A state of the art in winding

Advantage SoftReel B

The Advantage SoftReel™ B is an innovative winding system that provides producers and converters of premium tissue and towel grades a competitive edge.

Long and soft nip

The short and hard nip in conventional reels is replaced with a long and soft nip against a belt. This creates a possibility to run with a lower nip pressure that helps both to preserve bulk and makes turn-ups more forgiving.

Unique load control

The SoftReel B uses a unique load control that measures the actual impingement of the roll into the belt. This gives the most accurate load control independent of mechanical friction in all moving parts.

Smooth turn-ups

A hard nip against a reel drum can cause the tail to explode during threading, but the SoftReel B allows winding with a lower nip pressure, reducing this risk. Another advantage is that the risk for loose cores is reduced since the roll can grow into the belt during threading and turn-up.

Smooth take over

Since both the primary and secondary winding system use only one common winding feedback signal, the belt impingement, the transition between them will be very smooth.

The B makes the difference

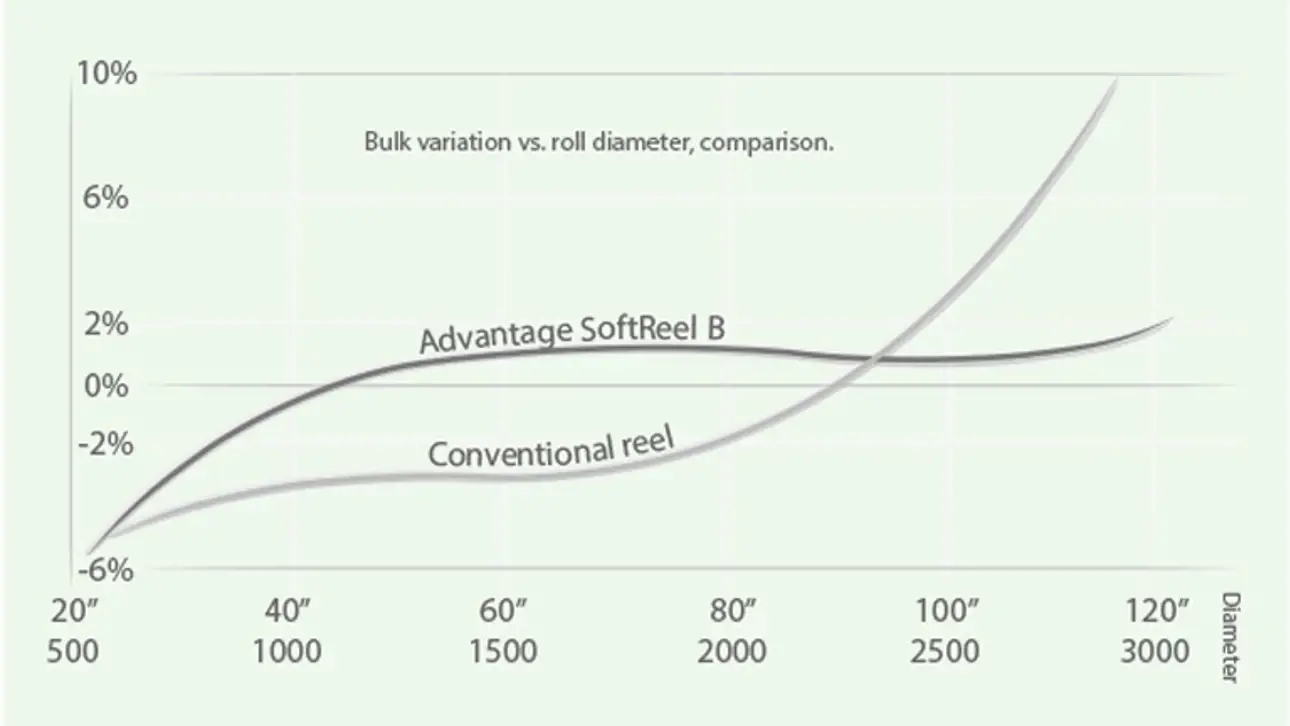

The B in Advantage SoftReel B stands for Belt and it is the belt in this tissue winding technology that gives producers and converters the control over the winding process that allows producing large diameter parent rolls while keeping exceptionally uniform caliper throughout a whole roll.

In the SoftReel B the paper roll is winded against a belt loop generating the most gentle, accurate and forgiving winding method in the industry.

SoftReel B is equipped with linear primary arms and secondary carriages with CWA, a short belt run with a stretcher and guide mechanism.

