Air system improvements for board and paper making

Customized solutions to ensure better operational reliability and provide a good return on your investment

Air systems improvements help you to ensure that your air systems are performing at the highest possible level. With the customized solutions you will improve paper quality, solve runnability problems and ensure better operational reliability. You can also expect measurable results, a good return on your investment and cost-effectiveness.

Improve paper quality

Solve runnability problems

Better operational reliability

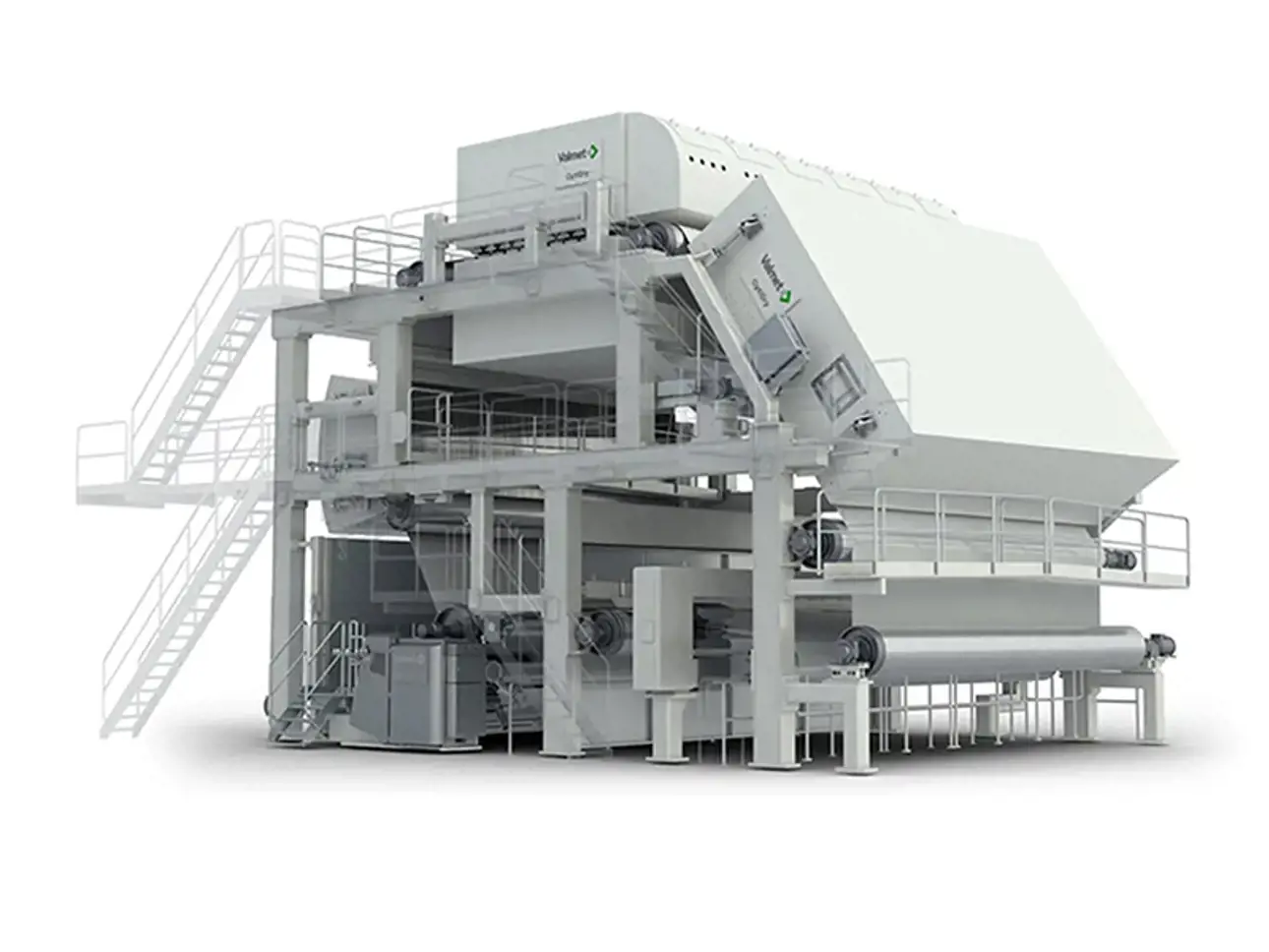

Hood Fold-Up Wall

The hood fold-up wall is a good option if your existing hood is in poor mechanical condition and needs to be improved, if you have special requirements for the drying section due to the cylinders being located at three levels, or if you would like to improve safety and working conditions. The fold-up wall has a heat-resistant internal surface, the frames and parts inside the wall are made of aluminum, and it has replaceable windows of polycarbonate. It allows for quicker and safer dryer section maintenance.

Do you want to know more about process upgrades?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

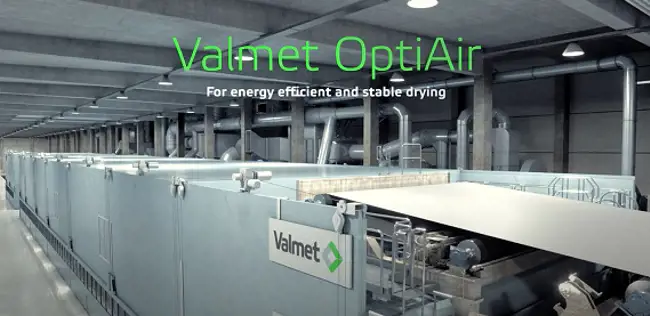

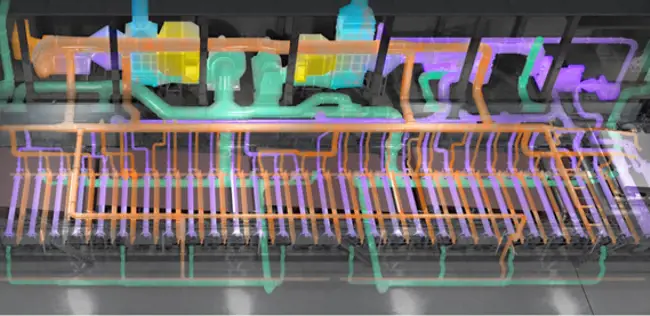

Contact usHood ventilation upgrade

Do you have challenges with condensation in dryer section construction, or hot and humid air leaking from the hood into the machine hall? The main solution is often increasing exhaust air capacity. The hood ventilation upgrades are always tailor-made to your needs. We can offer solutions like exhaust air capacity increase, hood air balance XT-control, pocket ventilation improvement, or hood construction renewal.

Heat recovery upgrades

Need to boost your air system capacity or aim for higher process temperatures? Changes in process conditions or incorrect material selection may have corroded your system. OptiAir’s heat exchangers, compatible with other brands, have a proven track record worldwide. Renewing your heat recovery system can lead to significant savings in steam consumption and costs.

Related pages