Roll grinding services for pulp drying lines

Longer running times for rolls

Valmet's roll grinding services provide precise profile and roundness shapes for rolls in pulp drying process. Maximizing the roll grinding precision means extended roll running times and minimal vibration.

Extended roll running times

Improved reliability from reduced nip load variations and roll vibrations

Better end product quality from reduced MD and CD variation

Accurate Valmet 3D roll grinding

At Valmet, grinding targets are customized according to each customer's specific requirements using advanced 3D measurement technology. Whenever possible, Valmet grinds the rolls with their roll bearings on the roll axis. This allows 3D measurement of the roll in its actual running condition.

Valmet's 3D measurement system is capable of measuring the precise roundness profile of a roll. Connecting it to a grinding head with 3D compensation allows almost perfect roundness to be achieved.

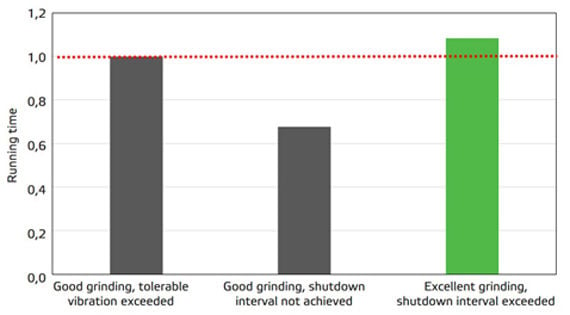

Using precise 3D measurement of the roll shape, the running time can be

linked to the grinding quality of the roll. This also means the planned shutdown interval is achieved with a safe vibration level.

Exceeding our customer's requirements

For our customers, a professional grinding service means reliable runs and cost-effective production. Knowledge and experience of Valmet's local grinding operators combined with our sophisticated equipment and truly precise 3D grinding methods enable us to continuously exceed our customers' requirements.

3D grinding results in:

- Improved reliability from reduced nip load variations and roll vibrations

- Reduced cost of roll up-keeping

- Longer roll running cycles

- Rolls stay in better shape in use

- Less cover material removal needed

- More run cycles between re-coverings

- Better end product quality from reduced MD and CD variation

Roll grinding services close to you

In order to achieve strict dimensional tolerances and surface finish requirements, Valmet's roll service centers round the world utilize the latest equipment and up-to-date expertise. With more than 50 advanced grinding machines, we can meet the specific needs of our customers and transform our global expertise into local competence. Continuous development in grinding technology leads to better roll cover performance and extended running times.

Questions?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

CONTACT USOnline support for optimized grinding quality

By going mobile with remote access to all our grinding machines, Valmet’s specialists are able to perform grinding analyses and give on-time support to our grinding operators. This allows grinding quality to be optimized, wherever the service is taking place.