Replacing an old winding principle…

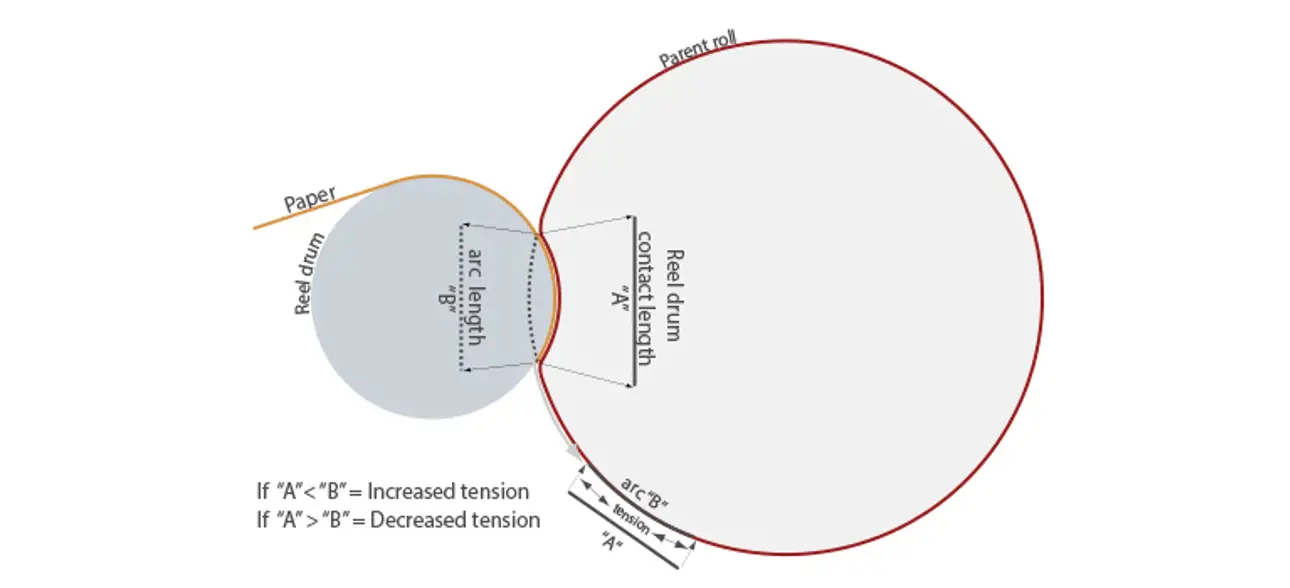

Using conventional technology for winding low-density paper such as premium tissue and towel grades does not produce the same good results as when winding high-density paper.

When low-density paper is fed into a nip consisting of a reel drum and the parent roll, the length of contact, “A” of the parent roll being wound becomes longer as the diameter of the roll increases, making the wound-in tension in the roll continuously lower. Consequently, these parent rolls are not of uniform caliper throughout, which limits the diameter and the speed at which they can be wound, but also unwound in converting lines.

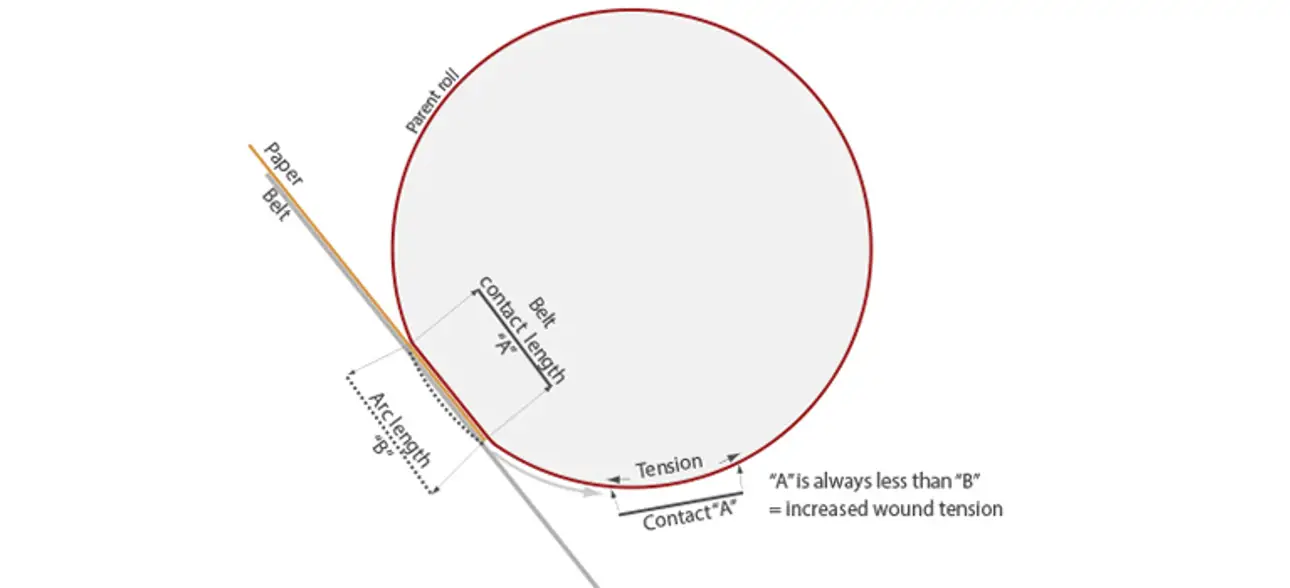

...leads to consistent control

Replacing the reel drum with a belt changes the physical nature of the nip. Instead of a round, hard-surfaced reel drum and parent roll, SoftReel B technology enables the tissue and towel grades to meet a flat, soft-surfaced belt in the nip. In other words, the length of contact “A” is always shorter than the arc “B” even as the diameter of the roll increases. When the tissue exits the nip, the sheet is elongated and thus tension is generated inside the roll. The result is consistent control of the wound-in tension. Therefore, SoftReel B can produce uniform large parent rolls.

New or rebuild

SoftReel B is an alternative to the problems of conventional winding that tissue makers have traditionally accepted as part of the process. Also, SoftReel B is a mature technology available as an option for all new and existing Valmet tissue machines as well as for installation on tissue lines from other suppliers as an upgrade or rebuild.

+ 100

Advantage SoftReels delivered world-wide over the last 15 years