner with electric heating in air dryer and optimizing the process, energy savings are typically 10-20% compared to before.

Do you want to reduce and optimize energy consumption?

The purpose of the coating drying audit is to clarify operation parameters of your dryers, reduce and optimize energy consumption and improve efficiency of the drying process. A Valmet expert will measure and clarify the operational values and check the mechanical conditions. This will enable optimum function of dryers. The report will contain energy saving potential with prioritized recommendations and create a solid base for future actions and investments.

| Steps | Actions | Solutions | Results |

| 1 | Evaluate where you are | Valmet Quick Scans and analyses | Best operating parameters and a foundation for furute saving projects |

| 2 | Optimize performance | Maintenance and repairs | Best performance with the present equipment |

| 3 | Update machinery | Upgrades | Upgraded equipment performance |

| 4 | Take performance and efficiency to the new level | New technologies | Significant improvements with viable payback times |

Do you want to know more about the electrification of air dryers?

We have answered frequently asked questions about replacing gas with electricity and infra-red dryers with air dryers.

Check the Q&A

Do you want to know more about process upgrades?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact usRelated pages