Flow control for nickel

Valves and pumps for nickel autoclave high pressure acid leaching

Autoclaves are used in mining and minerals processing to extract metals from refractory ore bodies. A typical process for autoclaves is high-pressure acid leaching (HPAL), which is often used to extract nickel from laterite ore bodies, but it can also be applied in copper and cobalt production. Valmet has a wide range of valves, pumps and services for HPAL process.

A trusted partner for the world’s toughest valve applications

Improved safety and reliability of HPAL process

Valve solutions tested and field-proven in numerous mining applications

Expert technical support and service in over 40 countries around the world

Nickel laterites processing with HPAL technology

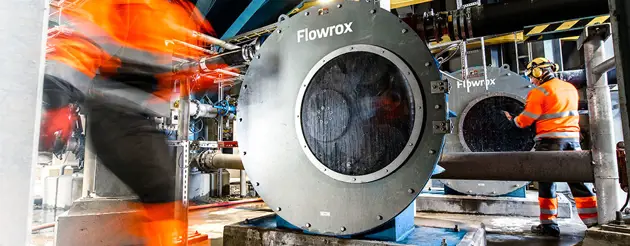

In the HPAL process, ore is first crushed and mixed with water to create a slurry that is preheated and fed into an autoclave. Acid is then added to the vessel to react with the slurry. The HPAL process utilizes high temperatures (approximately 250 °C/480 °F) and high pressures (40–60 bar/580–850 psi) to facilitate leaching.

After the autoclave processing, the slurry is returned to atmospheric condition by taking it through two or more letdown stages and a neutralization circuit. Once at atmospheric condition, the slurry moves to downstream processing where the metal can be recovered from the liquid portion.

Improving reliability with optimal valves and pumps for nickel autoclave high-pressure acid leaching

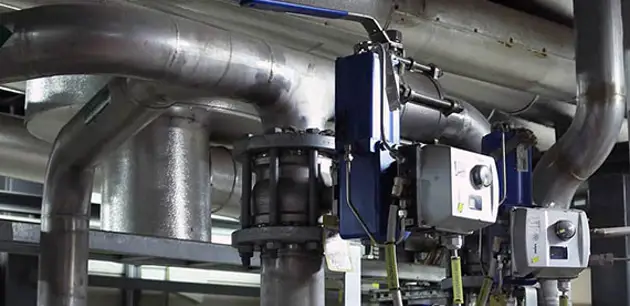

Autoclave HPAL is a challenging process requiring the toughest flow control solutions. Temperatures and pressures are extremely high, and acidic media and abrasive solids increase the wear and tear of the equipment. An optimal HPAL operation generally uses several different types of valves, such as slurry feed and discharge valves, pump isolation valves, depressurization valves, steam supply and steam drum isolation valves, as well as acid injection valves.

Valves and pumps for slurry feed

The conditions that valves and pumps face in the HPAL process require the highest possible resistance against corrosion and erosion as well as against deterioration caused by solids. Selecting the right material, seat and coating is vital in maintaining the sealing abilities of slurry feed valves.

Valves for acid feed

Controlling the acid feed is essential in the HPAL process. Valves must provide absolute isolation. If unstable situations occur, the valves and other process equipment in the acid feed line must be able to resist very high concentrations of acid.

Valves for depressurization

Autoclave processes are occasionally depressurized as a result of operational disturbances, emergency situations or maintenance. During depressurization, a vent line is used to reduce pressure and temperature inside the autoclave. Careful consideration of valve materials and coatings are among the top priorities when selecting the valves for this service.

Downloads

Valves, pumps, valve automation and services for nickel production

Flow control for different applications in mining and minerals processing