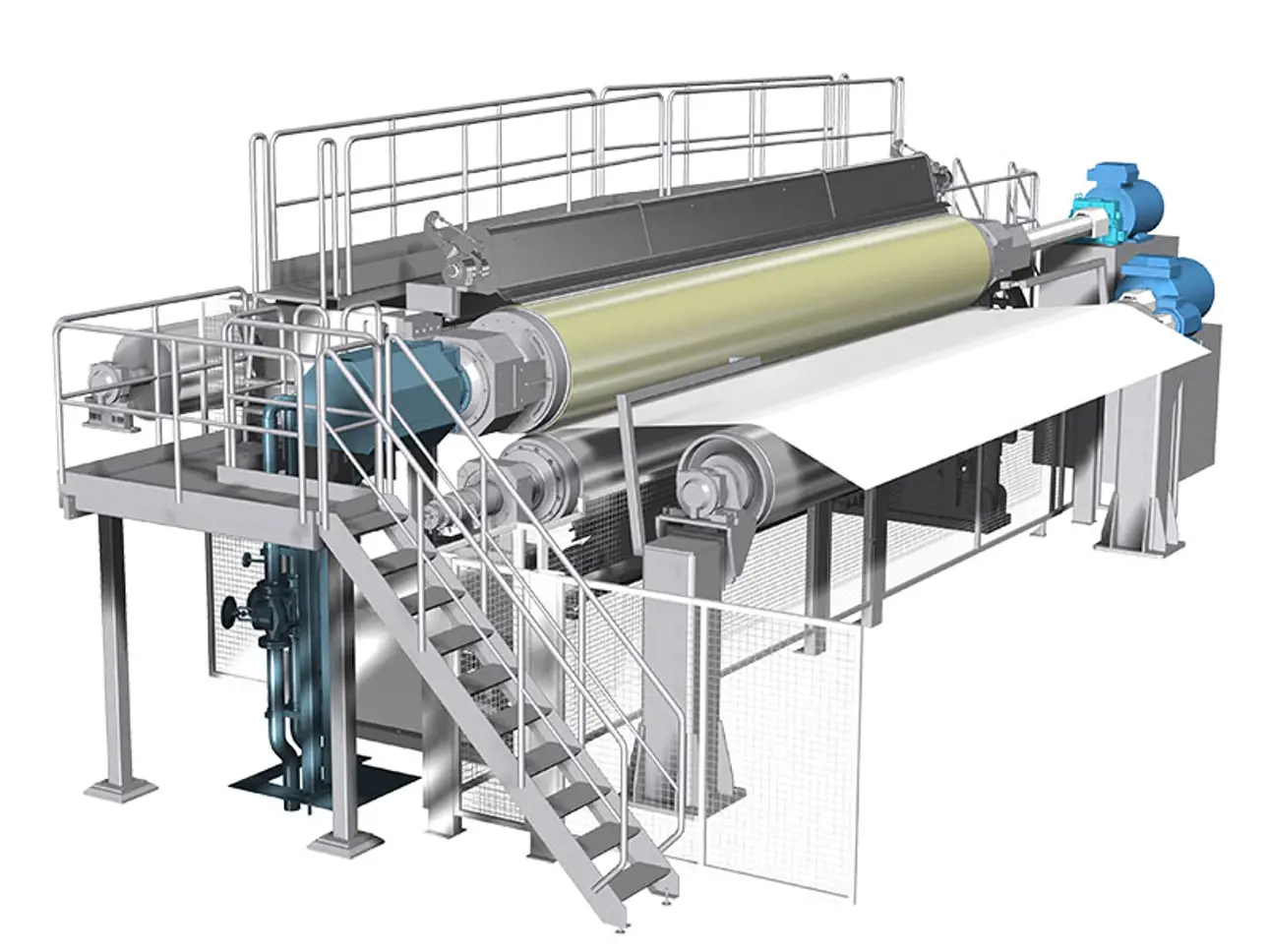

Calender improvements for board and paper making

Customized solutions to ensure better operational reliability and provide a good return on your investment

Calender improvement solutions help you to ensure that your calendering section is performing at the highest possible level. With the customized solutions you will improve paper quality, solve runnability problems and ensure better operational reliability. You can also expect measurable results, a good return on your investment and cost-effectiveness.

Improve paper quality

Ensure operational reliability

Improve cost-effectiveness

New calendering solutions are developed all the time

New solutions can be utilized in machine rebuilds and improvements to enhance the capacity and performance of old calenders. Condition tests and audits are effective ways to evaluate calender performance and identify potential issues. Based on the results and findings from these audits, a more extensive rebuild or improvement may be proposed. Calender improvements are often highly customized. Most improvement initiatives originate from customer issues, and solutions are developed based on their specific requirements. Valmet boasts excellent pilot facilities in Järvenpää, where calendering solutions can be tested, particularly in the case of quality-related upgrades.

