Workshop services for wood handling

Services for high quality and optimal capacity

Workshop services ensure high availability and optimal performance of your equipment in the chipping process.

Uniform chip quality

Optimal capacity

Workshop services for wood handling offer full scope reconditioning at Valmet workshops globally to return the equipment performance to the original level and beyond with upgrades. With modular maintenance solutions, the optimal lifetime can be achieved.

Questions?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

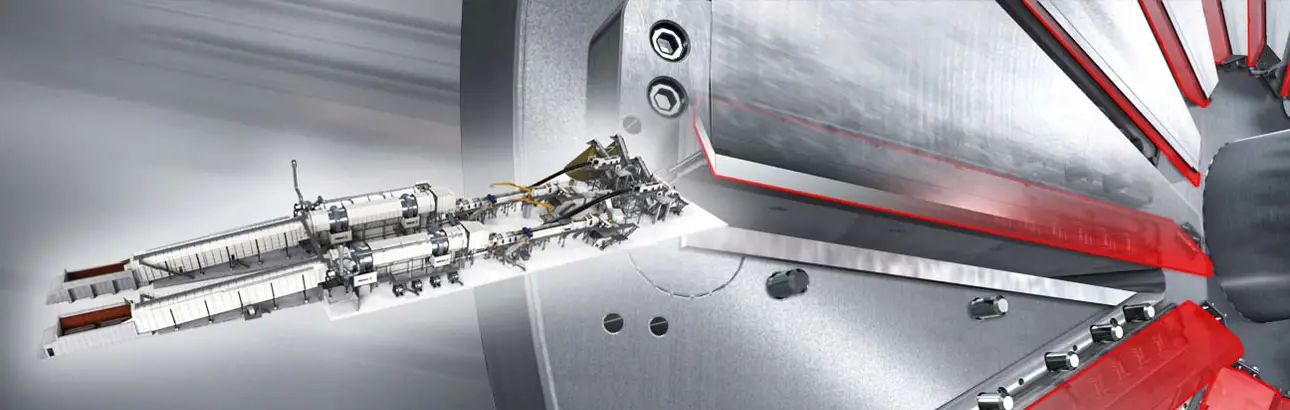

CONTACT USChipper disc reconditioning

The typical Valmet chipper annual throughput is millions of tonnes of logs in harsh operating conditions. The recommended reconditioning program with a five- to seven-year interval reduces the risk of failure and secures very short payback because of savings in white wood losses, consistent chip quality and optimal capacity. In addition, chipper knife runout and knife clearance setting can be done after reconditioning as per OEM recommendations.

Bedknife reconditioning

Periodic reconditioning results in consistently high chip quality, the maximum service life and excellent availability.

It’s good to combine Bedknife reconditioning with Bedknife pocket reconditioning at an interval of five to 10 years.

Read more about Valmet Bedknife Pocket Reconditioning.

Feed spout reconditioning

Reconditioning extends the spout service life. Valmet Feed Spout Reconditioning guarantees the original dimensions, stabilizing log feeding to the chipper. Maintaining the spout top surface and keyway’s condition underneath results in steady log feeding and a perfect connection to the foundation, which are key factors for any chipper spout.

Exchange unit agreement – a powerful risk management tool

Finding a balance between risk and costs in the spare equipment inventory can be difficult. Valmet’s Exchange Unit Agreement is an alternate solution that eliminates the need to purchase your own spare equipment. The agreement ensures dedicated equipment in perfect condition is always available to the customer. Agreements are established based on each customer’s needs. Agreements are powerful risk management tools with known annual costs.

Related pages