Care for water: Reduce and re-use

Aug 25, 2023

Regardless of your location there are many driving forces for a tissue producer to reduce water consumption and close the water loop. It's important to understand the water balance of your mill and take control of how water is used. A large part of the populated world is experiencing water scarcity and companies have an expectation to proactively work towards reducing their water footprint for a more water-secure future.

It can be easy to assume that water is abundant because it covers 70% of our planet. However, it’s important to remember that only 3% of the world’s water is fresh water and two-thirds of that is tucked away in frozen glaciers or otherwise unavailable for our use. In other words, accessible amount of water is limited and that’s the water we need for our basic survival.

The amount of water available is not distributed evenly, in fact a large part of the populated world is experiencing water scarcity. Companies operating in industries where enormous amount of water is necessary, such as the paper industry, have an expectation to proactively work towards reducing their water footprint for a more water-secure future.

Regardless of your location there are many driving forces for a tissue producer to reduce water consumption and close the water loop. One big factor is, as mentioned above the availability of water at a specific site. The cost of water and the cost of treating excess water plays an influential role. There are also effluent regulations, lower fiber losses and higher system temperatures to consider. Making efforts to minimize usage can be beneficial for the company’s brand image.

Consequences of poor water quality

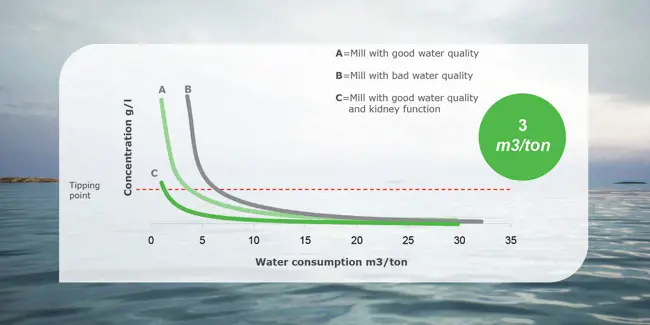

Given that the majority of our planet consists of water, why can’t we use all the water that is available? Why are we as tissue producers restricted to freshwater? Because the consequences of poor water quality, to mention a few, are the build-up of dissolved material and higher degree of deposits in the process system. Which lead to an increased amount of web breaks and deposits in paper. Producers can also be forced to consume more chemical additives. If we look at the Yankee section, here you could experience coating and wearing problems.

It's important to remember that a perfect water sample might not reflect the reality. Disturbances can occur even when all parameters, like for example alkalinity, hardness, conductivity, metal ions, pH etc. are within the recommended value. On the contrary, a few parameters can be outside the limitations without causing any short and midterm disturbances. All freshwater quality parameters interact, the process system design and the type of pulp and process chemicals used will have a positive or negative influence on the stability and the quality of the process chemistry.

Starting activities, solutions and technologies to reduce freshwater consumption

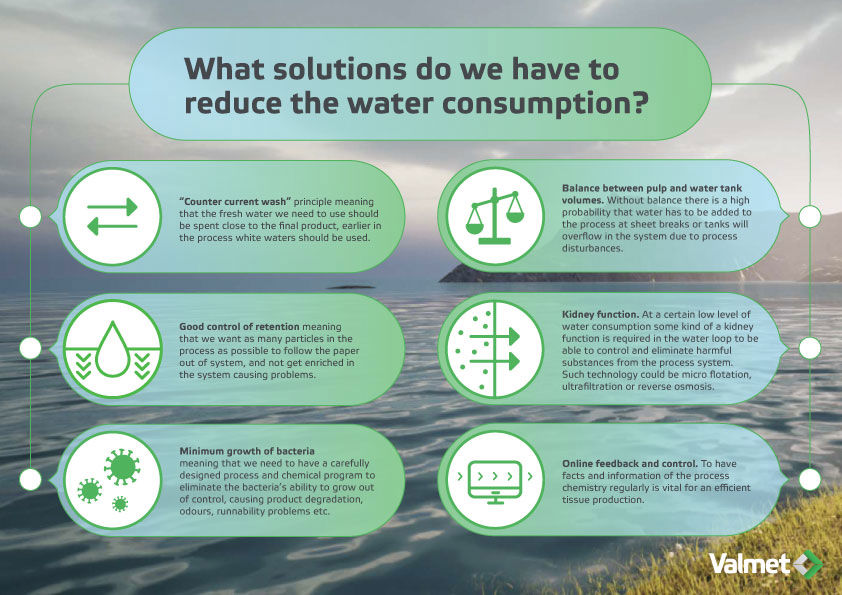

Number one is to understand the water balance of your mill and take control of how water is used in general. Subsequently you start building the process with solutions and technologies to reuse as much as possible of the water for example re-use cooling water and re-cycling water from effluent treatment.

Tissue producers should ensure to have the best process solutions available such as a closed cooling water loop and purified white water for chemical dilution instead of freshwater. Another way is to minimize rejects from stock preparation.

When considering the best technology from a water perspective a good starting point could be to use blowers instead of liquid ring pumps in the vacuum system, sealings for process equipment requiring little or no water and minimum of freshwater as shower on the tissue machine as it is standard on the DCT concepts.

In summary, there are many initiatives to improve water management in tissue production. Given the fact that freshwater is a necessity for operation it’s important to continuously improve and expand your water-saving practices. Be transparent about your efforts and share measurable results. Educate consumers and stakeholders about the importance of water conservation and collaborate with recognized environmental organizations to validate your sustainability initiatives. Because real change happens when we’re working together.

How water quality can affect your tissue mill

|

|

|

|

Learn more about how Valmet can support you on your sustainability journey