Navigating the challenge: Operating in a water-scarce landscape

Sep 21, 2023

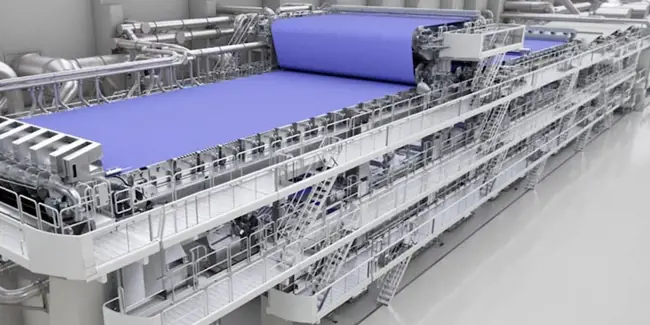

Located in an area where saving water is an ever-present concern tissue producer Faderco is examining strategies, technologies, and innovative approaches to lower and optimize their water consumption.

Access to freshwater near Faderco’s tissue mills and its subsidiary company WARAK in Algeria is increasingly strained by the phenomena of high temperatures, insufficient rainfalls and declining levels of water in deep wells and dams. As a response to this Faderco has taken several initiatives at their mill. This article delves into those actions and in a conversation with Valmet they share how they navigate the challenges of water scarcity.

Created a unique position within the company

When starting up the first mill in 2015 availability of water was not a limitation. But over time and with the project of the second mill it became evident that the region was heading toward declining levels. To address this pressing concern Faderco decided to create a position in their organization solely focusing on water management.

Rafik Khelifa, Production Site Manager, “For us water is considered a raw material. We have long fibers, short fibers and we have water. Water is very important, and we need to manage it carefully. Therefore, we decided to create this unique position. Today the water manager has his own team to follow the water input and output.”

Dramatically low levels

With dramatically low levels in the deep-water wells, the mill is forced to keep the water consumption down. They are constantly working on ways to close the water loop and to reuse as much as possible of the treated wastewater from the effluent treatment plant.

The best solution for the mill would be to run without water”

says Billel Boulenouar, Project Manager at Warak, with a wishful expression. “Unfortunately, that is not the reality!”

The biggest struggle with restricting the freshwater use is to do so without impacting the process negatively. At their first mill they tried to close the water circuit completely, consequently increasing the chemical usage. Eventually they saw paper quality variations and a negative impact on the runnability. At this point they were forced to open the system and discharge the water with unwanted substances before they could start over again with new freshwater. Ideal would be to have some sort of kidney function to handle these particles to be able to close the loop for an even longer period of time. Hearing about the added chemicals, we are curious to understand if this impacts the overall sustainability goals for the company. According to the team on site, increasing chemical usage is not an ideal situation, however no additional waste has been reported.

Utilizing the rejected water

Today they have reached a point where they are trying to recycle as much as possible of the rejected water. As a result, the amount of freshwater added into the process is relatively small. In addition, Faderco is trying to capture water from the process and reduce the consumption in any way they can. Some methods are to recover sealing water and to close cooling water circuits.

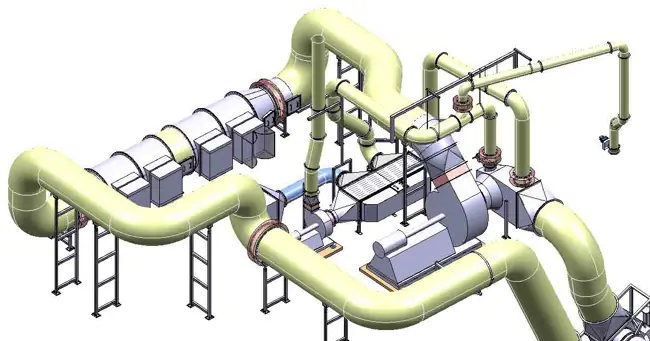

The effluent treatment plant at Faderco's tissue mill in Algeria

How about the excess water that can’t be returned back into the process, how can that be handled? “We are using it for the lawn and the trees around the mill to create a green area. We also use it for cleaning our facilities. As you can hear, it contributes to create a nice environment around here,” says Khelifa with a laughter.

The accumulated reject has an opportunity to be utilized as valuable raw material. Boulenouar explains, “We have worked with crowdsourcing clusters connected to thousands of various start-up companies to explore how we can reuse the reject to create new businesses. We present what kind of rejects we have, and it has led to discussions connected to initiatives in agriculture and bioplastic to mention a few.”

Faderco also works closely with the community to find solutions to re-use water from the municipality. At the moment they are exploring different paths and are looking at factors such as distance from the treatment facilities and quality level of the treated water. “It’s an ongoing project and we are still collecting and analyzing data to be able to consider the best solutions. It requires some deep level engineering but if we could find a way it would be very nice,” says Mr Boulenouar.

When we ask if they find support from suppliers and other organizations in this topic of creating a more circular process Mr Boulenouar answers,

Water scarcity is not unique to our region. Availability of water, and eco-friendly mills are discussed widely. To some extent we are still lacking data, but the willingness is there.”

As the demand for freshwater intensifies, businesses and communities must work together in the pursuit of a responsible resource management. Nowhere is this more apparent than in areas coping with water scarcity, where industries face a critical imperative: reduce water consumption or face the consequences. Faderco’s story of navigating water scarcity is an inspiration of how to reshape the way to operate and leading the way toward a more water-secure tomorrow. Mr Khelifa concludes,

A responsible management of water resources is a fundamental aspect of our company's values. We are committed to protecting water sources and minimizing our environmental impact.”

About Faderco

Faderco is today a major player in the national and regional personal care industry. The company has achieved a sustained growth over the last 30 years. Today, Faderco’s 2000 employees, 12 brands in 7 areas of strategic activity and 2 subsidiaries enable it to pursue its adventure and provide quality products for all.

Explore more about saving water in tissue making