Do you want to know more about process upgrades?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

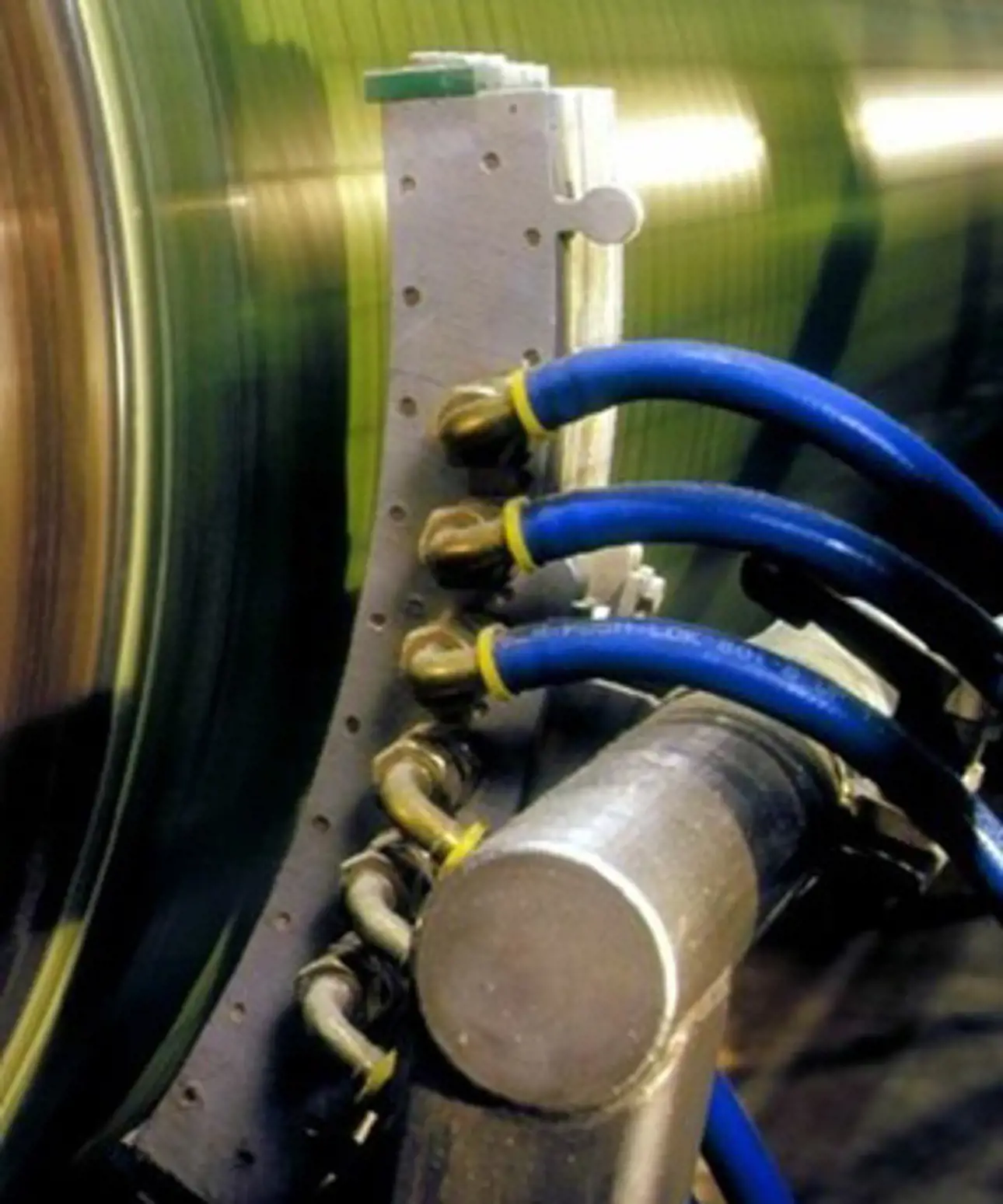

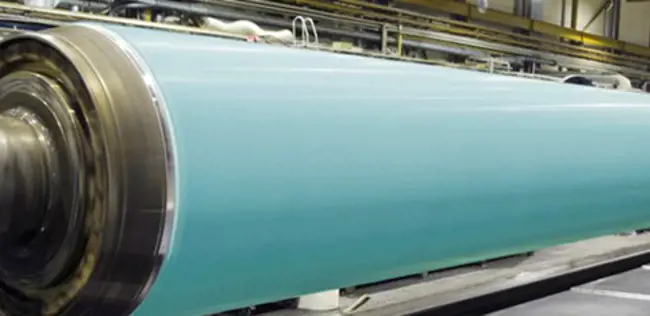

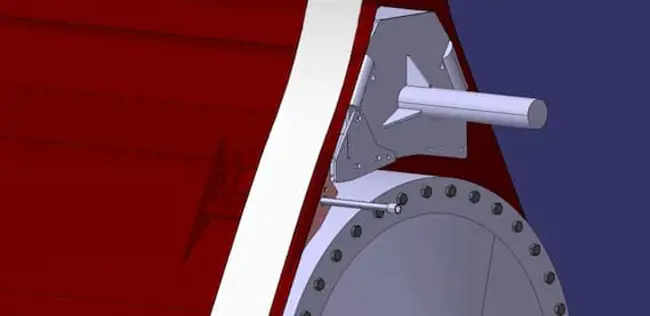

Contact usValmet Edge Cooling Device for soft roll

Edge cooling is provided for the end areas of the soft roll and is cooled with air jet nozzles. The mill air is filtered and used as cooling air. You can adjust the edge cooling width manually. Edge cooling protects the edge areas of the soft roll cover outside of the web from overheating. The roll surface temperature in the edge areas is monitored with IR sensors. By using IR sensors, the cooling can be activated only when it is needed.